Pre-perforated lateral restraint pile and construction method thereof

A technology of lateral restraint and construction method, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of large emissions, environmental pollution, and high construction cost, improve the bearing capacity of the foundation, and the length of the pile can be controlled and adjusted. , Provides the effect of anti-pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

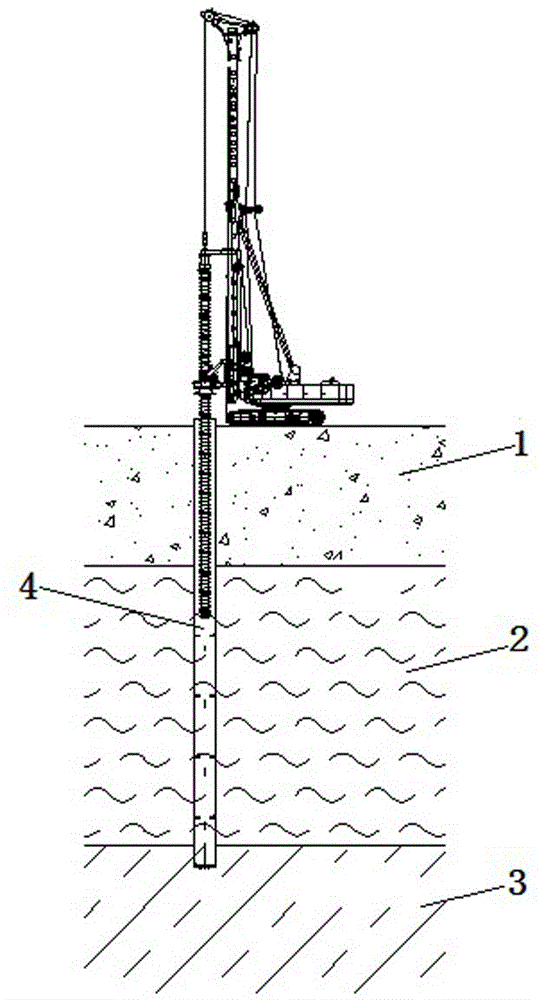

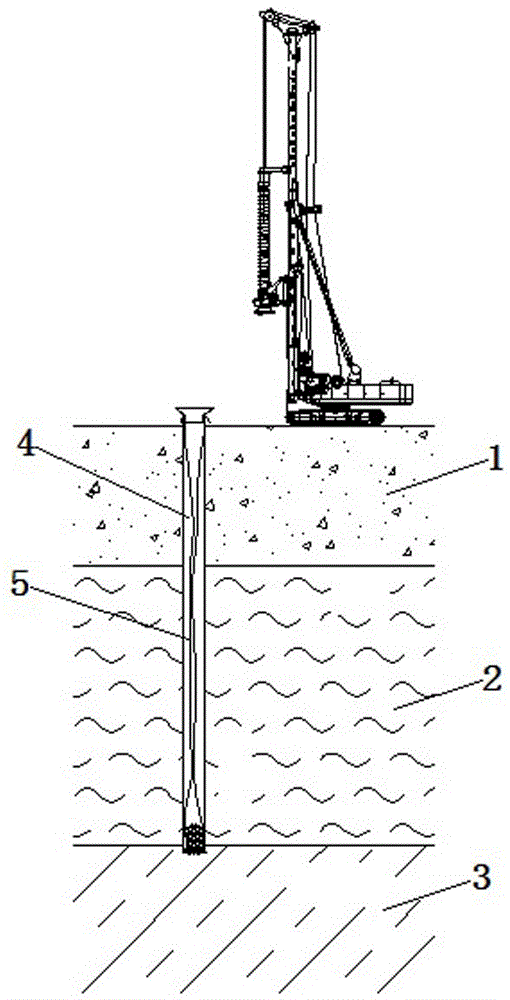

[0050] Embodiment: the preformed hole lateral restraint pile in the present embodiment comprises reinforced filter screen 5 and coarse particle filler 6, and coarse particle filler 6 is wrapped in the inside of reinforced filter screen 5, makes reinforced filter screen 5 to coarse particle Filler 6 produces lateral restraint and has good integrity.

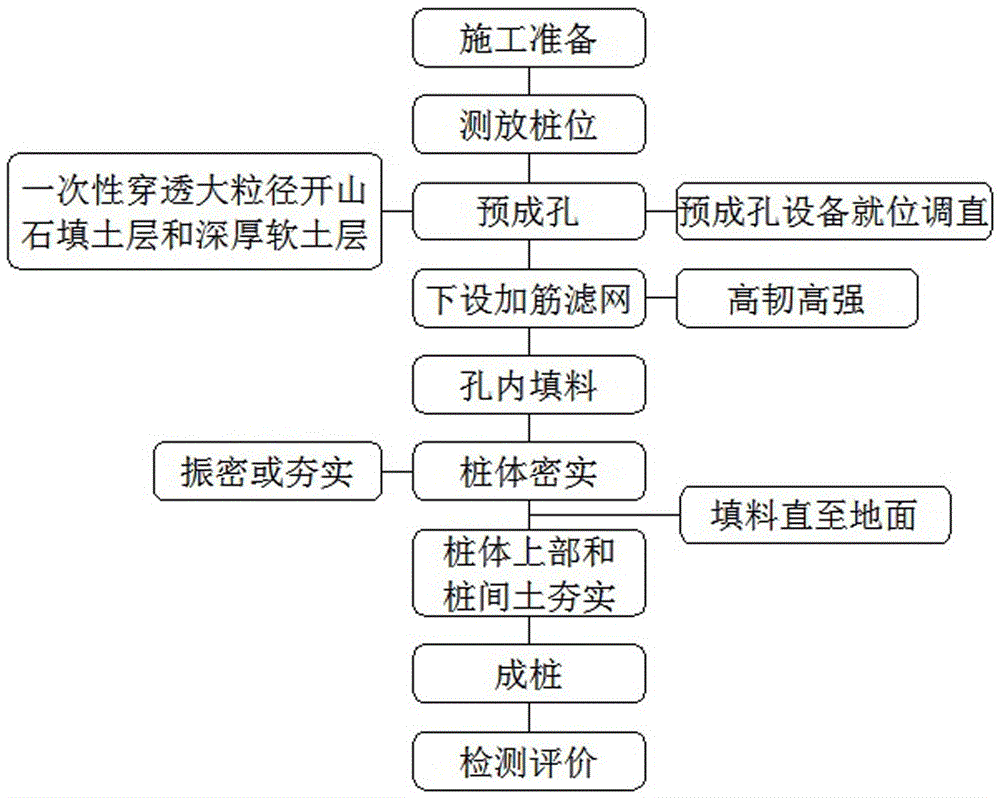

[0051] The prefabricated hole lateral restraint pile in the present embodiment has the following steps during concrete construction:

[0052] 1. Design:

[0053](1) The design parameters of the preformed hole deep layer dense large-diameter laterally restrained coarse particle filling pile method include: pile hole diameter, pile diameter, pile distance, pile length, vibration frequency of vibrating rod and vibration density time (or compaction energy level and Rammer diameter), outer pipe pull-up speed, diameter and strength of reinforced filter, foundation treatment requirements (foundation bearing capacity, deformation modulus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com