Tower crane foundation for construction and manufacturing method thereof

A technology of tower crane foundation and manufacturing method, which is applied in construction, infrastructure engineering and other directions, can solve the problems of decreased waterproof performance of buildings, difficult installation of tower cranes, large amount of earthwork construction, etc., maximize the utilization rate of machinery, solve the problem of tower crane attachment, reduce the effect of structural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

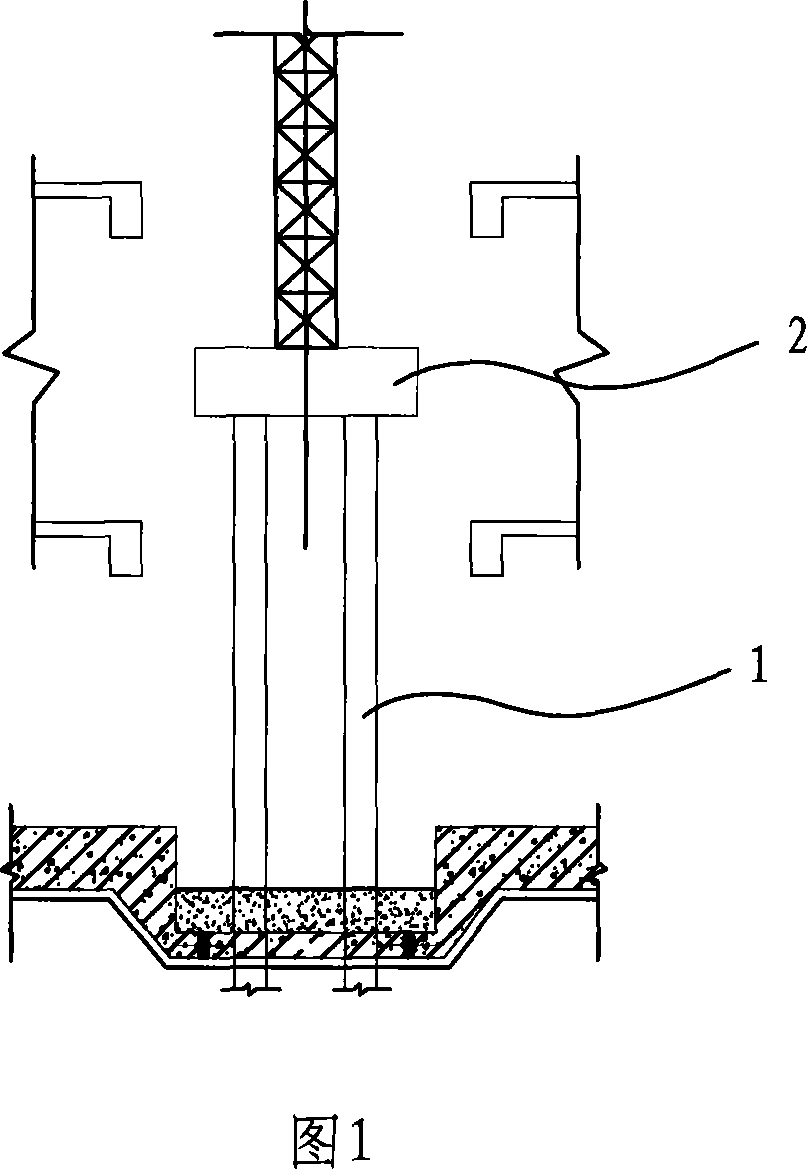

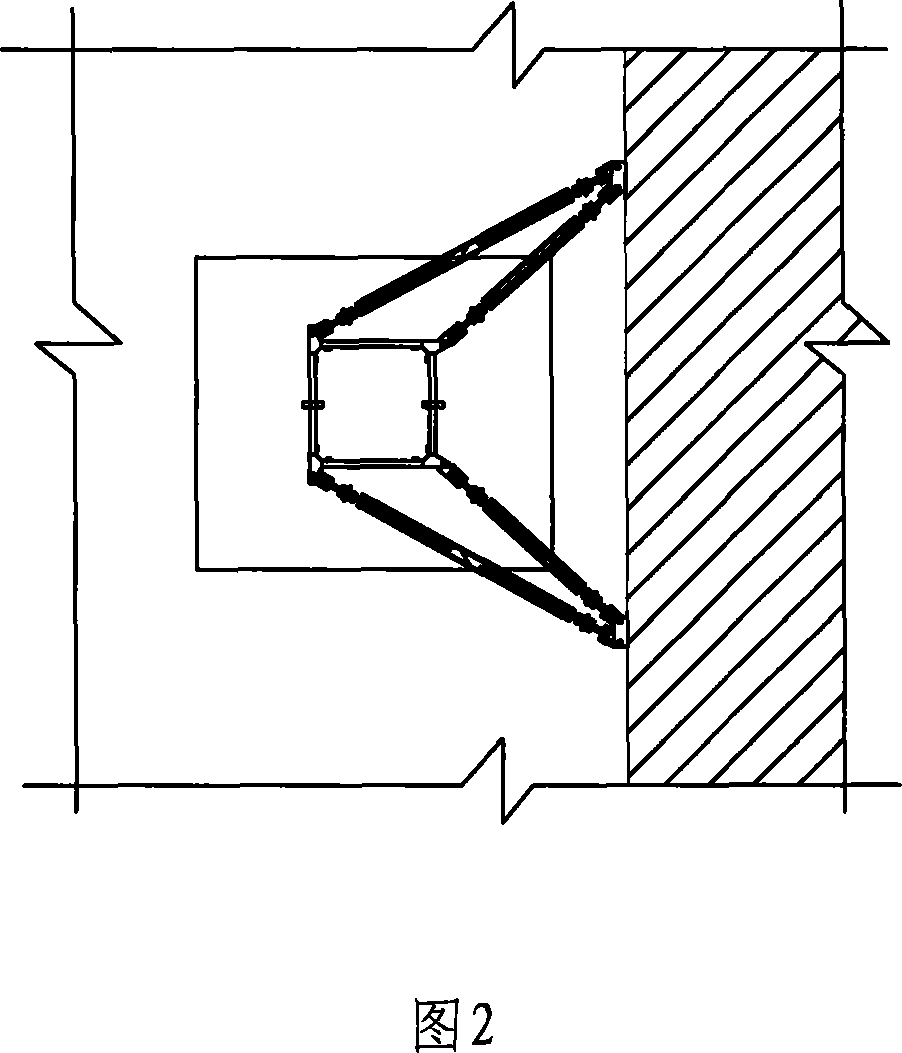

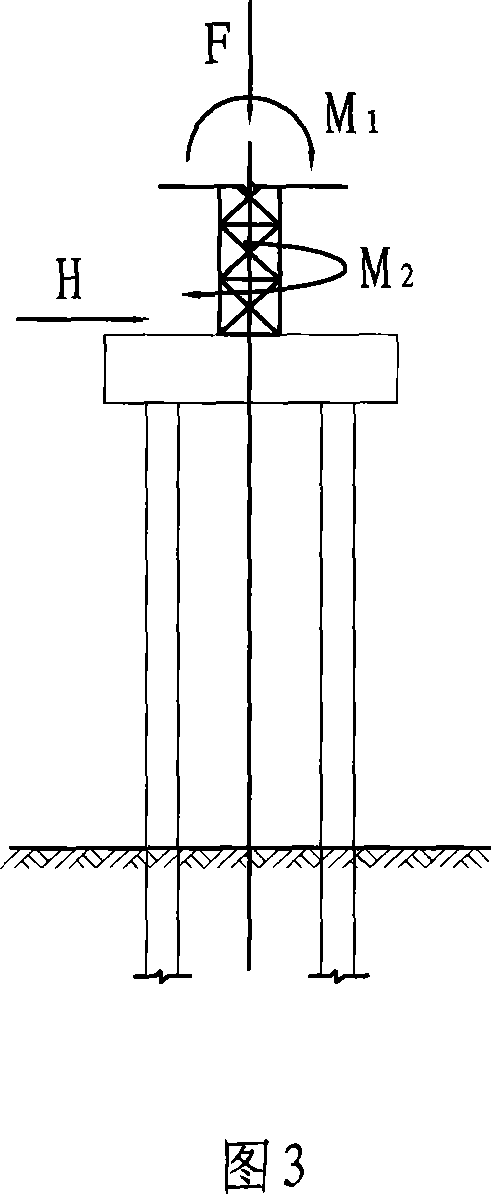

[0033] Embodiment 1: Referring to accompanying drawings 1 to 9, a tower crane foundation for construction includes a tower crane foundation cap 2 and four cast-in-situ piles 1 fixedly connected to the bottom of the tower crane foundation cap. The height of the exposed base under the position is 5-7 meters, and a water-stop structure is arranged between the cast-in-place pile and the building floor.

[0034] The water-stop structure of this embodiment is that an advanced water-stop plate 3 is fixedly connected with the four cast-in-place piles, and a water-swelling water-stop strip 4 is arranged between the cast-in-place piles and the advanced water-stop plate. The building bottom plates are connected by elastic material components, and the settlement space is reserved between the advanced water stop plate and the building bottom plate poured after the upper part; Rubber waterstop 5, polyvinyl chloride mastic 6 on the foamed plastic board 7 and the outside of the rubber waterst...

Embodiment 2

[0132] Embodiment 2: Referring to accompanying drawings 10 and 11, a tower crane foundation for construction includes a tower crane foundation cap 2 and four cast-in-situ piles 1 fixedly connected to the bottom of the tower crane foundation cap. The height of the exposed base under the position is not less than 3 meters, and a water-stop structure is arranged between the cast-in-place pile and the building floor.

[0133] The water-stop structure of this embodiment is an additional cap 8 connected to the lower part of the building floor, and a water-expandable water-stop strip 4 is arranged between the additional cap and the cast-in-place pile, and the additional cap is poured together with the building floor.

[0134] This embodiment is applicable to the occasion where the building adopts the engineering pile foundation, and its manufacturing method is similar to Embodiment 1, wherein, the difference is the treatment of the bottom plate, and the technological process of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com