Digging, spraying, pressing and grouting pile and construction method and special drilling machine thereof

A construction method and technology of grouting piles, which are applied in the direction of earth drilling, rotary drilling rigs, drilling equipment and methods, etc., and can solve problems such as small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

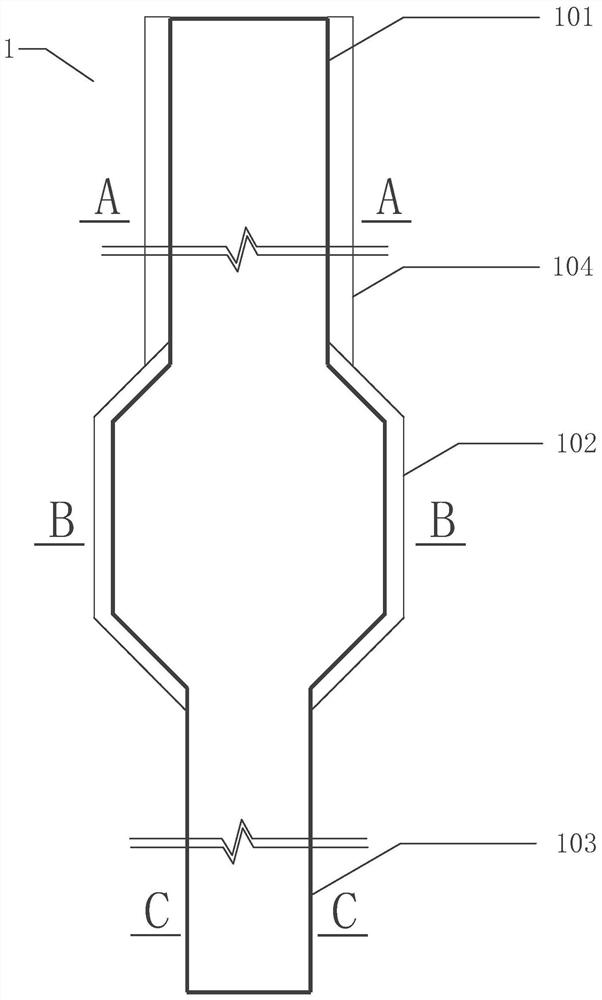

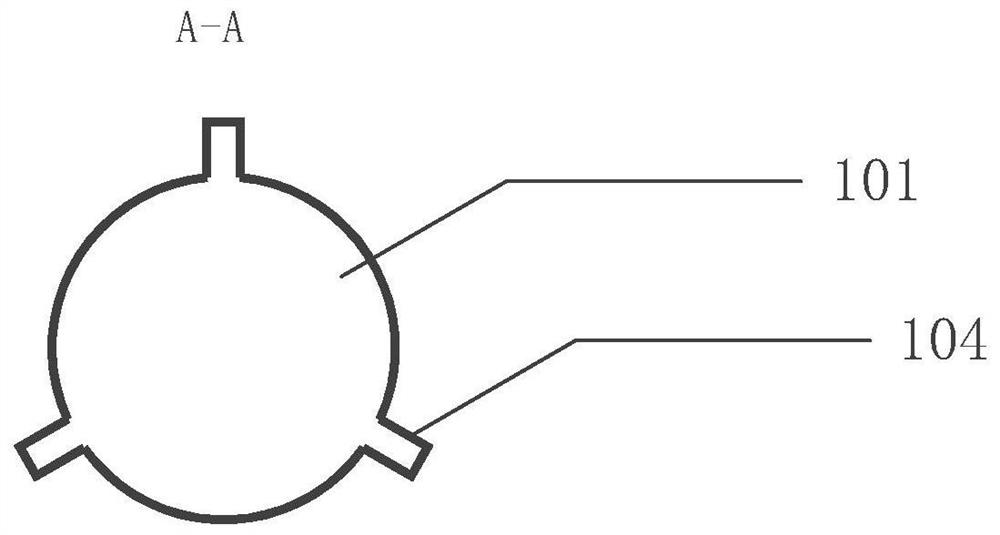

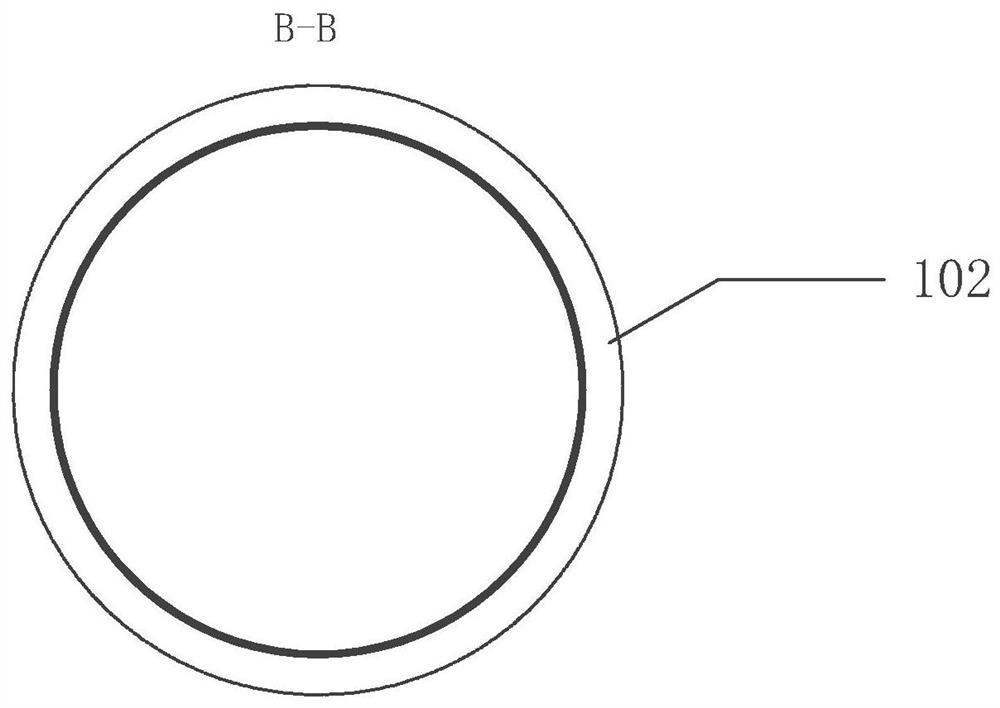

[0029] Such as Figure 1-4 As shown, the present invention digs and sprays pressure grouting piles, and its pile body 1 includes a pile body 101, a double-conical frustum expanding body 102 and a pile end 103, and a steel cage is arranged in the pile body 1, which is located above the double-conical frustum expanding body 102 The pile body 101 is provided with a wing plate 104 perpendicular to the axis of the pile body 1. The width of the wing plate 104 is 8 to 15 cm, and the thickness is 15 to 30 cm. 20-50cm.

[0030] Such as Figure 5 Shown, the construction method of the present invention digs spray pressure grouting pile, comprises the following steps:

[0031] (1) First use the special drilling rig for digging, spraying and pressure filling piles to drill to the design depth, and the soil scraping blade 9 will automatically extend when the drill pipe is lifted;

[0032] (2) Adjust the pressure of the nozzle 10 and the lifting speed, and simultaneously spray the cement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com