Row-frame-type hydrophilic platform cylinder vertical retaining wall seawall structure

A water platform and bent-frame technology is applied in the field of cylindrical upright retaining wall seawall structures of bent-frame hydrophilic platforms, which can solve the problem that the construction quality of the underwater part is difficult to control, the effective utilization of land resources is unfavorable, and the volume of the earth-rock embankment is large. and other problems, to achieve the effect of being conducive to effective utilization, strong ability to adapt to uneven settlement, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

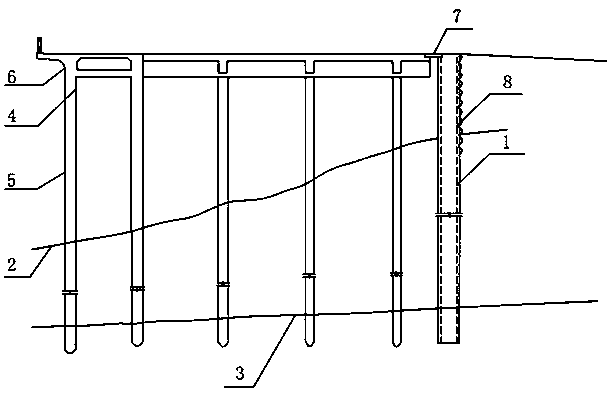

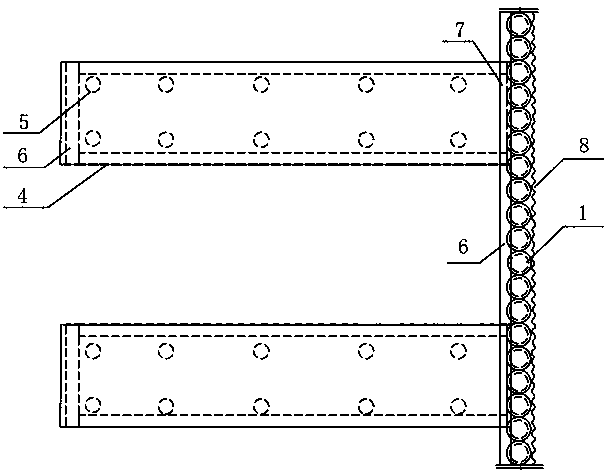

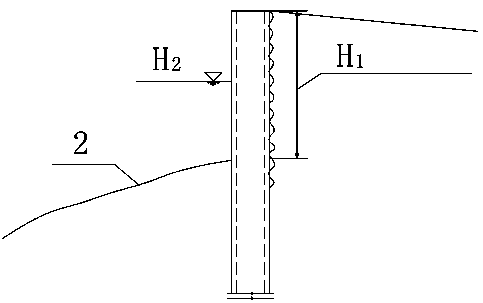

[0020] like Figure 1-2 As shown, the vertical retaining wall seawall structure of the bent-type hydrophilic platform cylinder includes a vertical retaining wall 1, and the lower part of the vertical retaining wall 1 goes deep into the foundation bearing layer 3 to realize the fixed and non-slip retaining wall. Type retaining wall 1 is a "1" type thin-walled cylindrical structure arranged continuously. The wall is made of reinforced concrete, and earth can be filled in the middle. like image 3 As shown, the cylinder wall thickness and inner and outer diameters of the "1" thin-walled cylinder structure are determined through calculation by parameters such as the thickness of the soil layer behind the retaining wall, bulk density and steel bar properties, that is, the cylinder wall thickness D=f(H 1 ,H 2 ,γ m ,f y ,A), where H1, γ m is the thickness and weighted avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com