Pre-hole-forming padding substitution hammer flattener dynamic compaction method

A technology of pre-forming holes and dynamic tamping, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc. It can solve problems such as difficulty in effectively landing the bottom, and achieve the effects of short construction period, remarkable treatment effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

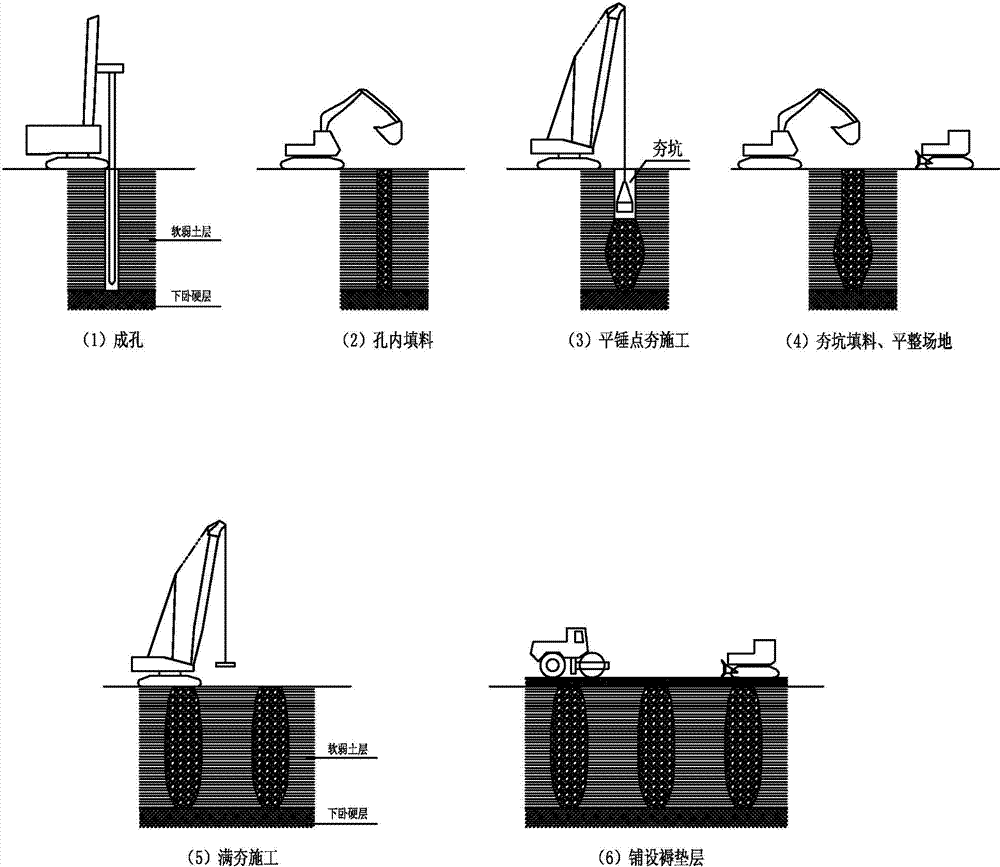

[0056] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown:

[0057] A pre-formed hole filling replacement flat hammer dynamic compaction method, which pre-forms holes before dynamic compaction construction:

[0058] Holes are formed in the foundation soil by drilling machines such as rotary drilling rigs and long auger drilling rigs;

[0059] Directly penetrate the soft soil layer to the top surface of the underlying hard layer or enter the underlying hard layer.

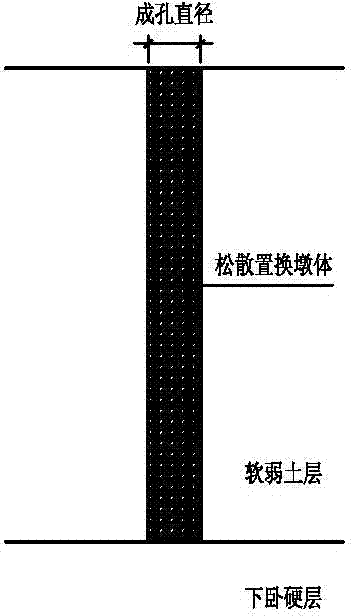

[0060] It forms a loose displacement pier before dynamic compaction construction:

[0061] Fill the hole with stones, gravel, coarse sand and other materials;

[0062] Continuously backfill to the elevation of the orifice to form a loose replacement pier;

[0063] The loose replacement pier is a good drainage channel, which is conducive to accelerating the consolidation of soft soil;

[0064] The loose replacement pier is in good contact with the underlying hard layer.

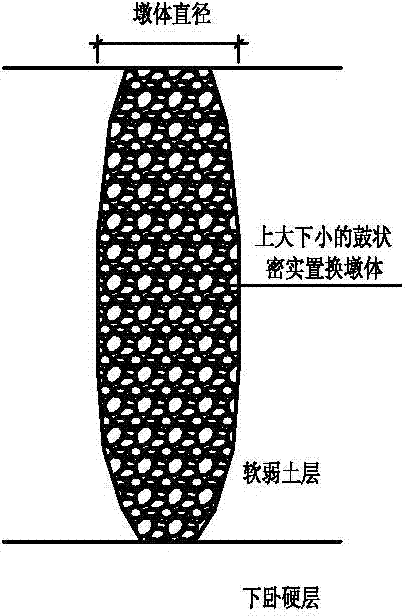

[0065] It uses dynam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com