Method for preventing surface collapse when shield tunneling machine starts and immediately underneath passes existing shield tunnel

A technology of shield tunneling and shield machine, which is applied in the field of Ming Dynasty, can solve problems such as inability to construct and difficult construction, and achieve the effects of low construction accuracy, convenient replacement, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

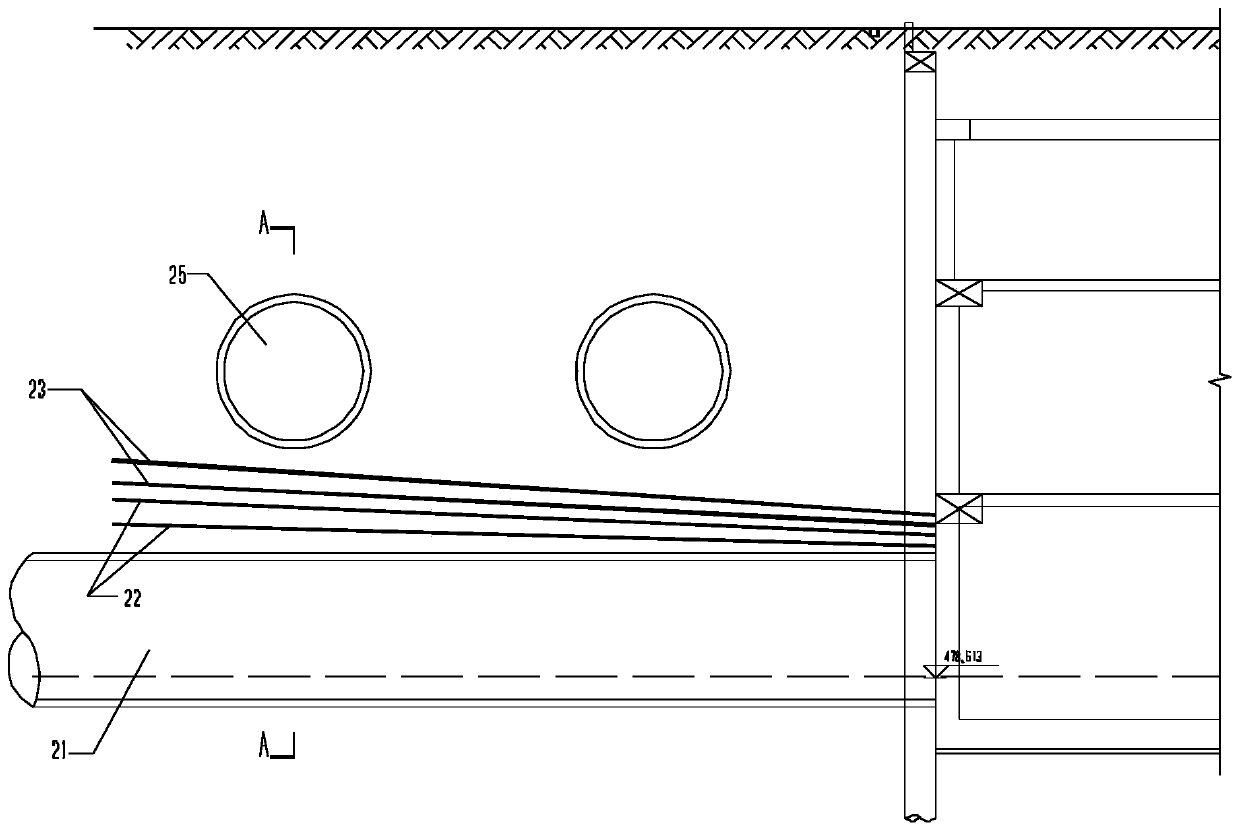

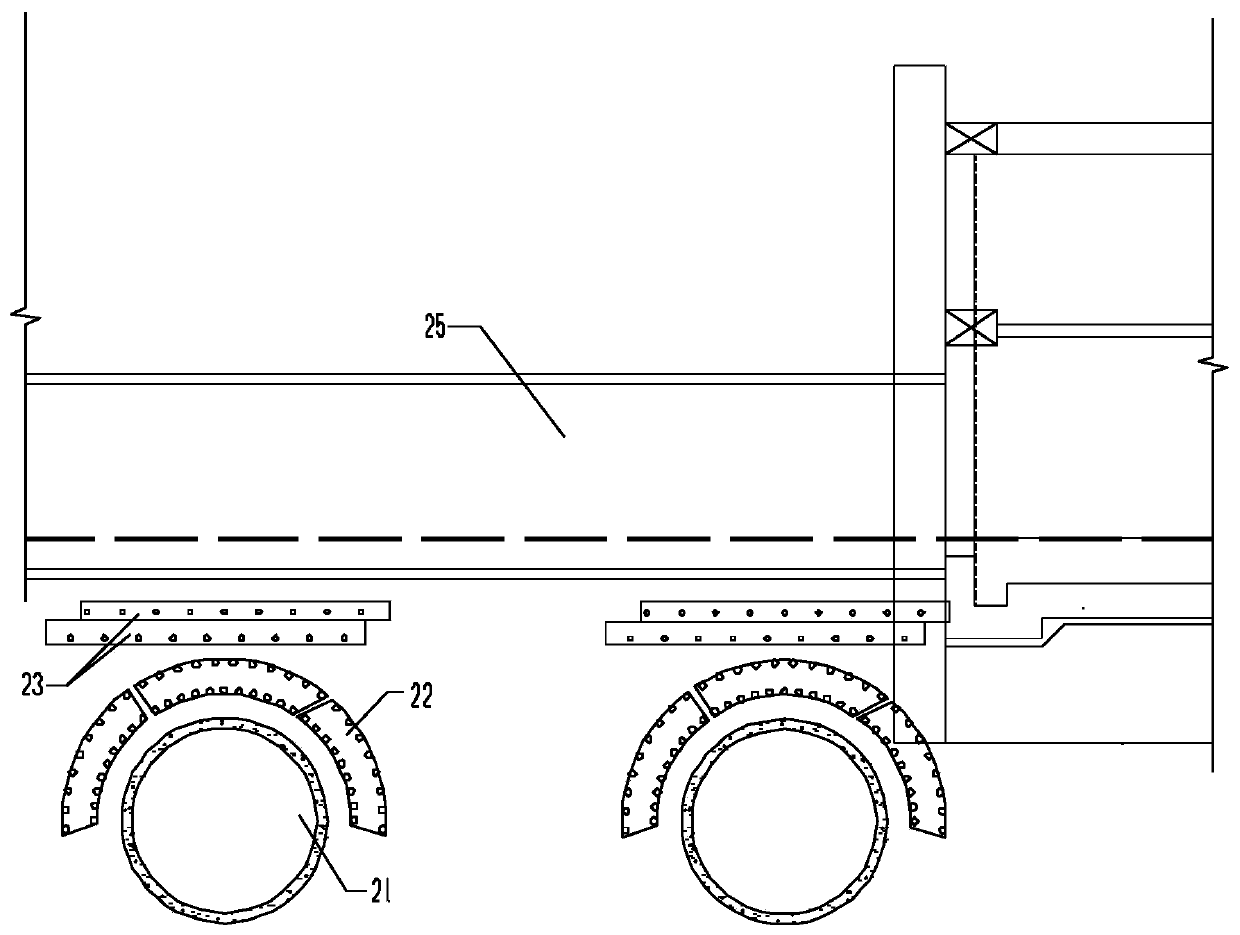

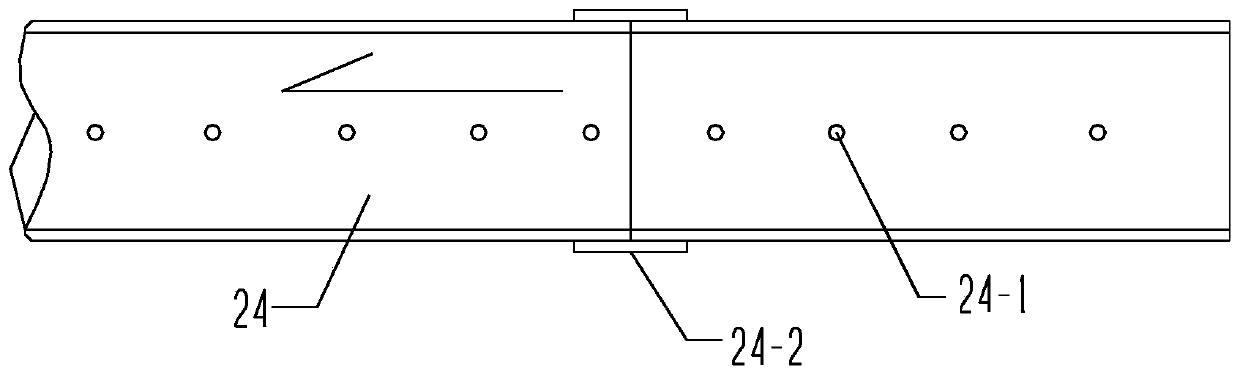

[0062] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0063] The embodiment is based on the specific construction site where the shield tunneling of a certain section of Metro Line 6 passes under the existing Line 3. The length of the left line of this section is 823.842m, and the length of the right line is 821.940m. The distance between the starting station and the outer end wall of the main body of the existing Line 3 is 8m, and the length of the forward penetration is 20m. 1~28 is the underpass and high-risk section. The buried depth of the shield tunnel at the underpass is 20.39m. The vertical spacing of tunnels is 4.065m. The groundwater in the lower section is relatively rich. This section is located in the first-level terrace of the alluvial plain of the Minjiang River system. The surface water is Fuhe water. The groundwater is mainly the upper stagnant water, Quaternary sand, and pebble soil in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com