Pile box barrel composite foundation for offshore wind power and construction method thereof

An offshore wind power and composite foundation technology, applied in infrastructure engineering, construction and other directions, can solve the problem that the negative pressure bucket foundation cannot reach the design level, etc., and achieve the effects of high construction efficiency, short operation window period and significant benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

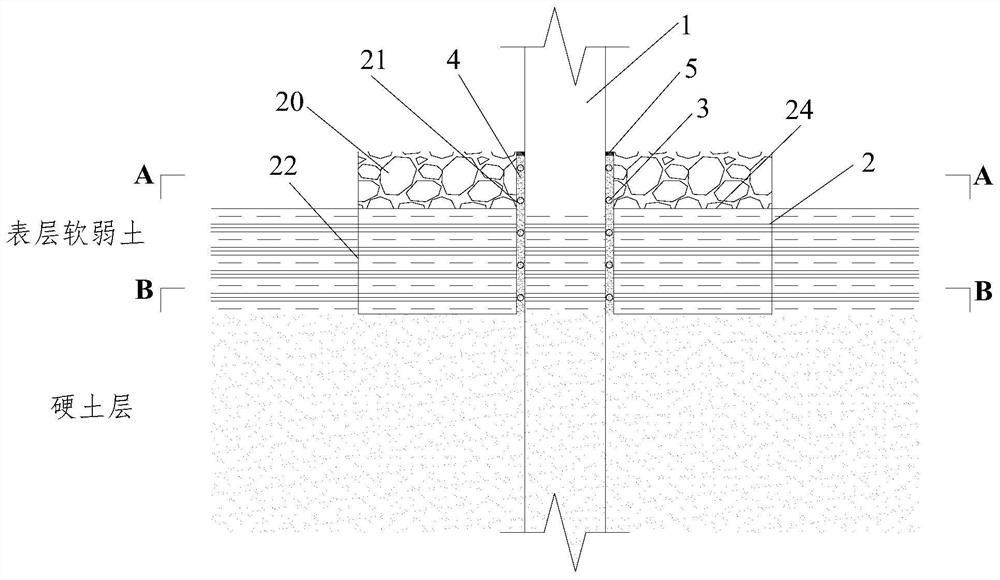

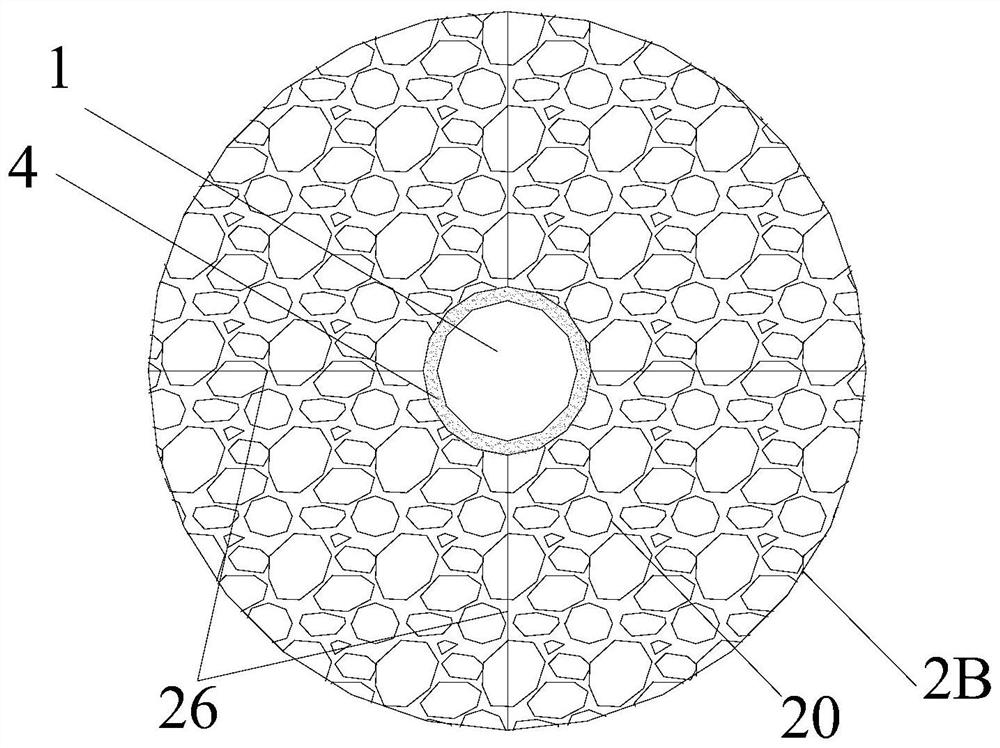

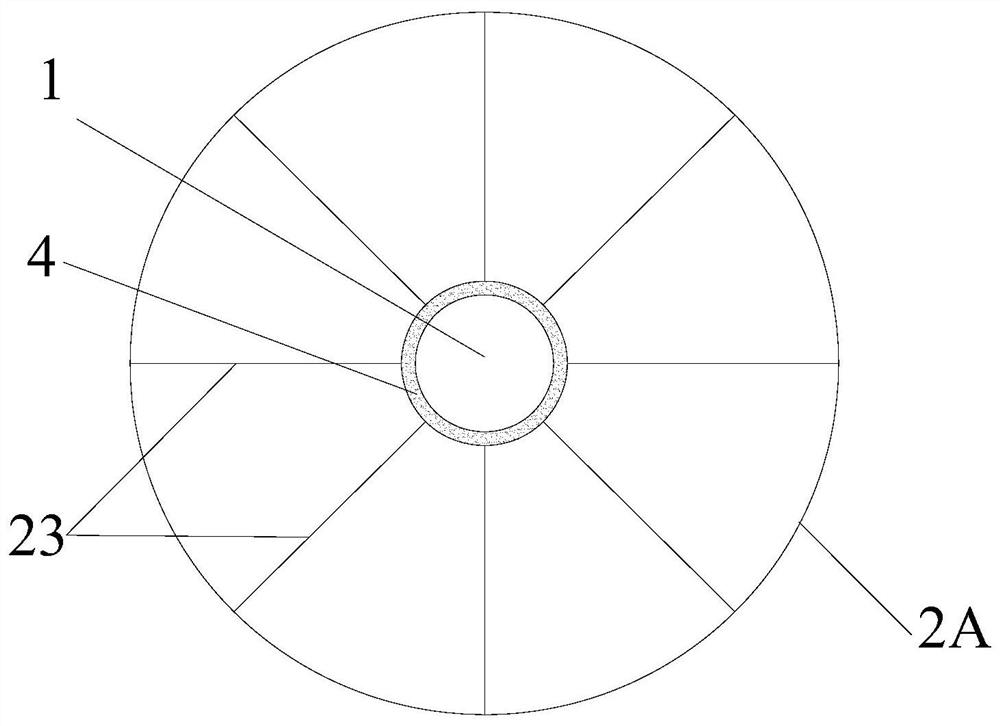

[0034] see Figure 1 to Figure 3 , the pile-box-barrel composite foundation for offshore wind power of the present invention includes a single pile 1 and a barrel body 2; wherein,

[0035] The single pile 1 is driven into the seabed soil and has the ability to resist vertical loads;

[0036] The barrel body 2 includes an inner barrel body 21, an outer barrel body 22, eight negative pressure barrel partitions 23 and a negative pressure barrel top plate 24;

[0037] The inner diameter of the inner barrel 21 is greater than the outer diameter of the single pile 1; the inner barrel 21 is coaxially arranged in the inner cavity of the outer barrel 22; the barrel 2 is sleeved on the single pile 1 through the inner barrel 21; the inner wall of the inner barrel 21 Also install the series guide pulley 3 evenly, the inner diameter formed by the rim of the series guide wheel 3 is ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com