Patents

Literature

83results about How to "Conducive to environmental protection and energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

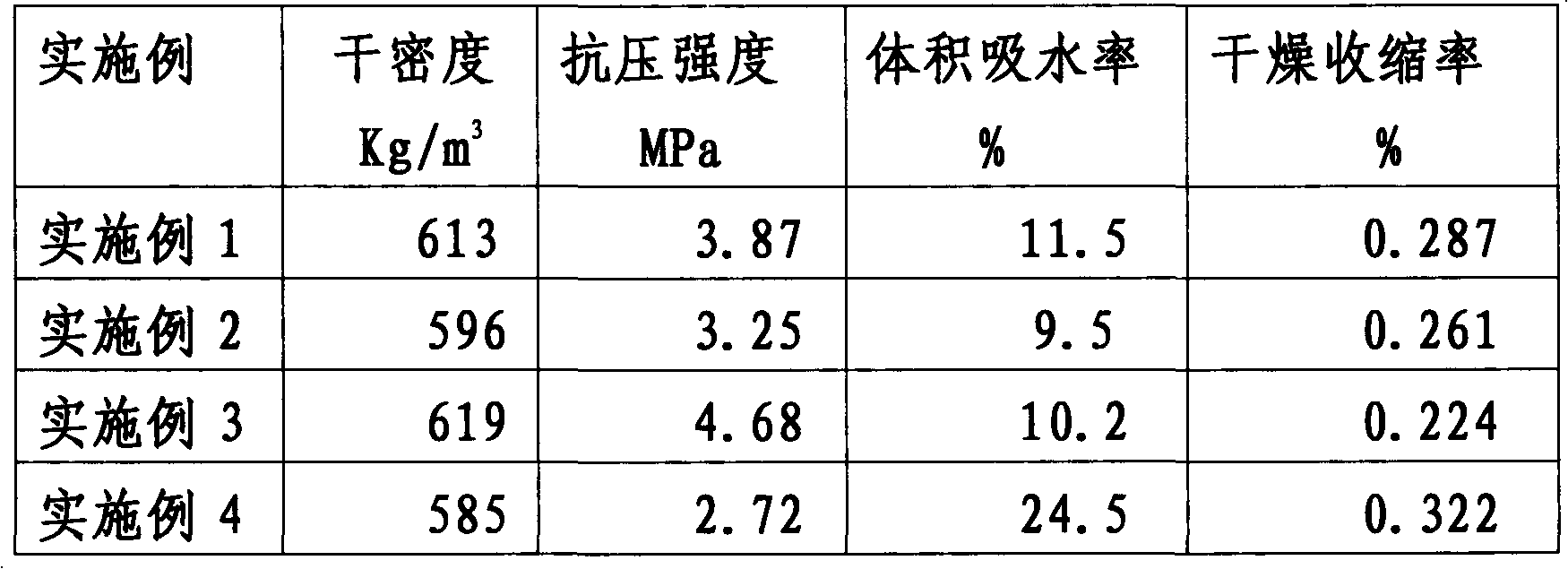

Flame retardant heat-insulation foam concrete and preparation method thereof

The invention discloses flame retardant heat-insulation foam concrete which consists of the materials by mass as follows: 30-60 parts of cement; 30-70 parts of coal ash; 10-40 parts of mineral powder; 0.05-1. 0 part of water reducing agent; 0.02-0.2 part of cellulose ether; 0.05-1.0 part of water repellent; 1-10 parts of anhydrous anhydrite; 0.06-0.2 part of polypropylene fiber; 0.1-0.4 part of foaming agent; and 0.30-0.60 part of water. The advantages are as follows: the foam concrete has high strength, low shrinkage and good water repellent property; the heat insulation performance is good and can meet different heat-insulation requirements of buildings; the preparation technology is simple; and industrial wastes such as coal ash, mineral powder and the like are utilized fully, and the flame retardant heat-insulation foam concrete has excellent environment-protection effects of utilizing waste, saving energy and the like, as well as better economic benefit.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

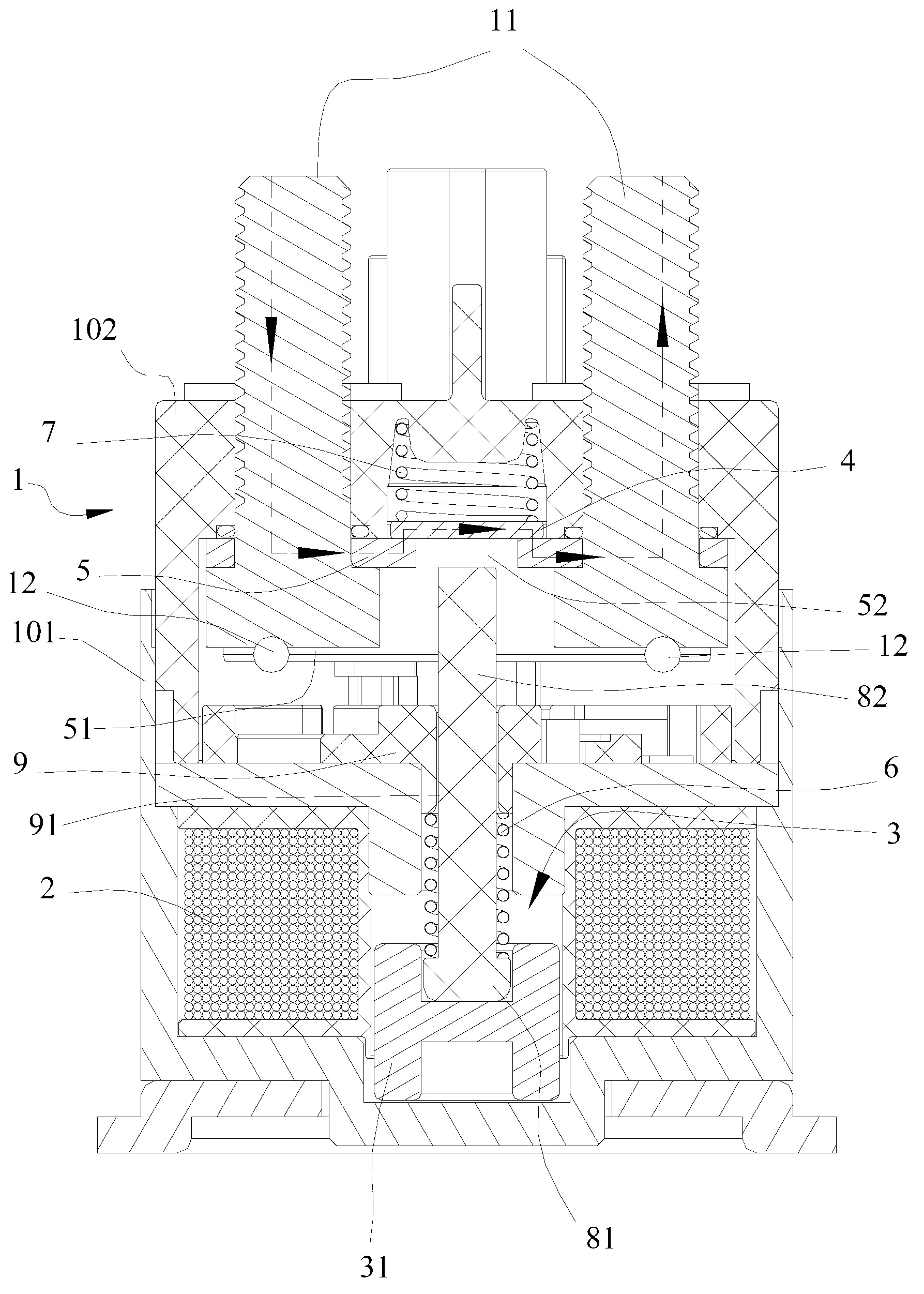

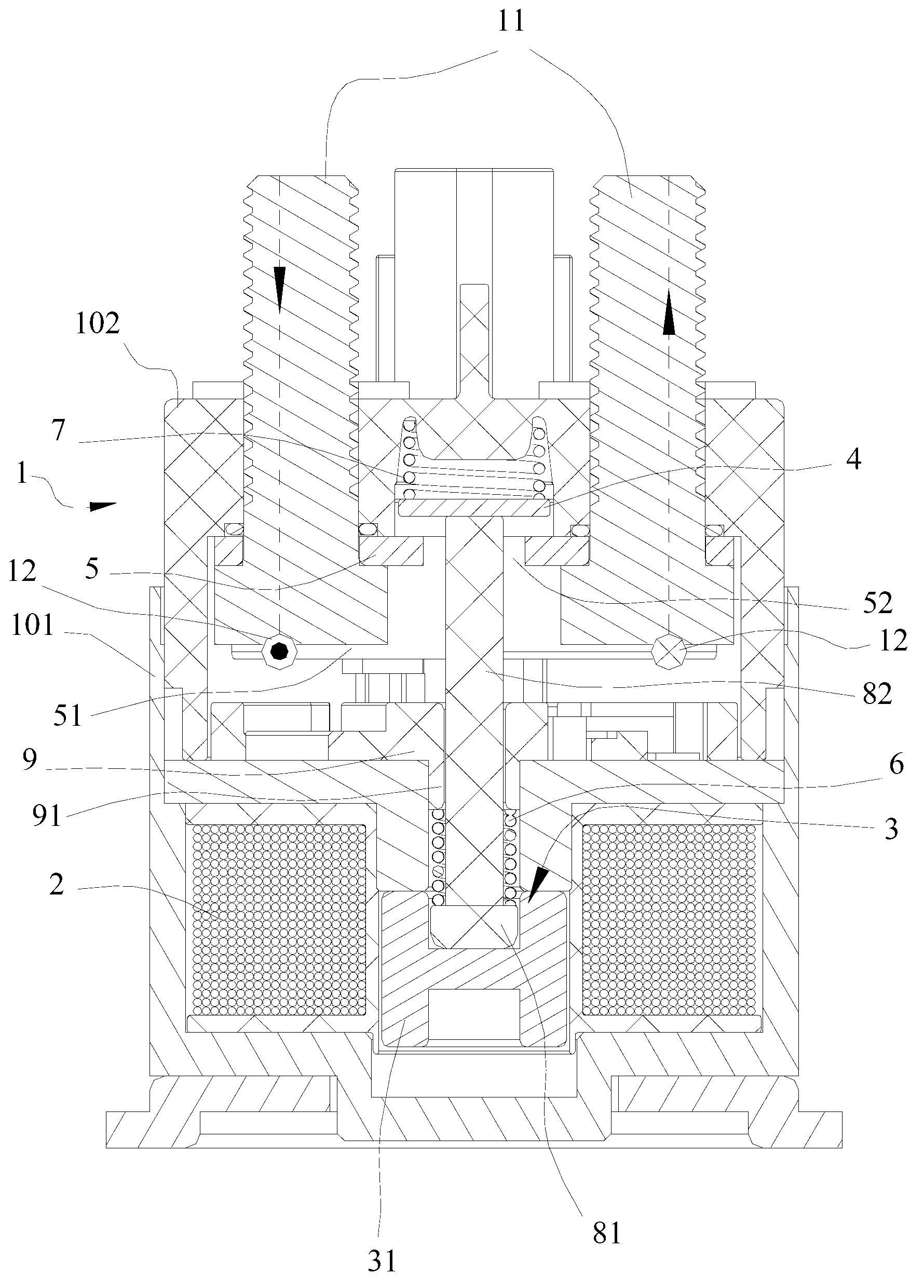

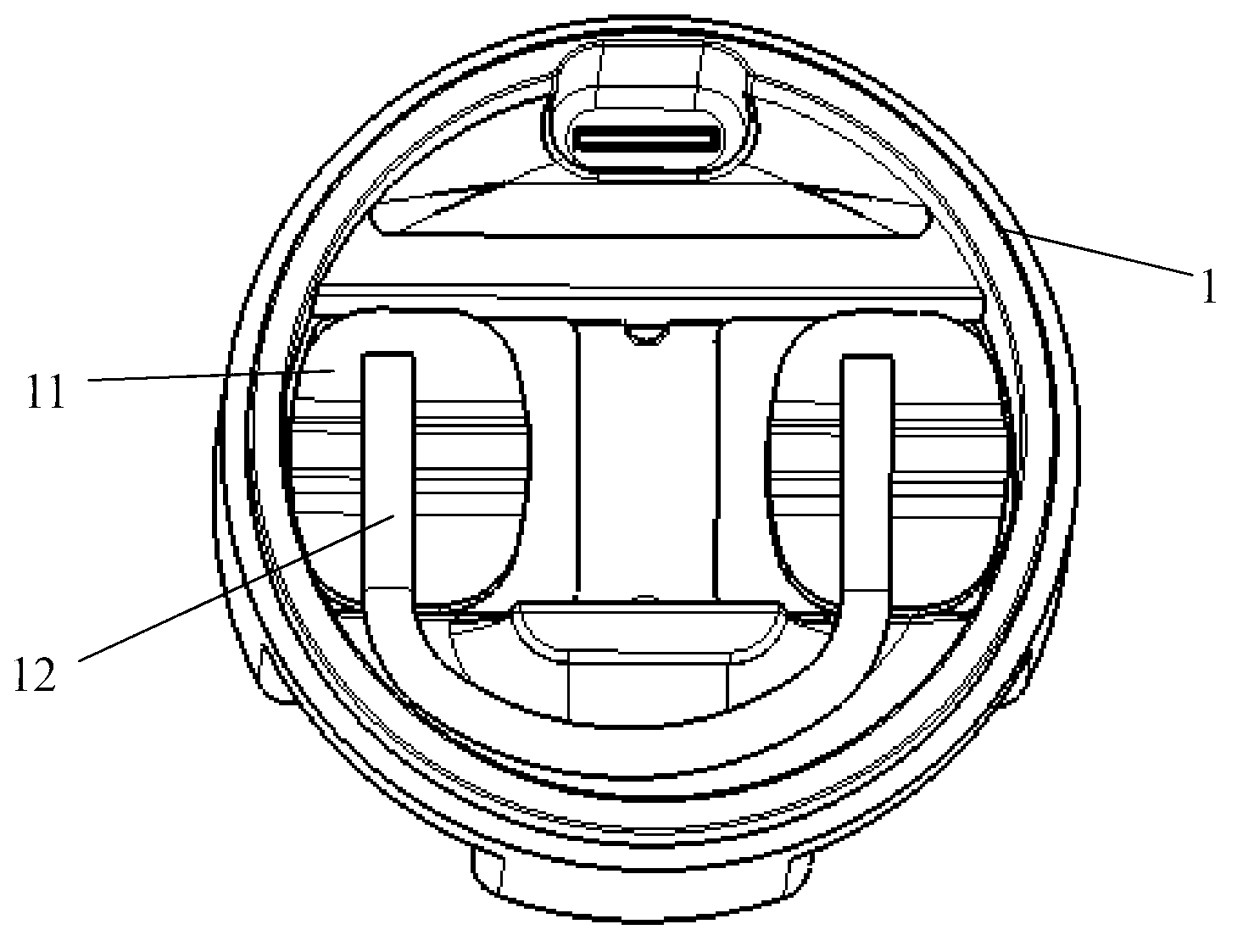

Method for inhibiting peak starting current of start-stop motor, relay and start-stop motor

ActiveCN103061944AImprove life shorteningReduce the starting currentElectric motor startersMachines/enginesElectrical resistance and conductanceCurrent limiting

The invention discloses a method for inhibiting peak starting current of a start-stop motor. The method includes that firstly a relay with a current limiting resistor is added to a main start-stop motor loop comprising a storage battery, an ignition switch, a contact of an electromagnetic switch and the start-stop motor, and two binding posts of the current limiting resistor and the relay are parallelly connected and then connected between the ignition switch and the contact of the electromagnetic switch; and secondly, a power supply of the storage battery supplies power for coils of the relay and the electromagnetic switch respectively. The invention further discloses a relay for achieving the method for inhibiting peak starting current of the start-stop motor and a start-stop motor for implementing the method for inhibiting peak starting current of the start-stop motor. According to the method, the relay and the start-stop motor, the current limiting resistor is cut in or cut out when ignition is performed in the start-stop motor loop, so that overlarge starting current can be inhibited at the moment of starting of the start-stop motor so as to achieve the purpose of prolonging the service life of the start-stop motor.

Owner:GAC COMPONENT CO LTD

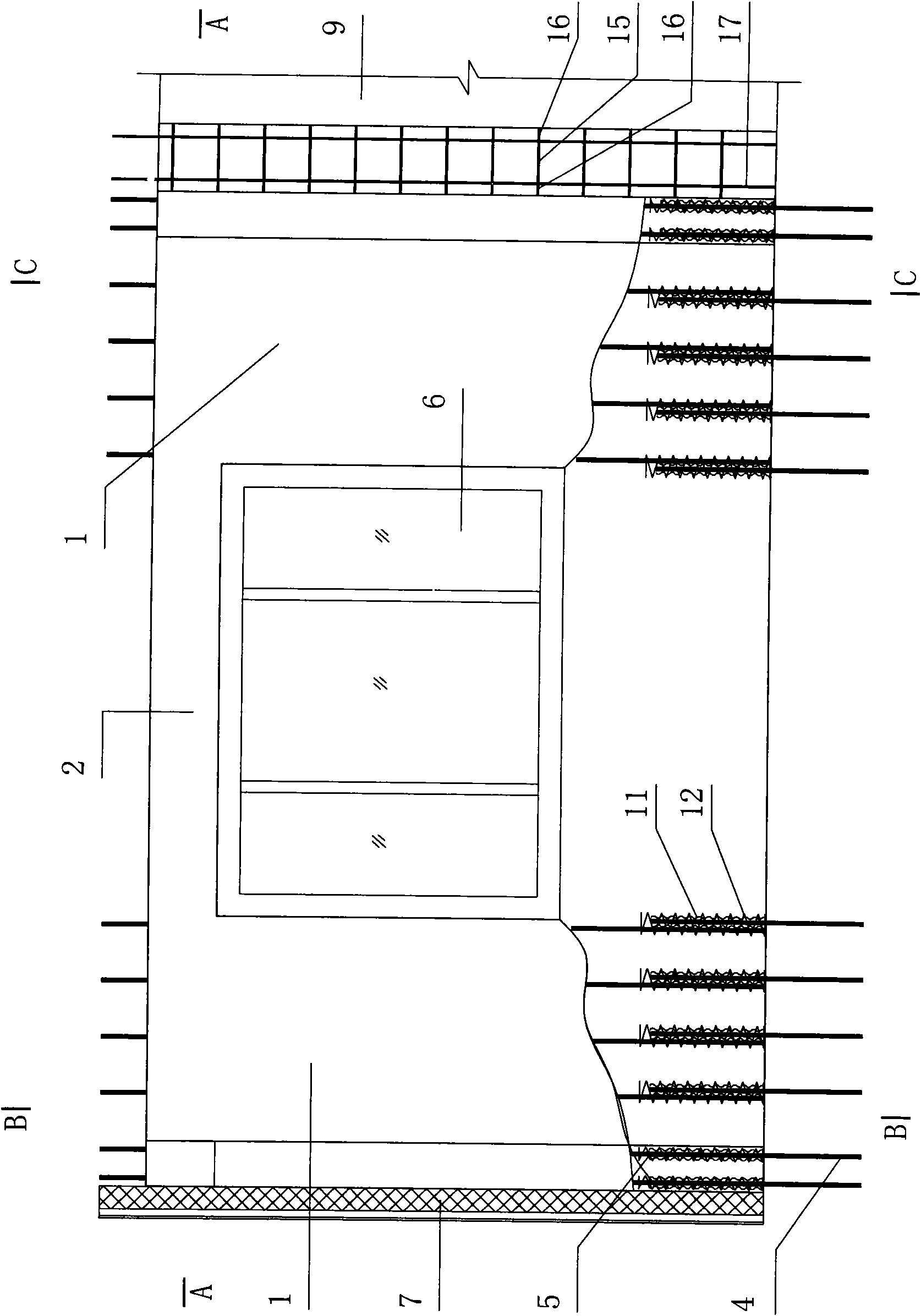

Precast concrete short-limb shear wall provided with door windows and manufacturing method thereof

The invention relates to a precast concrete short-limb shear wall provided with door windows and a manufacturing method thereof. The concrete short-limb shear wall refers to a shock-resistant wall of which the ratio of the wall limb cross section height to the thickness is between 5 and 8, and according to the active code requirement in China, the cross section thickness of a wall body is not less than 200 millimeters, and the stress performance of the structure of the concrete short-limb shear wall is between a specially-shaped column and a common shear wall structure. Because of the good performances in various aspects of construction, structure, construction cost, energy conservation and environmental protection and the like, the structural system becomes the structural form which is most suitable for residential constructions. The precast concrete short-limb shear wall comprises precast concrete wall limbs (1), wherein the wall limbs (1) are connected with connecting beams (2), are provided with door windows (6), and are connected with an external wall heat insulation layer and an architectural surface (7), and the wall limbs are connected with each other by assembling steel bars. The precast concrete short-limb shear wall is applied to industrialized fully-assembled shear walls for residential buildings.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

Flame retardant and heat-insulation foamed concrete and preparation method thereof

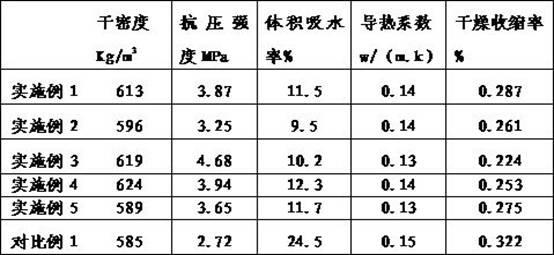

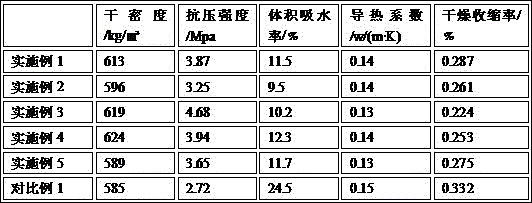

InactiveCN102320858AHigh strengthImprove flame retardant insulation performanceCeramicwareFoam concreteCellulose

The invention belongs to a flame retardant and heat-insulation building material, relates to flame retardant and heat-insulation foamed concrete and a preparation method thereof. In the prior art, the foamed concrete has disadvantages of low strength, large shrinkage, easy cracking due to water absorption. The flame retardant and heat-insulation foamed concrete provided by the present invention comprises the following materials, wherein the materials comprise, by mass, 30-60 parts of cement, 30-70 parts of fly ash, 10-40 parts of mineral powder, 0.05-1.0 parts of a siloxane water reducing agent, 0.02-0.2 parts of a cellulose ether, 0.05-1.0 parts of a silane water-repelling agent, 1-10 parts of anhydrite, 0.06-0.2 parts of polypropylene fibers, 0.1-0.4 parts of a foaming agent and 0.30-0.60 parts of water. The flame retardant and heat-insulation foamed concrete and the preparation method provided by the present invention have the following advantages that: the foamed concrete has characteristics of high strength, low shrinkage and good water repellency; the foamed concrete has excellent heat insulation property, such that different heat insulation requirements of the building can be met; the preparation process is simple; the industrial waste materials such as fly ash, mineral powder and the like are adopted so as to protect the environment.

Owner:杨淑贤

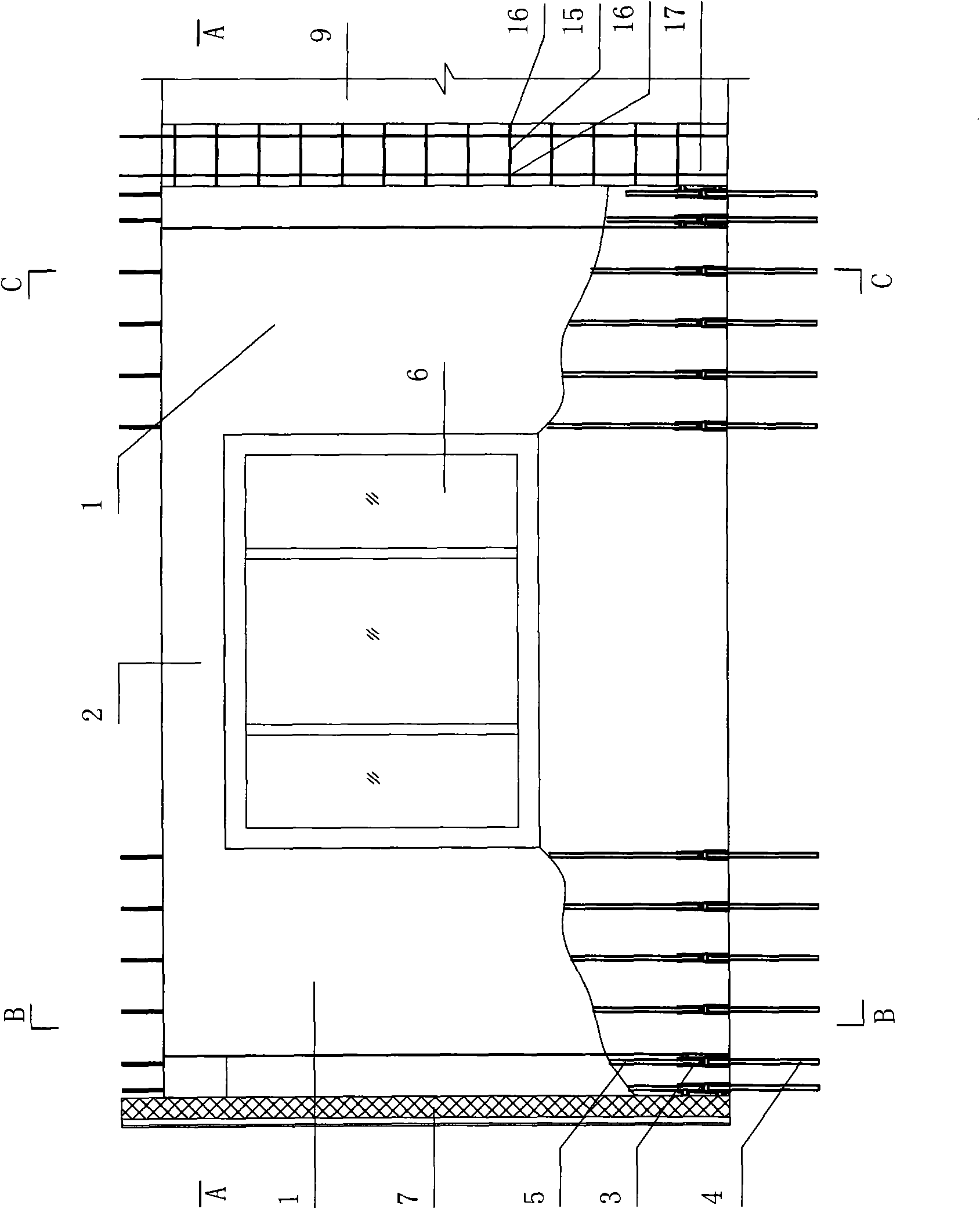

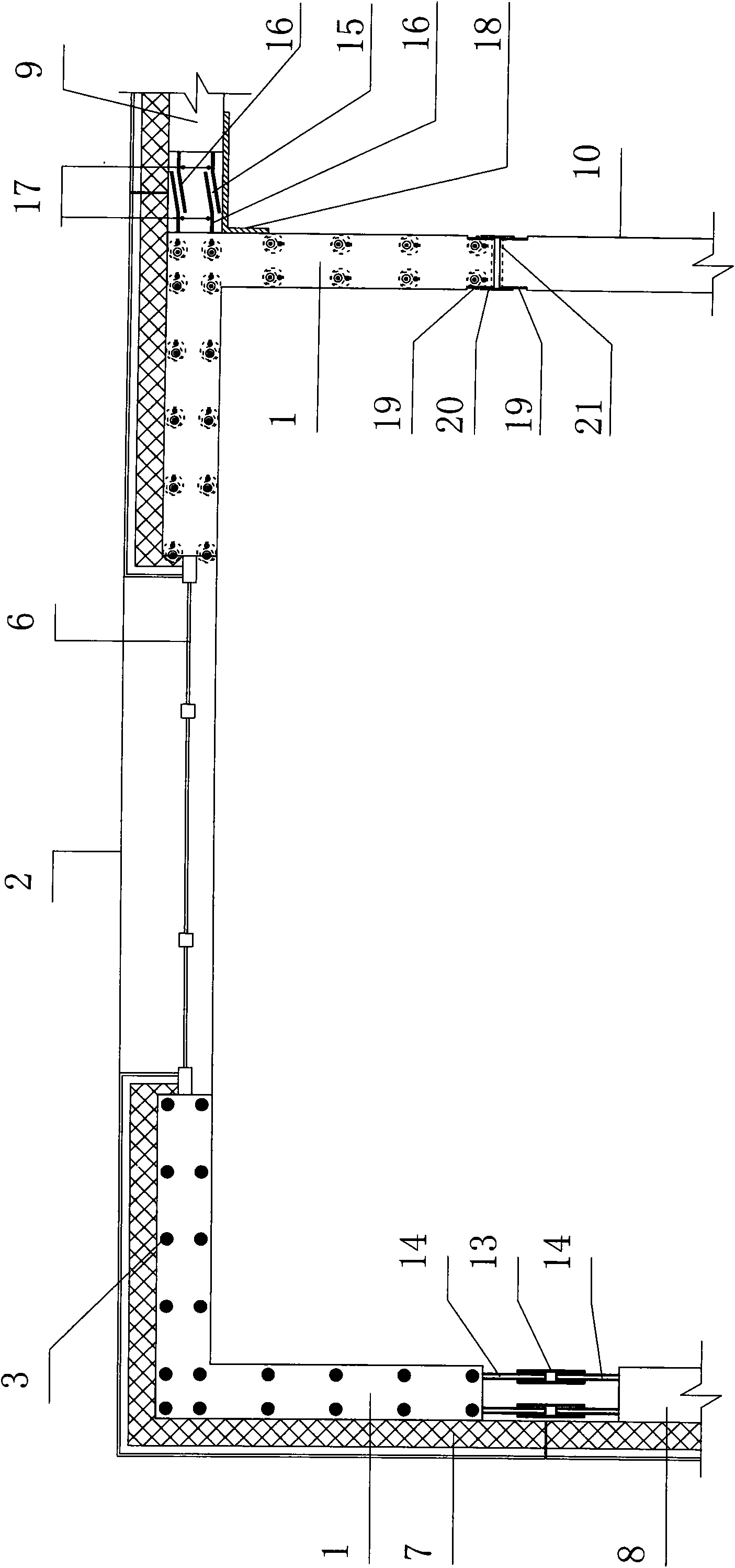

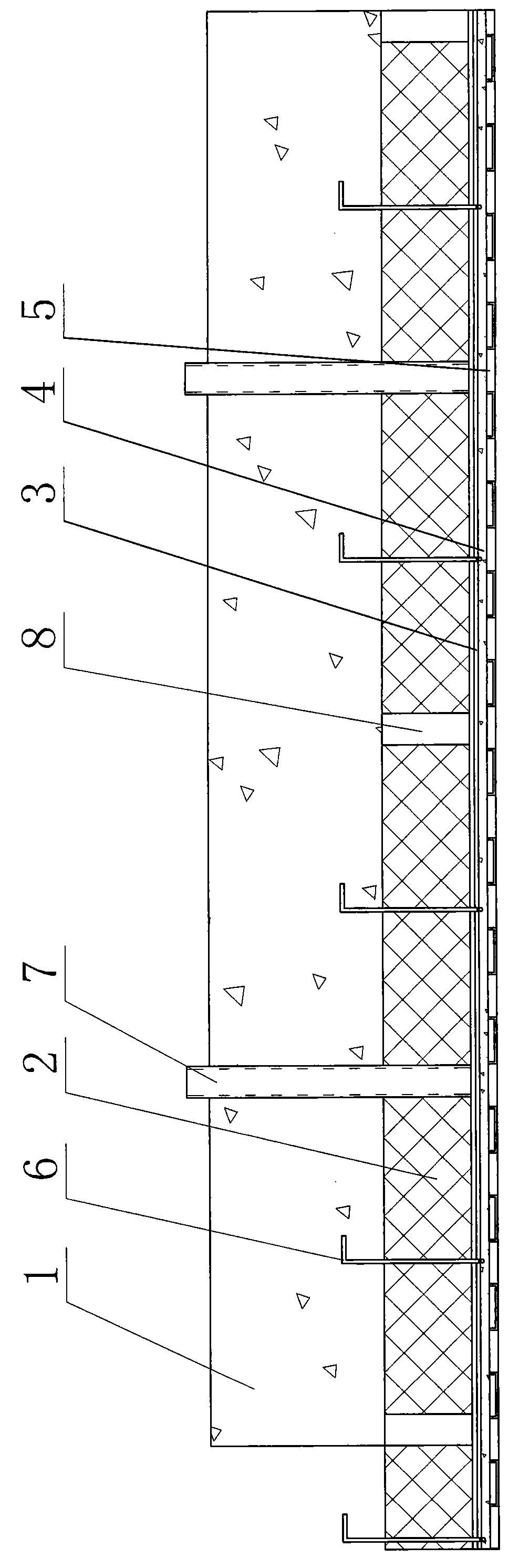

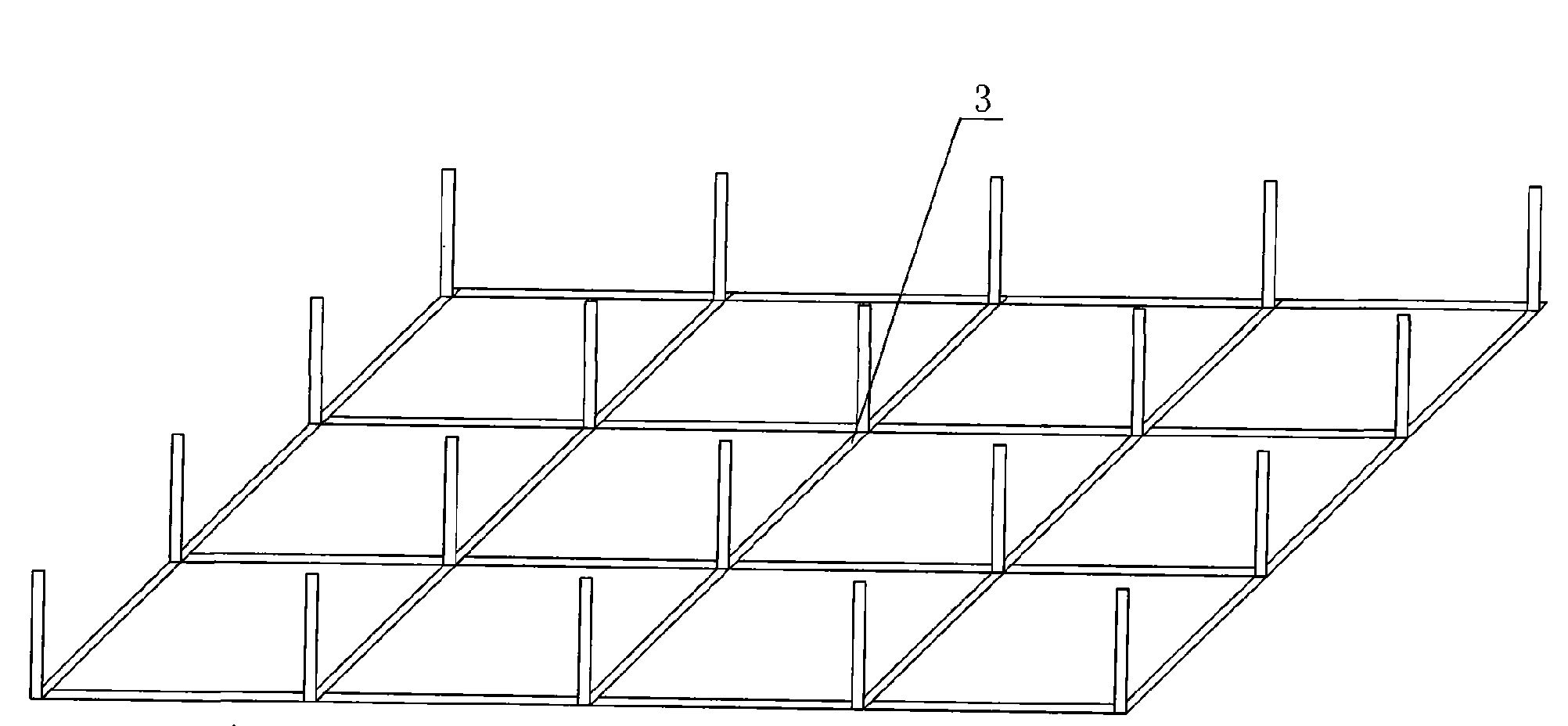

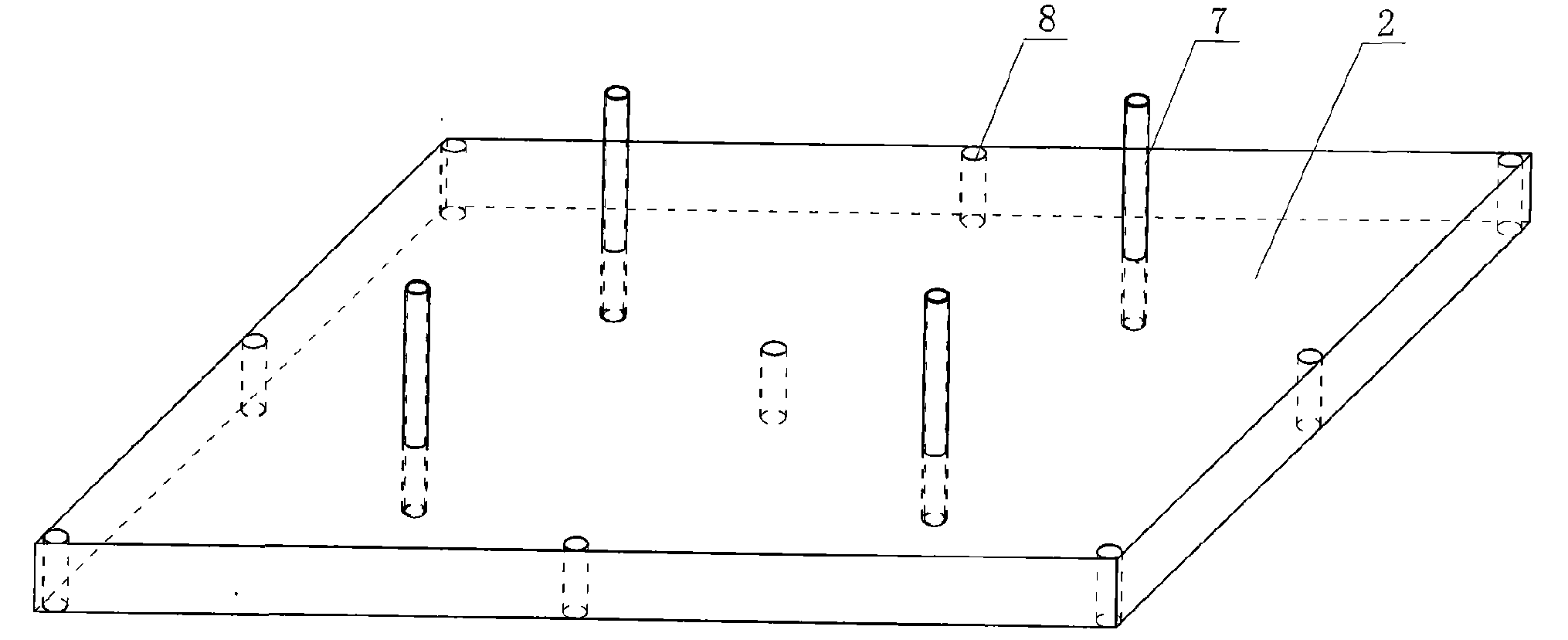

Once formed precast concrete shear wall with heat preserving veneer and production method thereof

InactiveCN101603335AUnified specificationsUniform qualityWallsClimate change adaptationResidenceRebar

The invention relates to a once formed precast concrete shear wall with a heat preserving veneer and a production method thereof. A building structure with an original construction way has higher comprehensive energy consumption and is not beneficial to the environment and energy saving in the construction way. The once formed precast concrete shear wall with a heat preserving veneer comprises a wall body (1) which is connected with an insulating layer (2), a welding reinforcing mesh (3), a sand pulp bonding layer (4) and an architectural surface (5) in sequence, wherein a binding bar is bound with the wall body; the sand pulp bonding layer is connected with a pulp filling pipe (7) passing through the wall body; and the sand pulp bonding layer is provided with an air exit hole (8). The invention is used as a residence industrial all-assembled type construction wall body and a production method thereof.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

Method for preparing mildewproof rubber by using regenerated rubber as basal body

The invention discloses an anti-mildew rubber preparation method with regenerated rubber as a base body, which comprises five processes: raw material ratio, plasticization, mixing, sheet forming and molding, wherein, the ratio of raw materials is: 60 to 80 percent of ethylene propylene diene monomer regenerated rubber, 20 to 40 percent of ethylene propylene diene monomer, 5 to 10 percent of zinc oxide, 0.5 to 1.5 percent of stearic acid, 5 to 35 percent of carbon soot, 5 to 35 percent of light calcium carbonate, 0.5 to 1.5 percent of age inhibitor RD, 0.5 to 1.5 percent of age inhibitor MB, 0.5 to 2.0 percent of sulfur, 0.5 to 2.0 percent of accelerant M, 0.5 to 2.0 percent of accelerant TT, and 0.5 to 1.5 percent of 5, 6-dichloro benzoxazolinone, and the anti-mildew rubber is prepared through processes such as the plasticization, the mixing, the sheet forming, the molding and so on. The anti-mildew rubber has good anti-mildew performance and physical mechanical performance, fully utilizes a renewable resource of waste rubber, and reduces the cost, and contributes to environmental protection and energy conservation.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

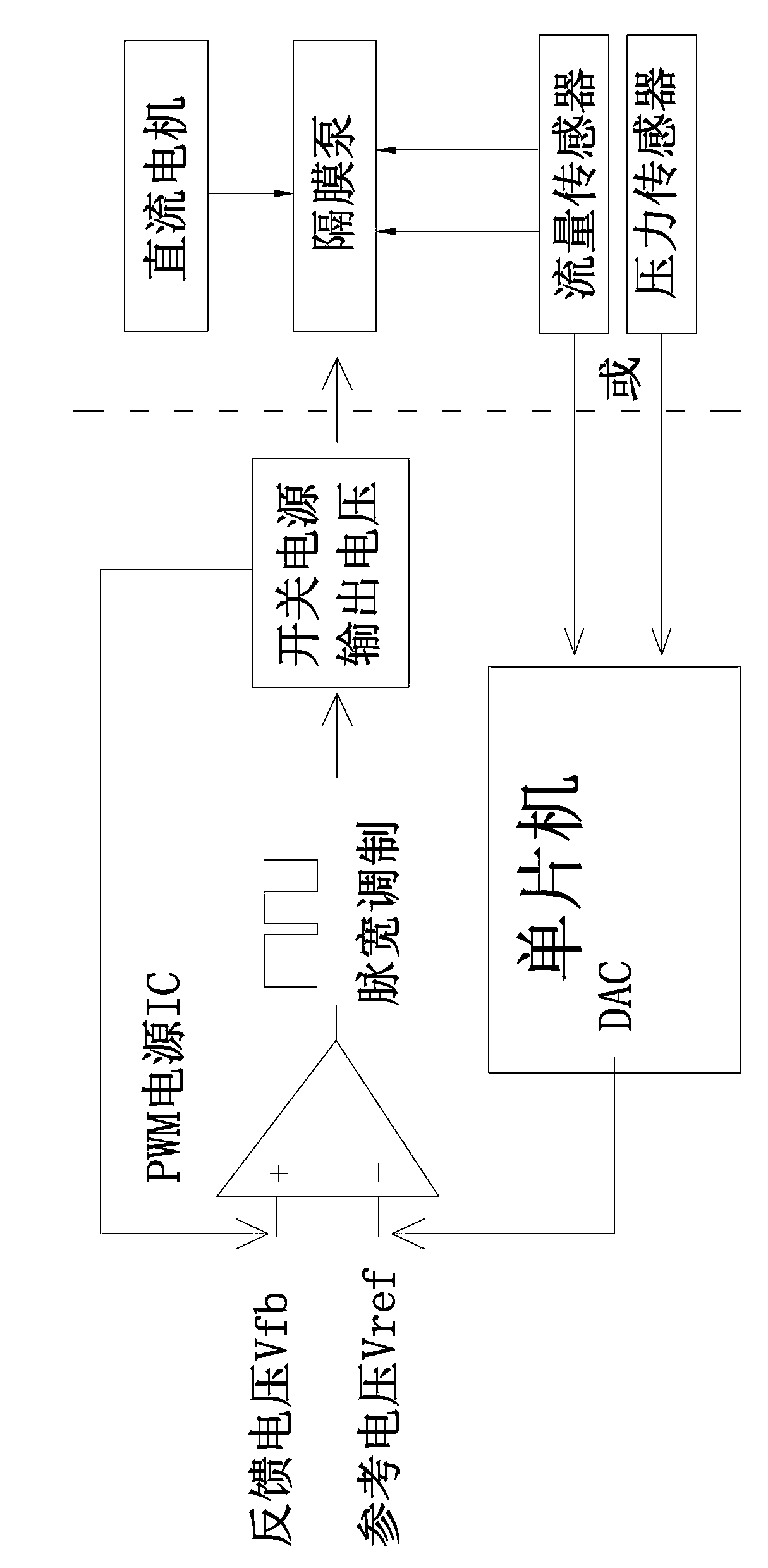

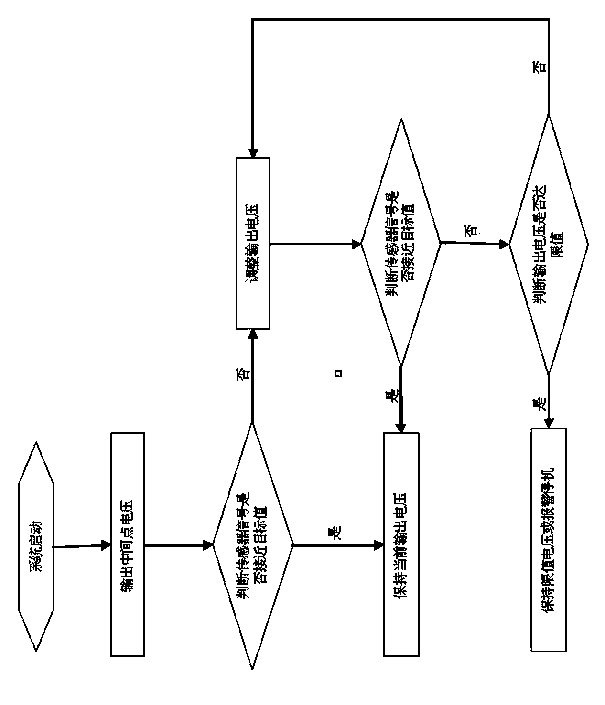

Small-sized diaphragm pump simulation frequency changing system and control method thereof

ActiveCN103629095AAccurate pressureGuaranteed uptimePump controlPositive-displacement liquid enginesMicrocontrollerEngineering

Disclosed are a small-sized diaphragm pump simulation frequency changing system and a control method thereof. The small-sized diaphragm pump simulation frequency changing system comprises a PWM switching power source, the PWM switching power source is connected with a diaphragm pump driven by a direct-current motor and a single-chip microcomputer provided with a DAC conversion circuit, and a flow sensor or a pressure sensor is arranged between the diaphragm pump and the single-chip microcomputer. Compared with a traditional method, the control method is characterized in that a multi-voltage-output control circuit is used, meanwhile, the pressure sensor or the flow sensor are additionally arranged behind the pump for monitoring the force output state of the pump, similar frequency changing effects are realized through cooperative control of the pressure sensor or the flow sensor and output voltages of the circuit, and therefore the work target of realizing constant voltages or constant currents is achieved. By means of the small-sized diaphragm pump simulation frequency changing system and the control method of the small-sized diaphragm pump simulation frequency changing system, power consumption of the water pump can be automatically adjusted to be at the best level, ultrapure water indexes can be stabilized, the water taking flow speed is kept to be constant, the system yield is kept to be stable and environmental friendliness and energy conservation are realized.

Owner:厦门锐思捷水纯化技术有限公司

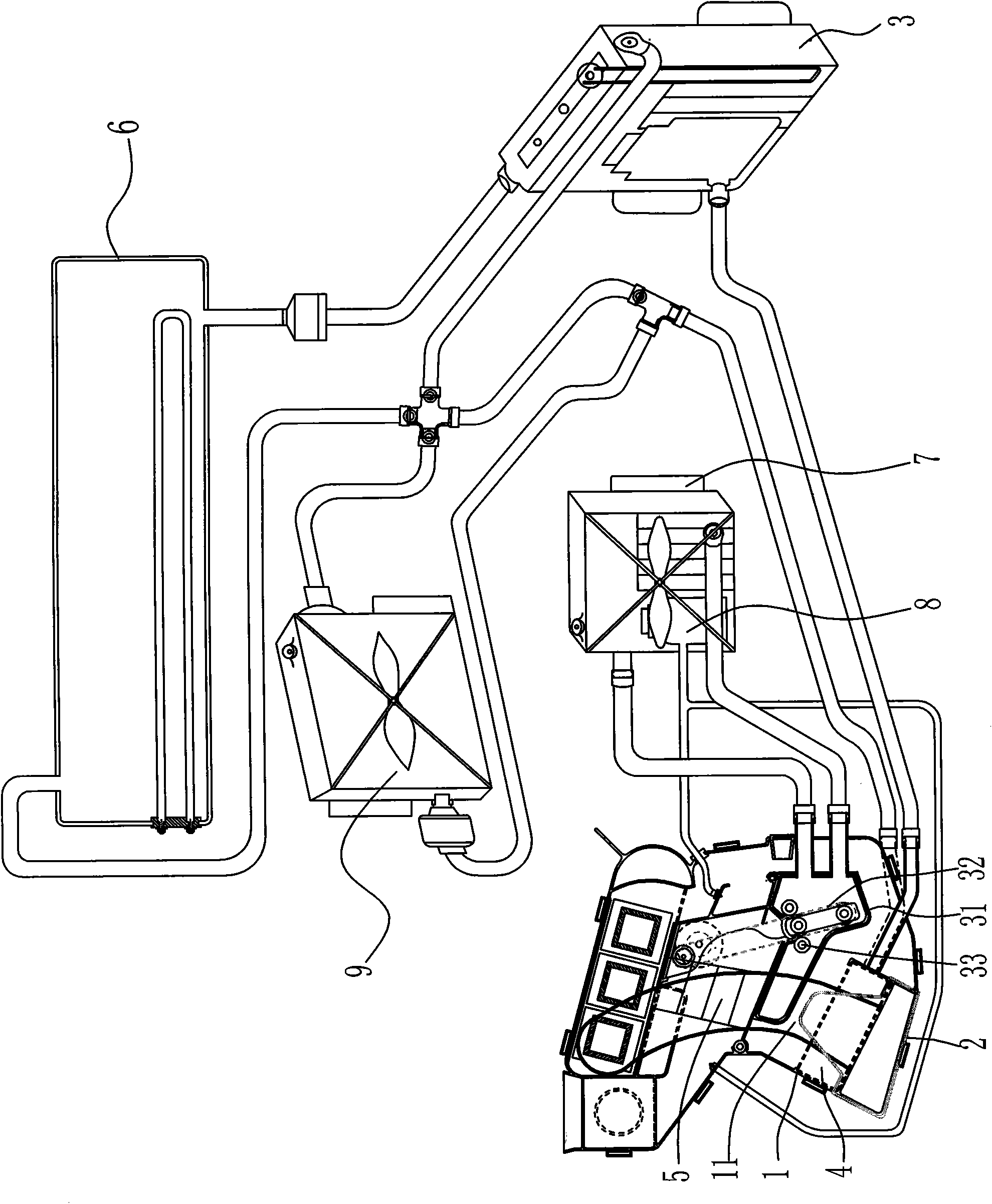

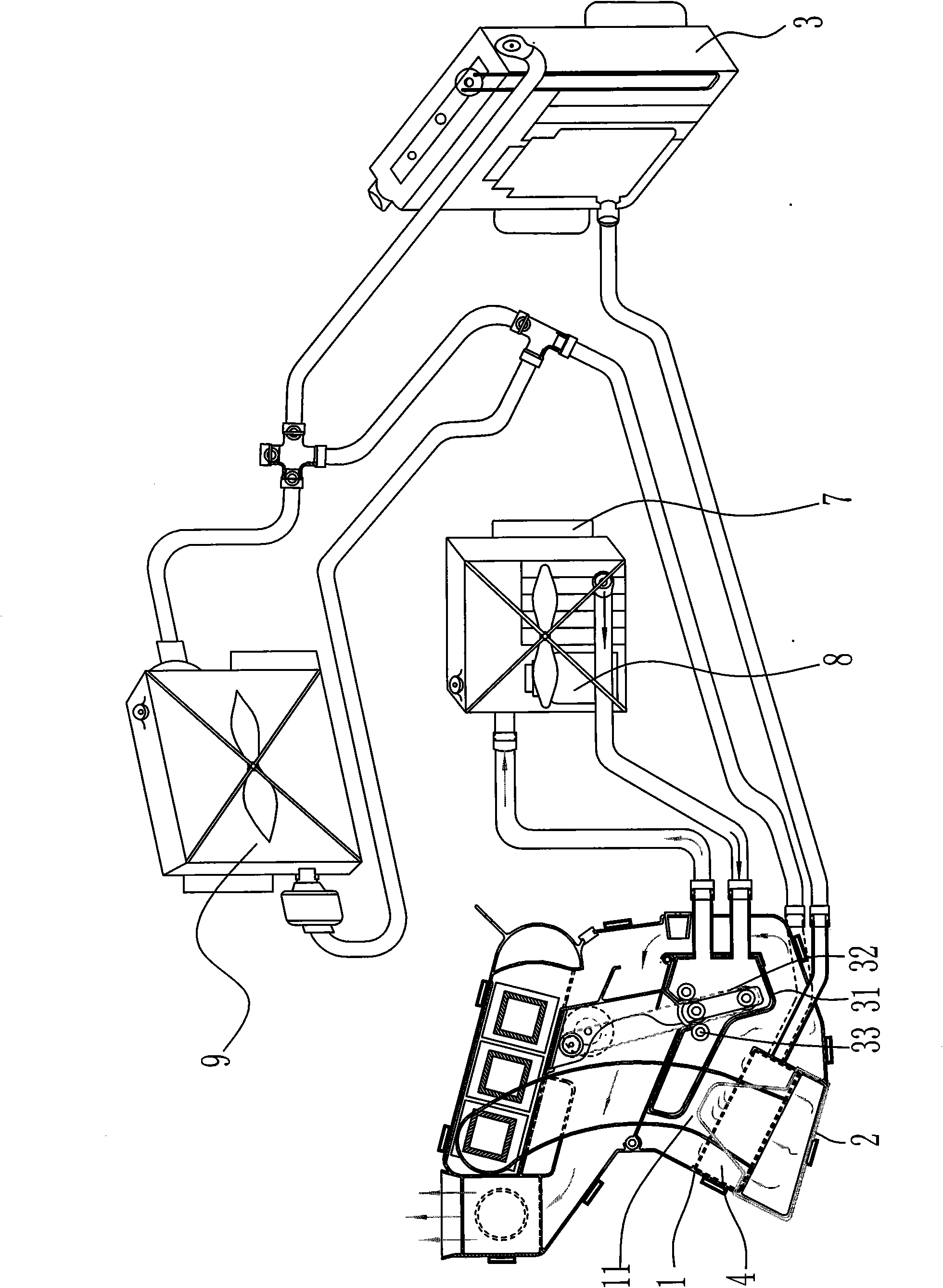

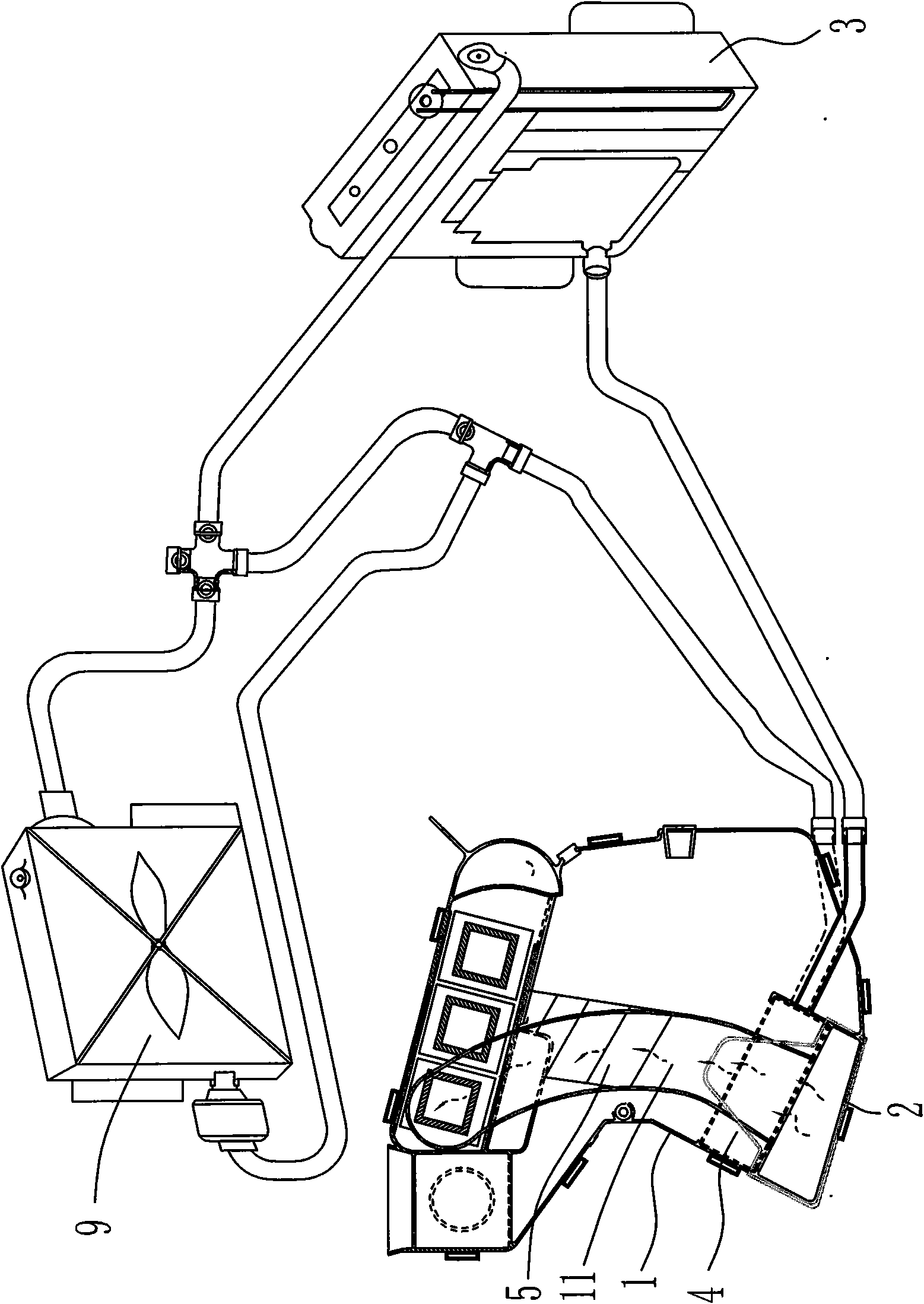

Heating and cooling system used in carriage of electric automobile

InactiveCN101832609AImprove cooling effectFresh airEnergy recovery in ventilation and heatingLighting and heating apparatusCold airCooling effect

The invention discloses a heating and cooling system in a carriage of an electric automobile, comprising a water way assembly, a shell with an air passage, and an air blower, wherein the water way assembly comprises a main water tank for heating or cooling and a water circulating tank; the main water tank is communicated with the water circulating tank so as to heat or cool return water of the water circulating tank; the water circulating tank is installed in the shell; and the air blower blows facing to the water circulating tank so as to introduce hot air or cold air into the carriage of the automobile through the air passage. When the heating and cooling system is used, different heating and cooling modes are selected, therefore, the heating and cooling system can respectively independently or comprehensively and simultaneously work without mutual influence, can effectively obtain heating and cooling effects of various modes, needs compressors or any chemical refrigerant and special lubricating oil no more, purifies the air, has simple use mode and long service life, is more beneficial to environment protection and energy saving, is suitable to industrialized production, and is an environment-friendly air conditioner which is not only suitable for use on electric automobiles, but also suitable for use on other aspects.

Owner:湖南丰日福悦电动车股份有限公司

Steel-slag inflaming-retarding heat-preservation foam concrete and preparing method thereof

InactiveCN106220067AReduce water consumptionReduce volumeSolid waste managementCeramicwareIndustrial wasteScrap

The invention discloses a steel-slag inflaming-retarding heat-preservation foam concrete. The steel-slag inflaming-retarding heat-preservation foam concrete is prepared from, by mass, 30-60 parts of cement, 30-70 parts of steel-slag water washing dust sludge, 10-40 parts of steel slag composite powder, 0.05-1.0 part of water reducing agent, 0.02-0.2 part of thickening agent, 0.05-1.0 part of water repellent, 1-10 parts of sintered desulfurized ash, 0.06-0.2 part of anti-cracking agent, 0.1-0.4 part of foaming agent and 0.30-0.60 part of water. The steel-slag inflaming-retarding heat-preservation foam concrete has the advantages that the preparing technology is simple, the foam concrete is high in strength, low in shrinkage, good in hydrophobicity, excellent in heat insulation performance and capable of meeting different heat preserving requirements of buildings, industrial waste such as the steel-slag water washing dust sludge, the steel slag composite powder and the sintered desulfurized ash is sufficiently used, and the excellent waste-utilizing and energy-saving environment-protection effect and good economic benefits are achieved.

Owner:广西玉林市绿盛科贸有限责任公司

Compound thermal-insulation material and preparation method thereof

InactiveCN101648799AImprove performanceImprove crack resistanceSolid waste managementClimate change adaptationFrostCrack resistance

The invention relates to a compound thermal-insulation material and a preparation method thereof, belonging to the field of building materials. The compound thermal- insulation material consists of rubber powder and EPS granules. A rubber powder EPS granule compound thermal-insulation material is used in the thermal-insulation systems of external walls, wherein the external thermal-insulation system is one of thermal-insulation systems listed in JCJ144-2004 Technical Specification for External Thermal Insulation on Walls. The technical system consists of an interface agent, a rubber powder EPSgranule thermal-insulation sizing agent thermal-insulation layer, a crack-resistance mortar thin plaster (alkali proof gridding cloth is paved in the middle) and a finishing coat. The heat conductivity of the rubber powder EPS granule compound thermal-insulation material is smaller than or equal to 0.06w / (m.k), the dry density is 180kg / m<3>-250kg / m<3>, and the tensile strength is higher than or equal to 0.10MPa. The water retention, the adhesion, the restricted dilatability, the water resistance, the resistance against frost, the heat preservation and the like of the product are greatly improved; meanwhile, the product makes better use of waste plastic foam, thereby being beneficial to protecting environment, recycling waste and eliminating pollution.

Owner:河南省绿韵建材有限公司

Gasoline additive with functions of explosion prevention and fuel saving

ActiveCN104073304AImprove performanceBurn completelyLiquid carbonaceous fuelsGlycol synthesisCo carbon monoxide

The invention belongs to the technical field of gasoline additives, and particularly to a gasoline additive with the functions of explosion prevention and fuel saving. The gasoline additive is characterized by being prepared from the following raw materials in parts by weight: 30-50 parts of methyl tertiary butyl ether, 6-8 parts of dodeyl methacrylate, 6-10 parts of methylcyclopentadienyl manganese tricarbonyl, 3-5 parts of toluene, 5-8 parts of potassium oleate, 5-8 parts of magnesium laurate, 5-8 parts of naphthenic acid cerium, 6-10 parts of butanone, 6-10 parts of ethyl acetate, 10-20 parts of ethylene glycol monobutyl ether, 6-10 parts of triethylamine, 6-10 parts of isopropyl alcohol, 3-5 parts of ortho-xylene, 15-25 parts of m-toluic acid, 15-25 parts of methanol, 5-10 parts of trichloroacetic acid and 5-10 parts of trichloro ethane. The gasoline additive mainly has the benefits as follows: the anti-explosion property of a vehicle is more excellent, the gasoline is combusted more completely, the discharge capacity of carbon monoxide and hydrocarbon is lower, the carbon deposit is reduced, and the fuel is saved.

Owner:SHANGHAI DELIAN CHEM

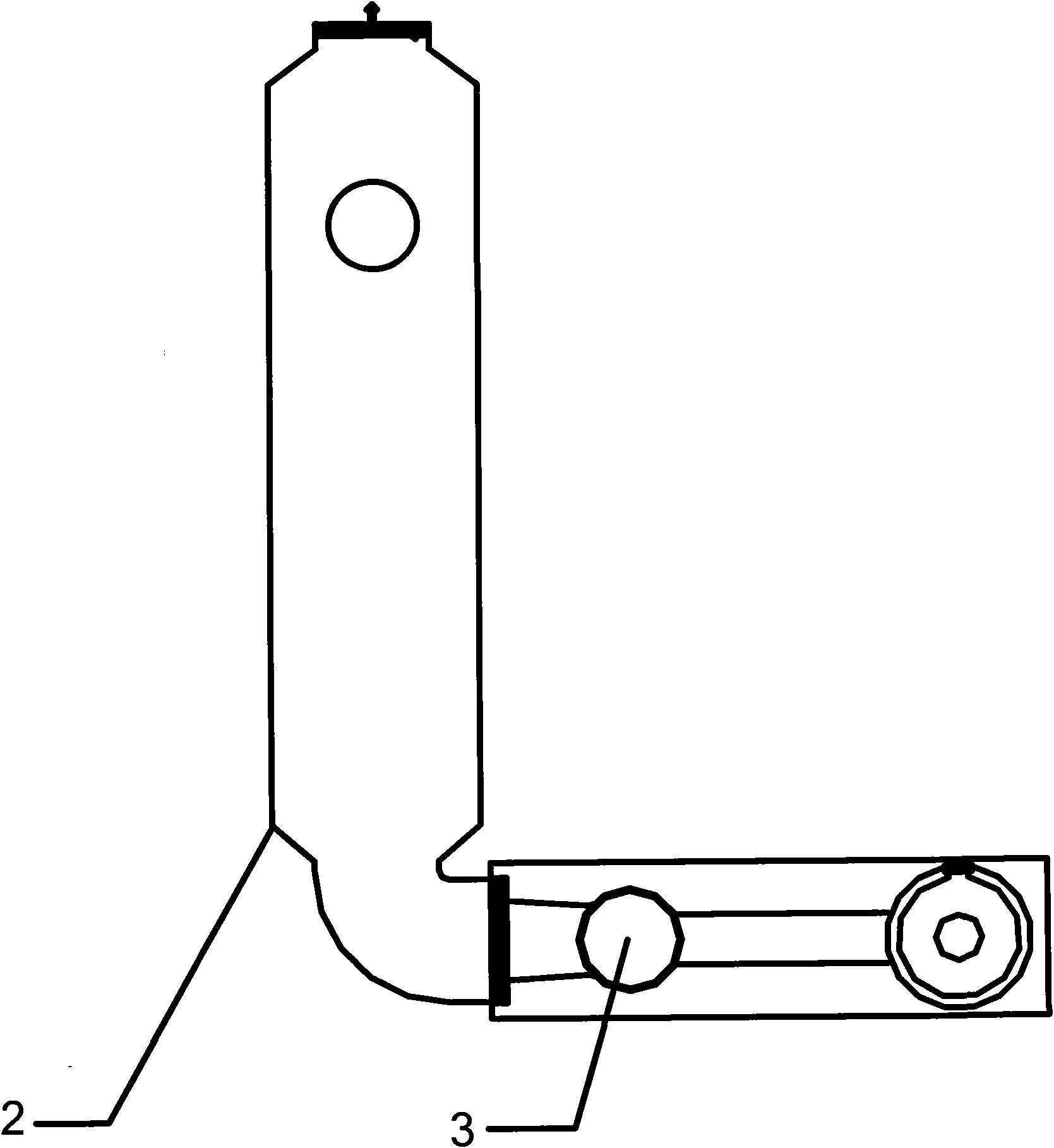

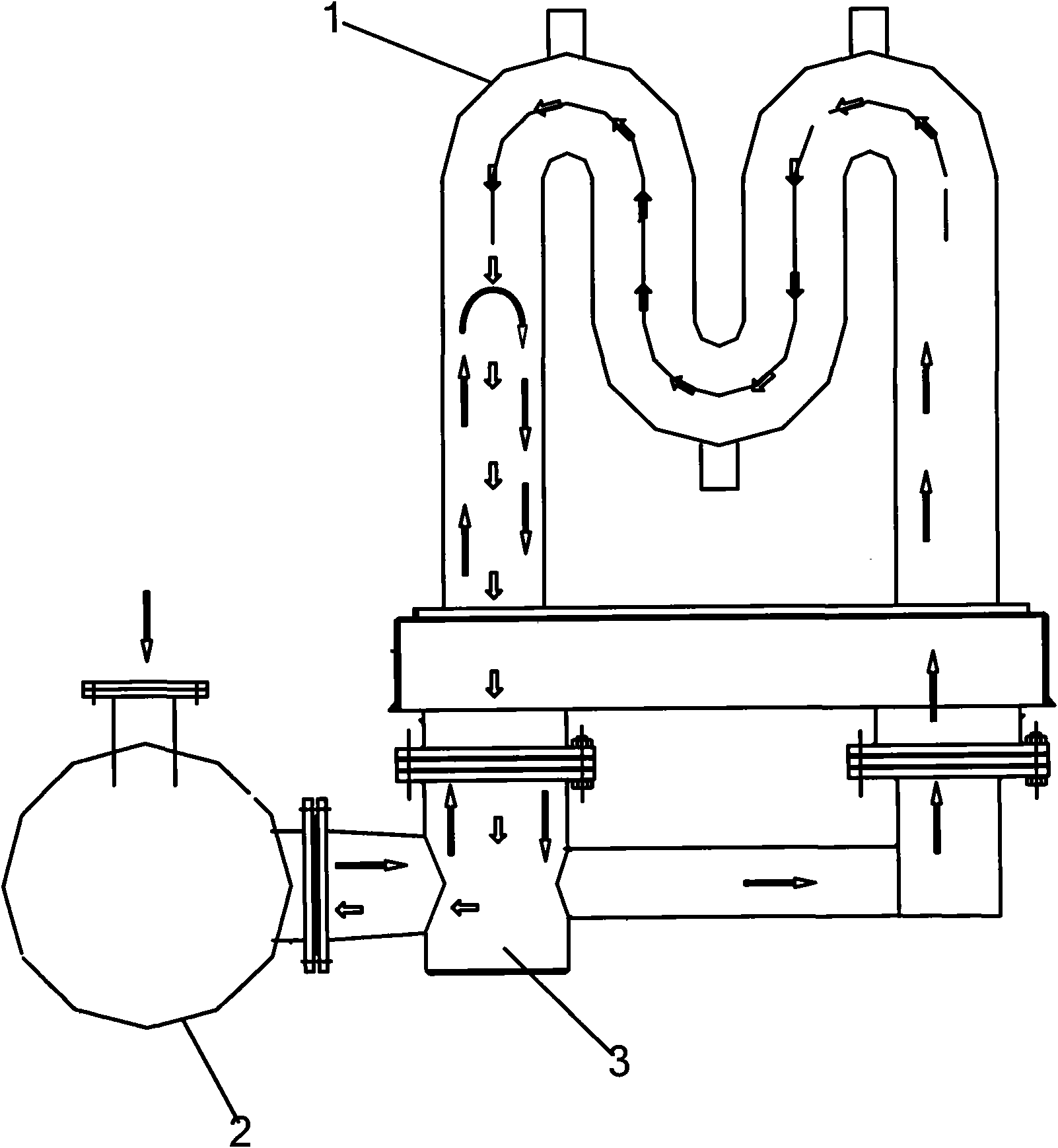

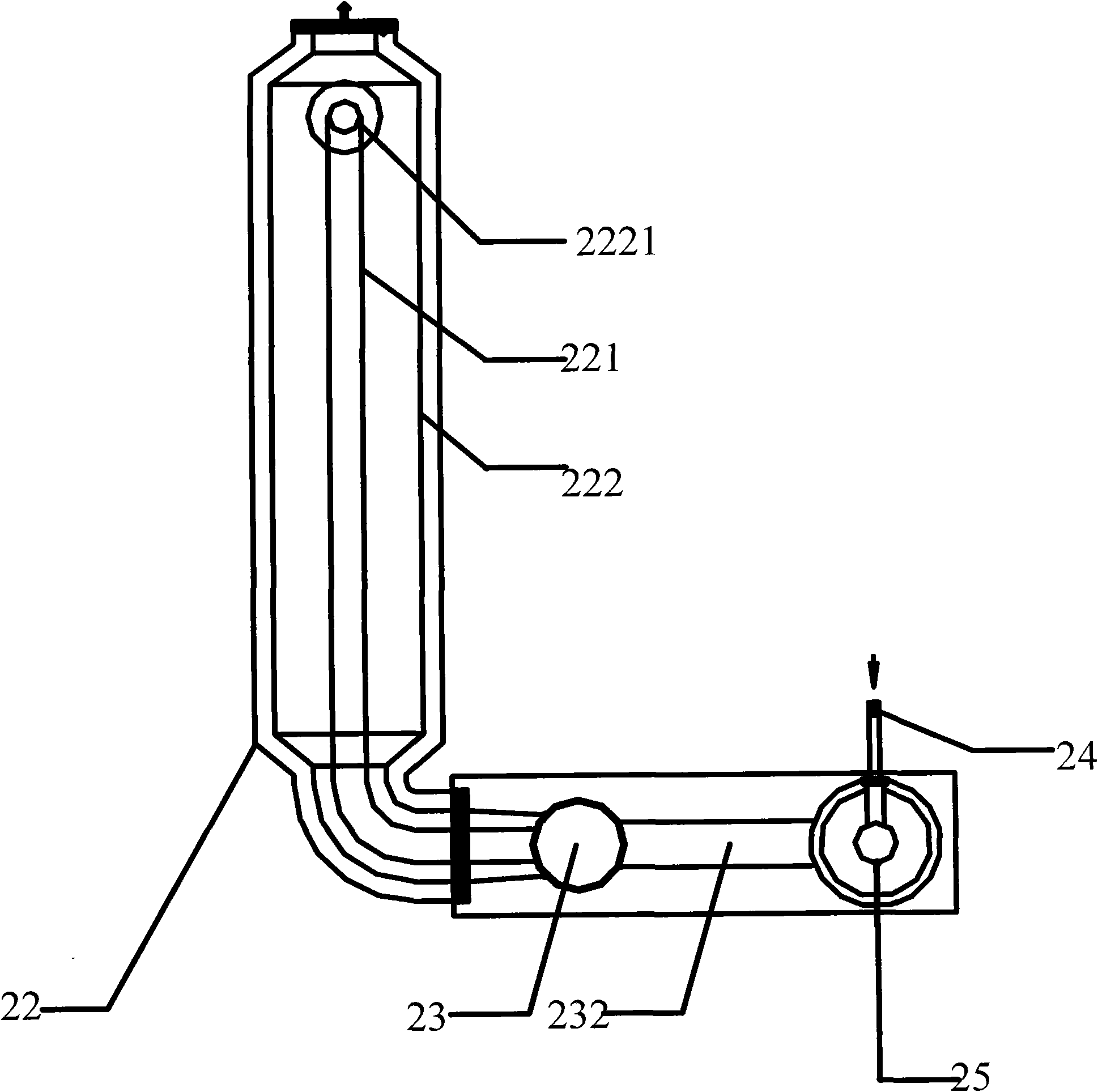

Energy-saving radiant tube component

InactiveCN101943405AIncrease temperatureRaise the combustion temperatureIndirect carbon-dioxide mitigationGaseous fuel burnerCombustionFlue gas

The invention provides an energy-saving radiant tube component which is used for solving the problems of high temperature of flue gas exhausted from a radiant tube and low utilization rate of energy in the prior art. The energy-saving radiant tube component comprises the radiant tube, as well as a primary heat exchanger and a secondary heat exchanger, wherein the primary heater exchanger is used for receiving and exhausting the flue gas led-in by the secondary heat exchanger, leading-in air, utilizing the energy of the flue gas to carry out first preheating on the air and leading-out the air after the first preheating to the secondary heat exchanger, wherein the flue gas is exhausted by the radiant tube; and the secondary heat exchanger is used for leading-in the flue gas into the primary heat exchanger, receiving the air after the first preheating, utilizing heat of the flue gas to carry out second preheating on the air after the first preheating, and leading-out the air after the second preheating to a burner combustion-supporting air inlet of the radiant tube. The technical scheme can reduce the temperature of exhaust smoke and improve the utilization rate of the energy and the heating efficiency of the radiant tube.

Owner:BEIJING JJRS TECH DEV

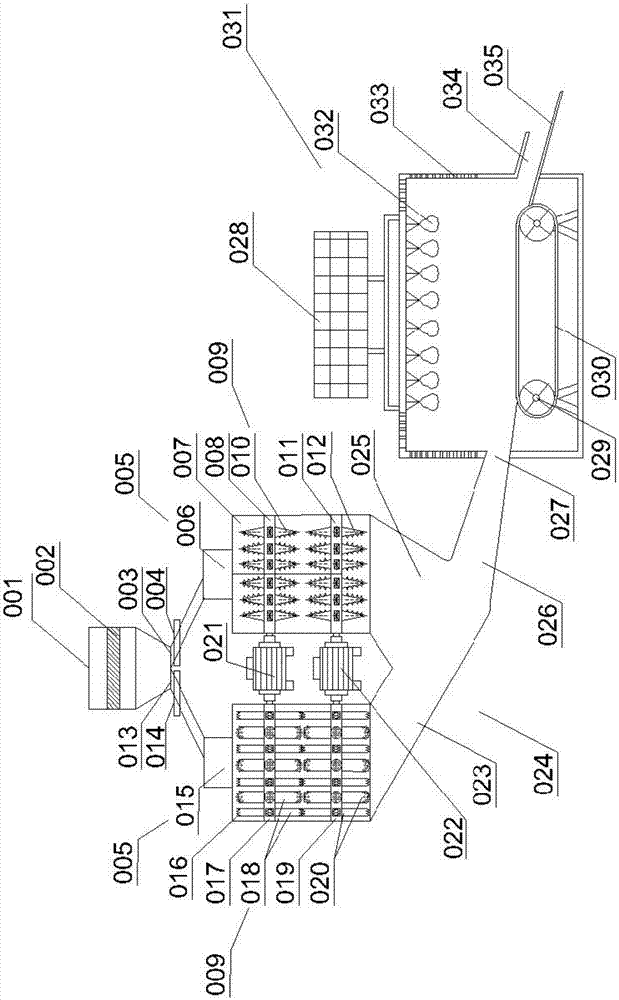

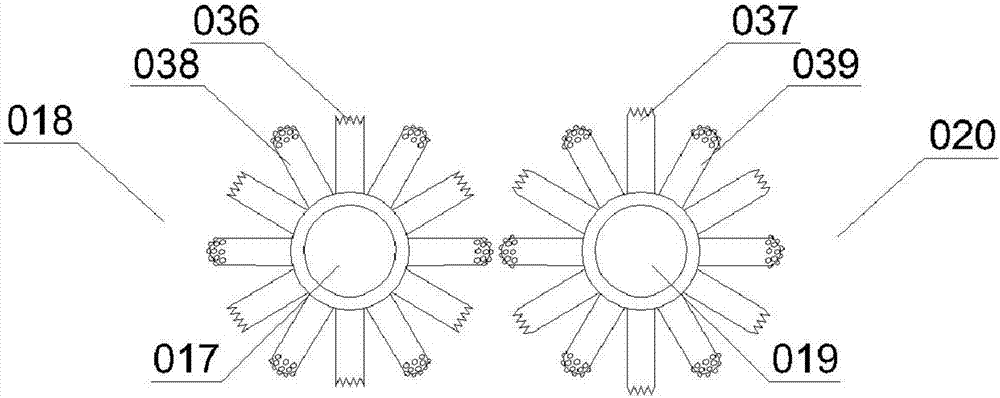

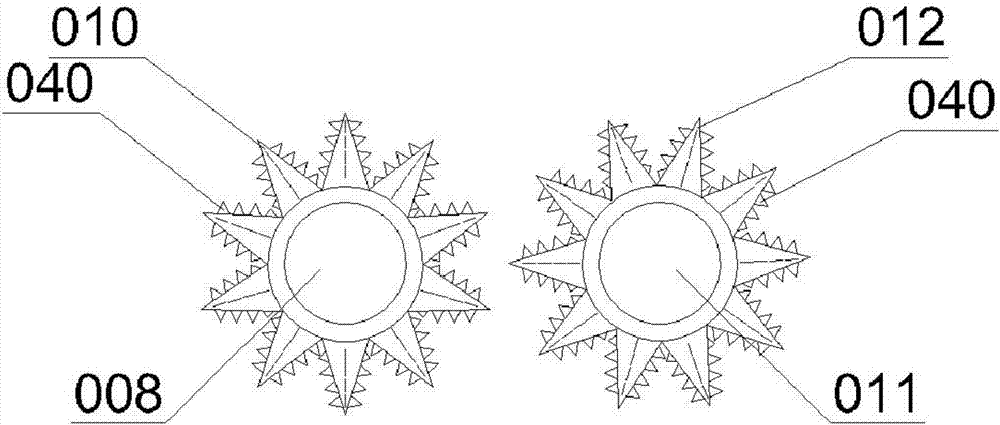

Efficient multistage crushing solid waste treating device

InactiveCN107497576AImprove efficiencyImprove crushing efficiencyDrying solid materials with heatDrying machines with progressive movementsWaste treatment

The invention discloses a high-efficiency multi-stage crushing solid waste treatment device, which relates to the field of solid waste treatment equipment. The invention includes a feeding mechanism, a stirring mechanism, a crushing mechanism, a transportation pipeline and a drying mechanism connected in series in sequence. Set a layer of screen, the bottom of the feeding mechanism is provided with a discharge port A and a discharge port B, the discharge port A is connected in series with the stirring device A and the crushing mechanism A, and the discharge port B is connected in series with the stirring device B And the crushing mechanism B, between the crushing mechanism A and the crushing mechanism B, a double-shaft motor I and a double-shaft motor II that provide power for the crushing mechanism are arranged, and the bottoms of the crushing mechanism A and the crushing mechanism B are connected to the drying mechanism through a transportation pipeline . The invention adopts the combination of multi-stage crushing and processing mechanisms, and sets different types of crushing cutter combinations in the multi-stage crushing mechanism, which improves the crushing efficiency of solid waste, saves energy and protects the environment, and saves costs for subsequent processing.

Owner:弘毅天承知识产权股份有限公司

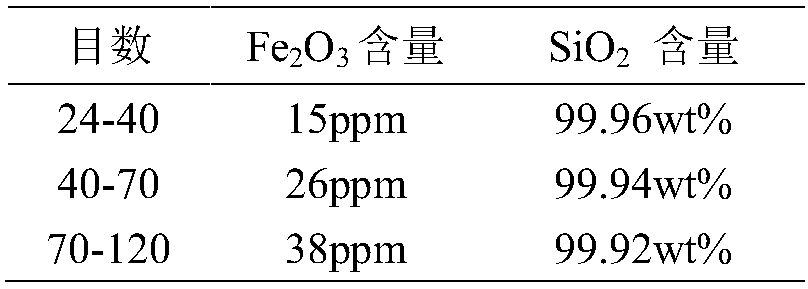

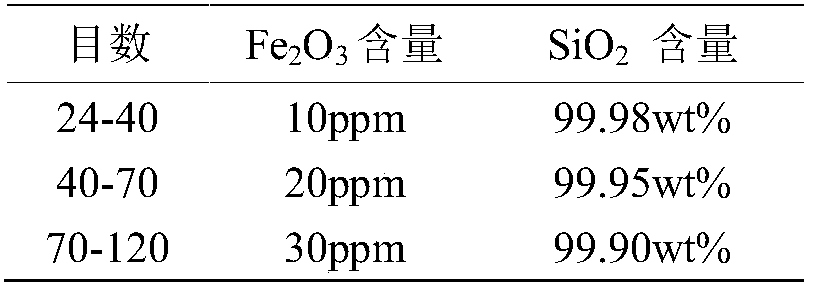

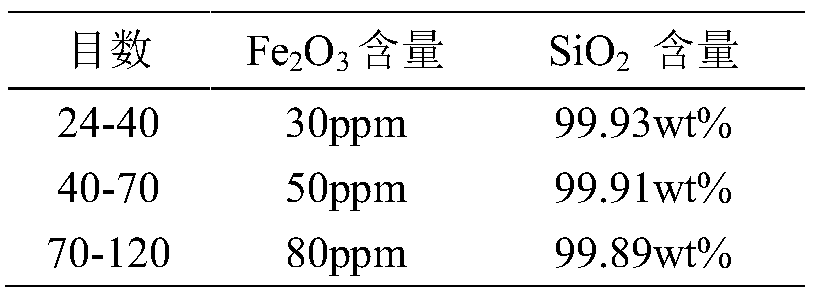

Method of producing high-purity quartz sand without producing quartz tailings

The invention provides a method of producing high-purity quartz sand without producing quartz tailings. The method includes: washing a raw ore with water, crushing, chemically washing, performing color sorting, calcining, carrying out water quenching, drying by airing or baking, performing color sorting, making sand, screening, magnetically separating, performing color sorting, and packaging finished products; magnetically separating screen underflow, carrying out ball milling to obtain powder, screening, and packaging finished products. No tailings are produced in the whole production process; water is greatly saved; product quality is improved; the greatest advantage is that no tailing waste is produced in the production method; wastewater pollution and dust pollution are effectively solved; the method is an energy-efficient environment-friendly production technique.

Owner:HUANGGANG NORMAL UNIV +1

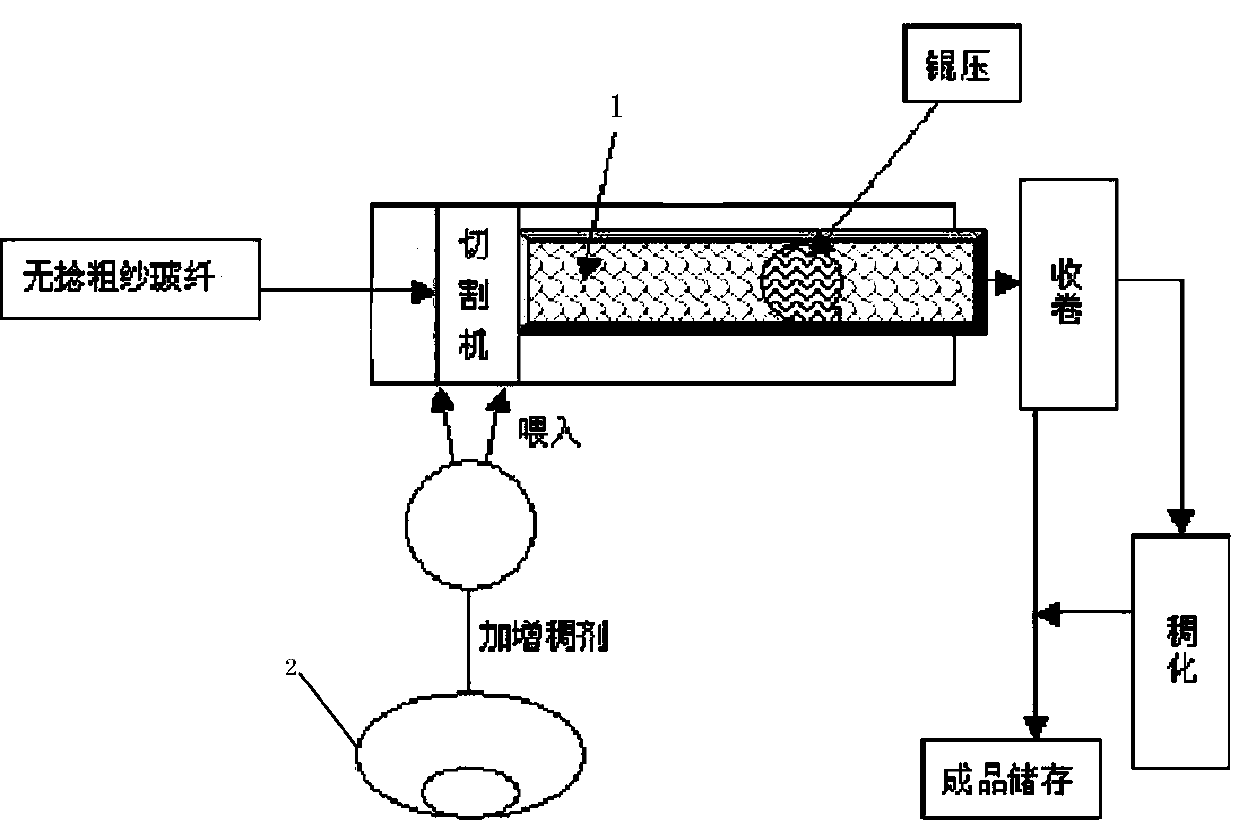

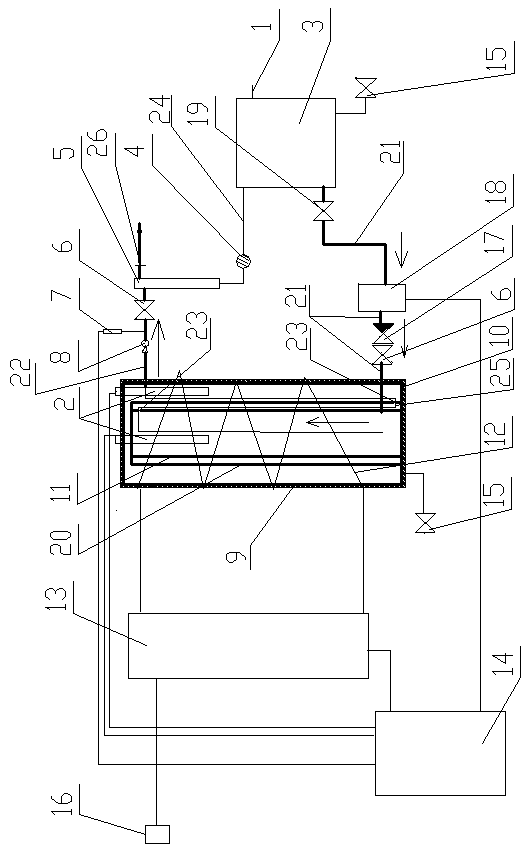

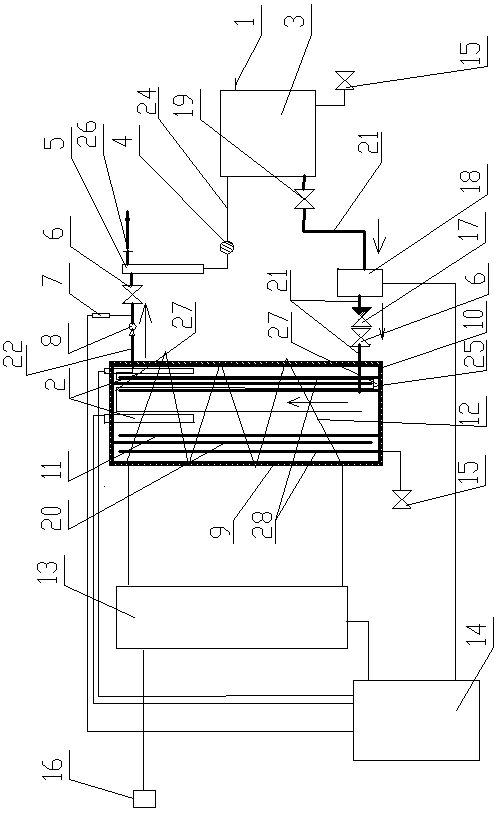

Sheet-shaped mould plastic for manufacturing inspection well lid and preparation method for sheet-shaped mould plastic

The invention firstly provides an environment-friendly and low-cost sheet-shaped mould plastic for manufacturing an inspection well lid. A middle core material of the sheet-shaped mould plastic consists of glass fiber cloth which is soaked with resin paste, wherein the content of glass fibers is 20-40 parts, and the resin paste comprises the following materials in parts by weight: 19-23 parts of unsaturated resin, 6-8 parts of a low shrinkage agent, 1.4-1.6 parts of styrene, 0.5-1.5 parts of a curing agent, 1.5-1.7 parts of zinc stearate, 0.01-0.03 part of benzoquinone, 0.2-0.3 part of pigment paste, and 40-50 parts of ground calcium carbonate of 800-1000 meshes. The invention further provides a method for preparing the sheet-shaped membrane plastic. The sheet-shaped mould plastic provided by the invention adopts base raw materials, and further adopts waste ground calcium carbonate, is low in cost and beneficial to environmental protection and energy conservation. The sheet-shaped mould plastic manufactured by virtue of the method is high in technical content, stable in process, relatively low in cost, strong in bearing capacity; and a product manufactured by virtue of the sheet-shaped mould plastic has the characteristics of tight matching, wear resistance, corrosion resistance, a light structure, an attractive style, light weight and easiness in installation, is remarkable in social benefit and economic benefit.

Owner:LINAN JUFENG URBAN SUPPORT EQUIP

High-frequency electromagnetic steam engine

ActiveCN103017126ATake advantage ofCompact structureSteam generation heating methodsSteam pressureAutomatic control

The invention belongs to the technical field of heating devices and relates to a high-frequency electromagnetic steam engine. The defect that high-temperature and low-pressure steam and high-temperature and high-pressure steam are high in water content in the prior art is overcome by the invention. Conduction oil is not needed, and the thermal efficiency is higher. The high-frequency electromagnetic steam engine comprises a water supply system, a tank, a water inlet pipeline and a steam pipeline, wherein the water inlet pipeline and the steam pipeline are respectively communicated with the interior of the tank. The high-frequency electromagnetic steam engine also comprises a high-pressure electromagnetic coil, a high-pressure electromagnetic generating device, a steam temperature sensor and a programmable logic controller (PLC) electronic control system, wherein the high-pressure electromagnetic coil is wound at the periphery of the tank; the high-pressure electromagnetic generating device is mutually connected with the high-pressure electromagnetic coil; the steam temperature sensor is arranged in the tank; the PLC electronic control system is used for performing automatic control on the temperature and the pressure of the steam to be treated and equipment; the steam pipeline is connected with a steam pressure sensor; and the high-pressure electromagnetic generating device, the steam temperature sensor and the steam pressure sensor are respectively and mutually connected with the PLC electronic control system. The steam is generated by utilizing electromagnetic energy, so that the high-frequency electromagnetic steam engine is high in thermal efficiency, is environmentally friendly and is convenient in maintenance.

Owner:缪桂道

Desulfurizing, denitrifying and decoking synergic additive for fire coal and preparation method of additive

The invention discloses a desulfurizing, denitrifying and decoking synergic additive for fire coal and a preparation method of the additive. The invention relates to the fields of desulfurizing and denitrifying, and particularly relates to a preparation method of an additive integrating desulfurization, denitrification, decoking and synergism in a process of combusting sulphur coal and coal. According to the additive and the preparation method disclosed by the invention, in an original coal combusting stage, a catalytic synergist which accounts for 0.1-0.8wt% of the total weight of the original coal is added into the fire coal, and meanwhile, a catalytic activating synergist which accounts for 0.02-0.2wt% of total weight of desulfuration slurry is further added into a slurry box of a desulfurization system. Under the premise of not changing an existing device, the catalytic activating synergist has the functions of saving coal, cleaning ash, decoking, desulfurizing and denitrifying to combustion of sulphur coal in a boiler. The catalytic activating synergist enhances the activity of lime stones in lime stone slurry and improves the desulfurizing efficiency as well as increases the denitrifying function, and meanwhile, the desulfurizing and denitrifying functions can reach or exceed national standards, so that the investment on selective catalytic reduction (SCR) and selective non-catalytic reduction (SNCR) denitrifying equipment is lowered, and huge economical benefit and environment-friendly benefit are obtained.

Owner:高同柱

Flake molding compound for manufacturing manhole cover and preparation method of flake molding compound

The invention firstly provides a flake molding compound for manufacturing a manhole cover which is environment-friendly and low in cost. The middle core of the flake molding compound is composed of glass fiber cloth dipped with resin paste, the glass fiber content is 20-40 parts, the resin paste comprises the following materials: 19-23 parts of unsaturated resin, 6-8 parts of low shrinking agent, 1.4-1.6 parts of styrene, 0.5-1.5 parts of curing agent, 1.5-1.7 parts of zinc stearate, 0.01-0.03 part of benzoquinone, 0.2-0.3 part of pigment paste, and 40-50 parts of 800-1000-mesh heavy calcium carbonate. The invention further provides a method for preparing the flake molding compound. The flake molding compound provided by the invention adopts base raw material in low cost, and waste heavy calcium carbonate is adopted, so that the flake molding compound is environmentally friendly and energy-saving. The flake molding compound manufactured by using the method disclosed by the invention is high in technical content, stable in process, low in cost and strong in bearing capacity. The product disclosed by the invention is manufactured as an article which is tight in matching, wear-resistant, corrosion-resistant, light in structure, beautiful in style, light in self weight and easy to install. The social benefit and the economic benefit are obvious.

Owner:LINAN JUFENG URBAN SUPPORT EQUIP

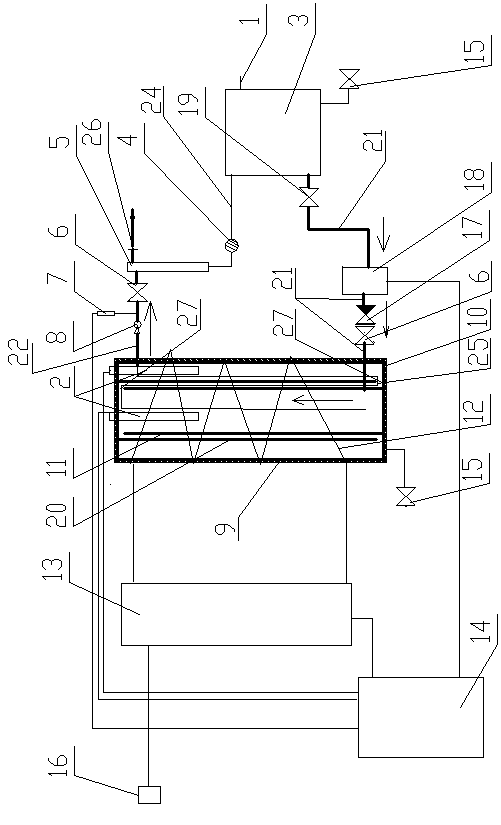

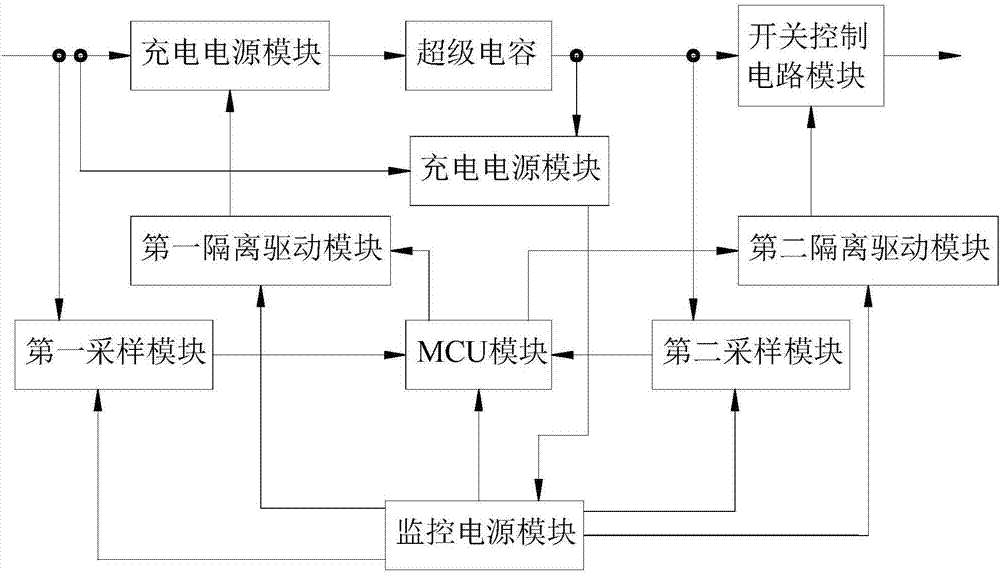

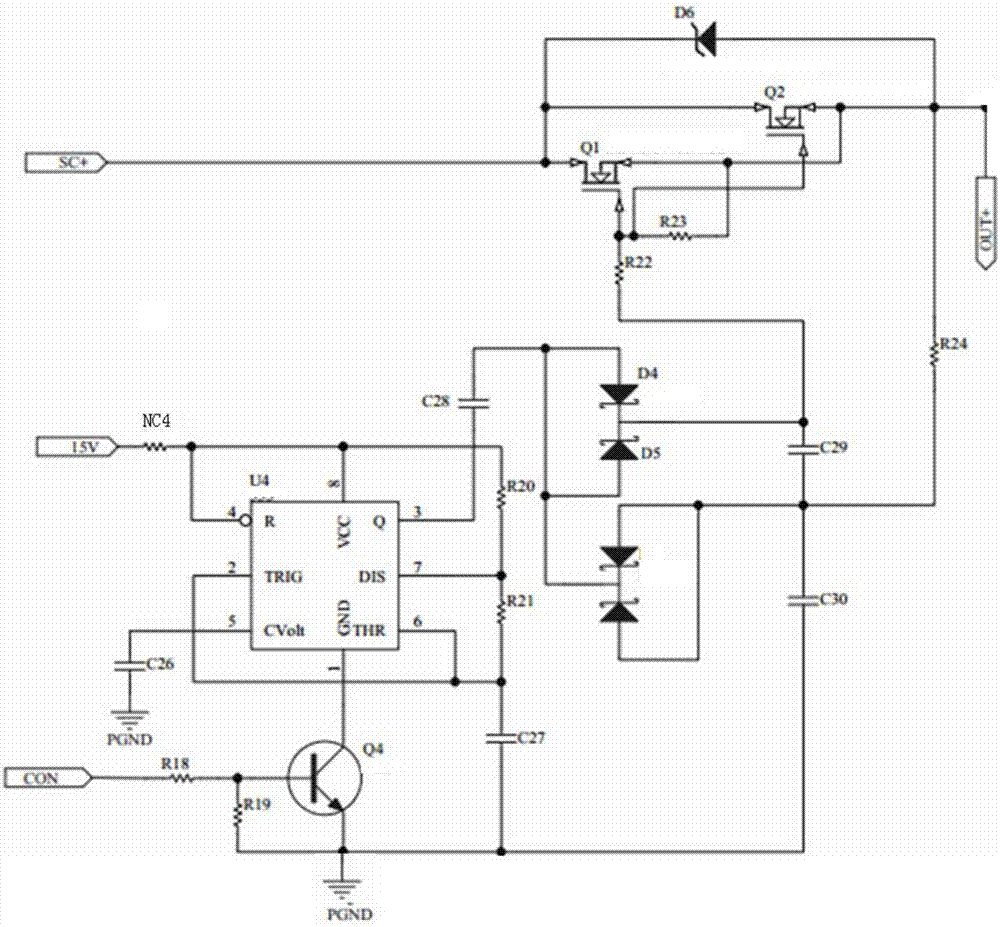

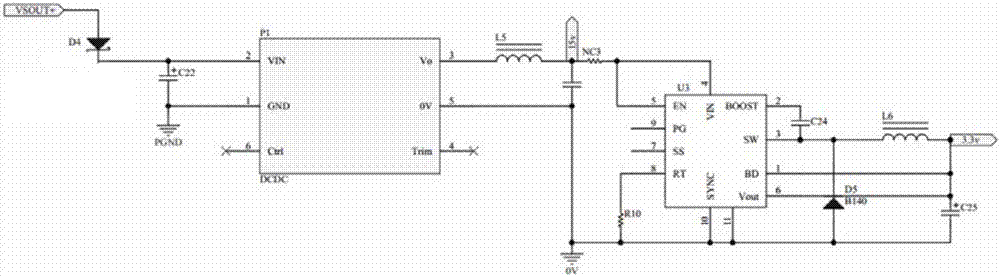

Power compensator charging capacitor power storage management system

ActiveCN107359680AReduce energy consumptionAvoid consumptionBatteries circuit arrangementsElectric powerCapacitor voltagePower switching

The invention provides a power compensator charging capacitor power storage management system, which comprises a charge and discharge unit and a monitoring unit. The charge and discharge unit comprises a charging power supply module, a super capacitor and an on-off control circuit module. The input end of the charging power supply module is connected to an input power supply; the output end of the charging power supply module is connected to the positive pole of the super capacitor; the negative pole of the super capacitor is connected to the input end of the on-off control circuit module; and the output end of the on-off control circuit module is connected to a load. The monitoring unit comprises an MCU module, a first sampling module, a second sampling module, a first isolation driving module, a second isolation driving module and a monitoring power supply module. The charge and discharge unit also comprises a power switch module. The power compensator charging capacitor power storage management system solves the problem of high power consumption due to mutual power supply of a first super capacitor voltage compensation unit and a second super capacitor voltage compensation unit in the prior art.

Owner:CHONGQING DAJI ELECTRONICS TECH

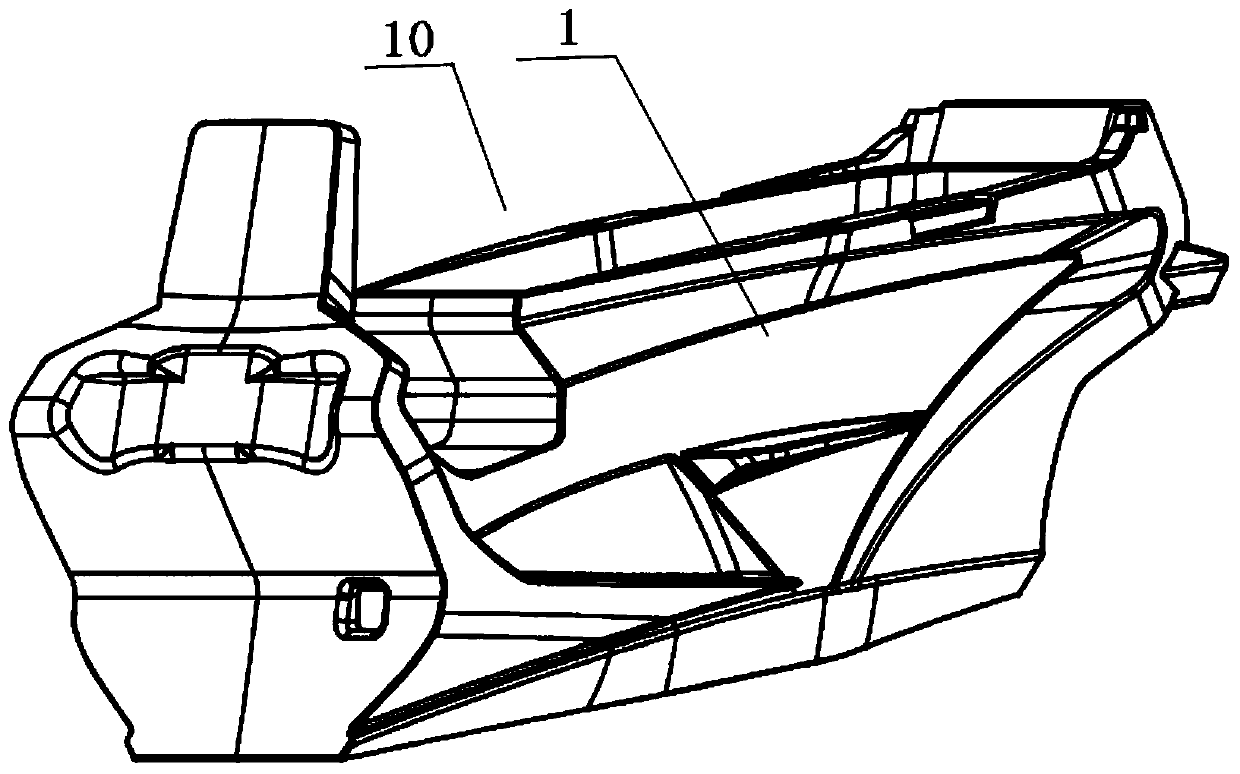

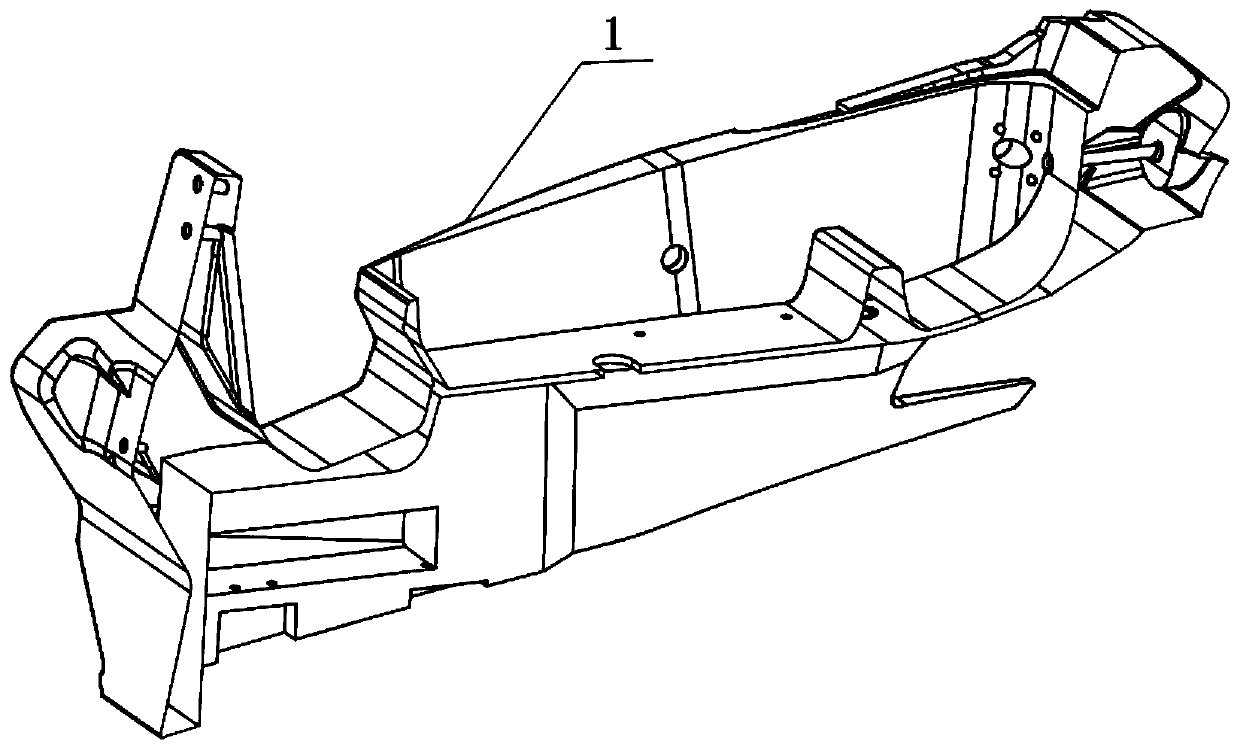

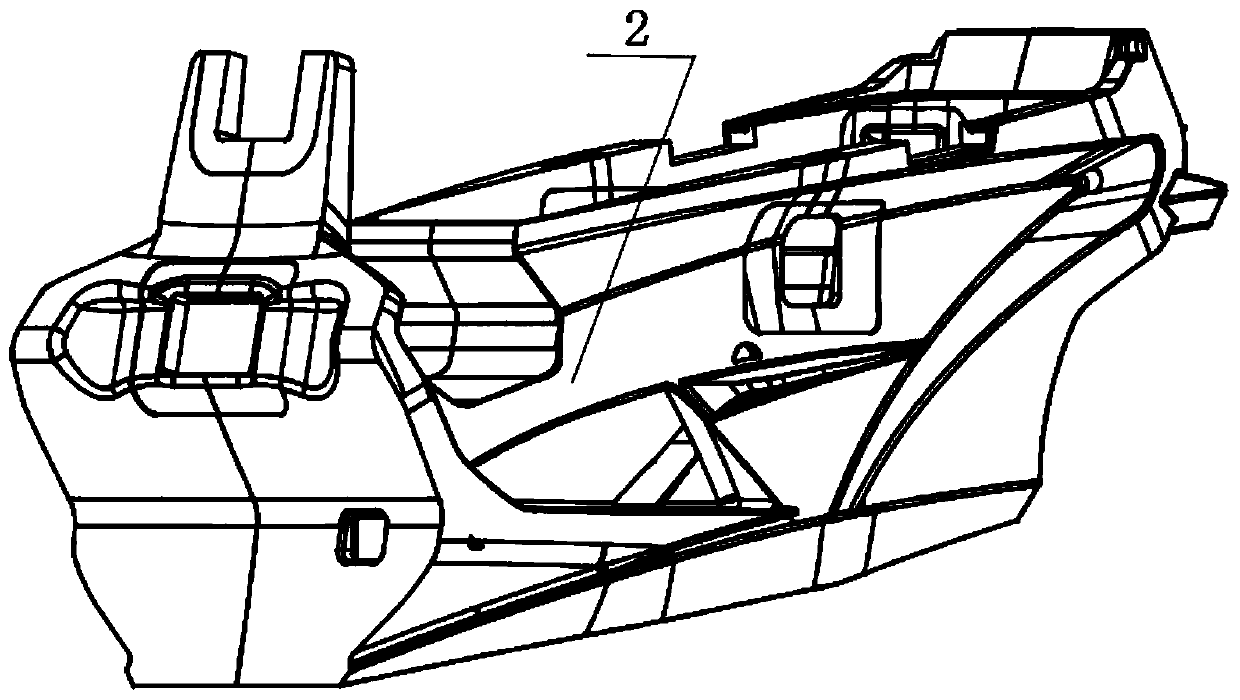

Integrated motorcycle body and manufacturing method thereof

The invention discloses an integrated motorcycle body and a manufacturing method thereof. The integrated motorcycle body comprises a polyurethane foaming filler, a carbon fiber surface layer and an aluminum alloy embedded part, wherein the polyurethane foaming filler is a motorcycle body shape core body, the carbon fiber surface layer is the outer surface shell layer formed on the surface of the motorcycle body shape polyurethane foaming filler core body, the carbon fiber surface layer is soaked by epoxy resin and a curing agent to form a reinforcing body, and the aluminum alloy embedded partis arranged on the stress point of the polyurethane foaming filler. According to the volume percentage, the polyurethane foaming filler containing the aluminum alloy embedded part accounts for 75%-90%, and the surface layer of the carbon fiber infiltrated with the epoxy resin and the curing agent accounts for 10%-25%. The preparation method comprises the following steps of preparing the core body,embedding the aluminum alloy embedded part, cutting a carbon fiber sheet body, manufacturing a preform, heating the mold, RTM injection molding and paint spraying.

Owner:YINGKOU FLYING DRAGON CARBON E VEHICLE CO LTD

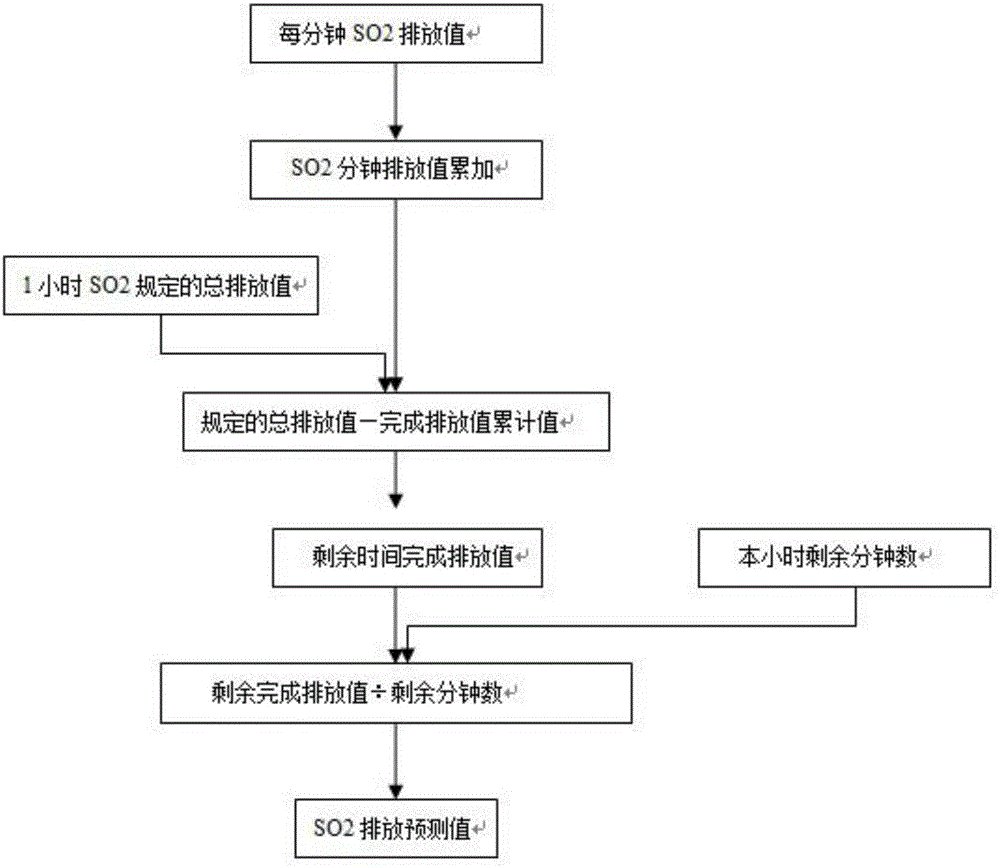

Method for predicting pollutant emission value of power plant

InactiveCN106290737AImprove reliabilityConducive to environmental protection and energy savingMaterial analysisPollutant emissionsEngineering

The invention provides a method for predicting a pollutant emission value of a power plant and relates to the technical field of the power plant. The method is characterized by comprising steps as follows: an actual pollutant emission value every minute is measured and accumulated, a value of emission to be completed in remaining time is obtained by subtracting an accumulated value of completed emission values from a stipulated total pollutant emission value every hour, and a prediction value of pollutant emission is obtained by dividing the value of emission to be completed in the remaining time by remaining minutes. With the adoption of the method, an hourly average of completion of environmental protection indexes does not exceed the standard when environmental protection equipment is abnormal or during starting and stopping of a unit, the calculation is simple, the reliability is high, and environmental protection and energy conservation are facilitated.

Owner:HUAIHU ELECTRIC POWER

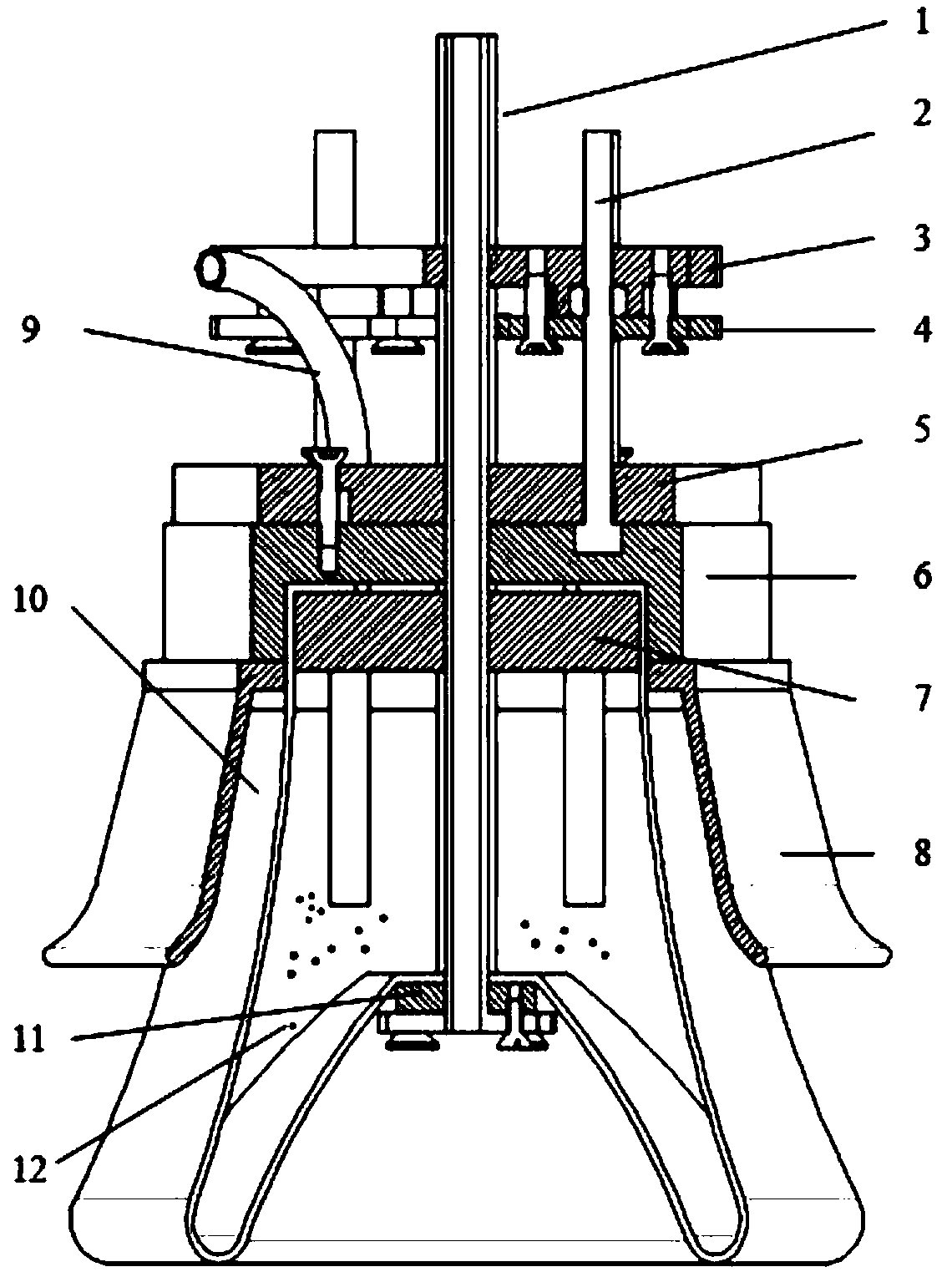

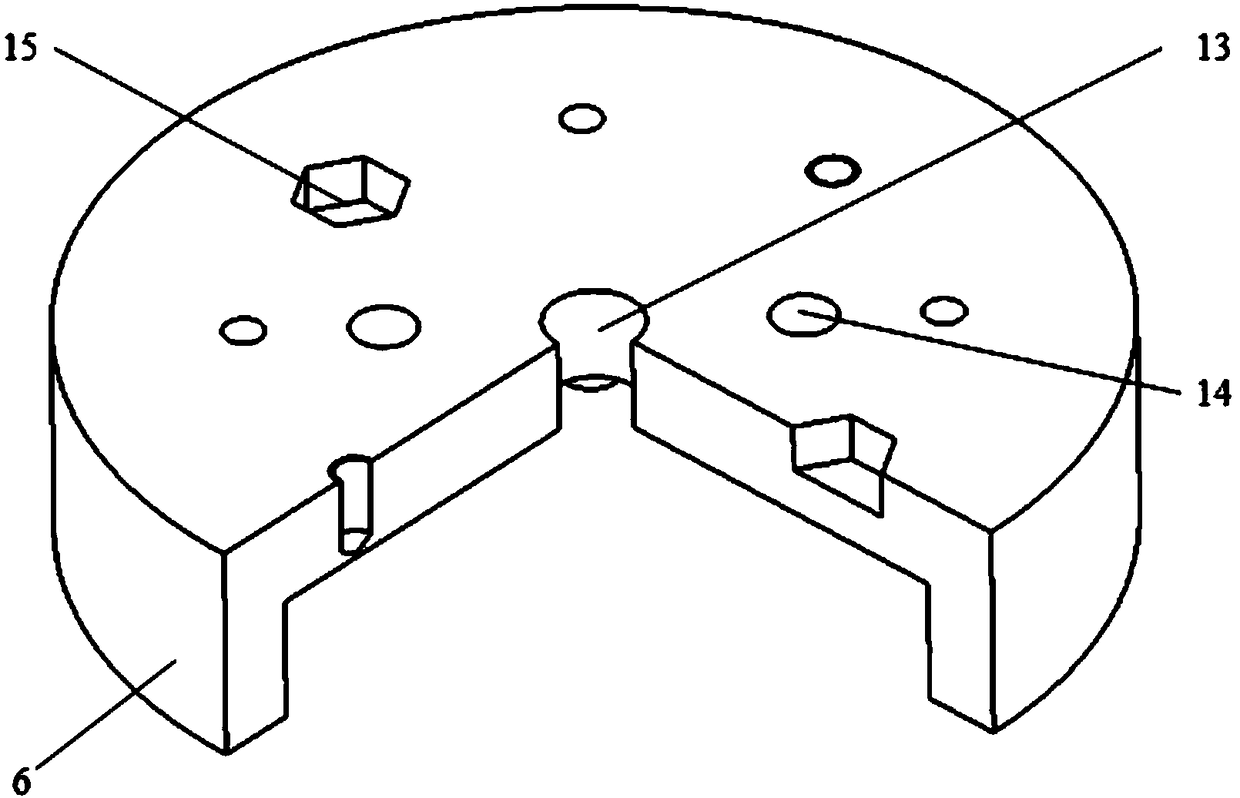

Vacuum cup based on particulate matter moulding

InactiveCN108483037AImprove fitEffective adsorption and clampingConveyor partsThin membraneEngineering

The invention discloses a vacuum cup based on particulate matter moulding. The vacuum cup comprises a thin film attached to the surface of an object. The thin film is filled with a particle material,an inner connecting plate is embedded to the neck portion of the thin film, and two blind holes are formed in the upper portion of the inner connecting plate. An upper end cover achieves locating andconnecting through the two blind holes of the inner connecting plate. The lower surface of the upper end cover is connected with a fixed cover for preventing excessive deformation of the thin film, two limiting bolts are embedded to the upper surface of the upper end cover, and the limiting bolts are fixed through connection between the locating plate and the upper end cover. A hose passes throughthe center of the locating plate, the bottom of the hose is connected with the top plate, and the top plate is attached to the bottom of the thin film. The hose ascends and descends through a hose fixing part, meanwhile, the top plate is driven to form changing of the concave depth of the bottom of the thin film, and a suction cup shape with the edge being annular is formed due to the fact that the bottom of the thin film is concave, and the aims of attachment and moulding can be achieved well.

Owner:NANJING UNIV OF SCI & TECH

Formula of antibacterial and heat preserving material for refrigerators

InactiveCN103214754AReduce power consumptionWith insulationChemical industryIceboxPolyvinyl chloride

The invention discloses a formula of an antibacterial and heat preserving material for refrigerators. According to the formula, the material comprises the following components by weight: 100 parts of PVC (polyvinyl chloride), 10-15 parts of AgNO3, 2-5 parts of ZnSO4, 10-15 parts of zeolite powder with a particle size of 2000-3000 meshes, 3-5 parts of diatomite, 1-2 parts of perlite, 5-10 parts of a bacterial inhibitor, and 0.5-1 part of an aluminic ester coupling agent. The formula provided in the invention can achieve the effects of heat preservation and sterilization, and can reduce the power consumption of refrigerators, thus being conducive to environmental protection and energy saving.

Owner:青岛永卓真塑料制品有限公司

Method for preparing composite resin manhole cover through cooperation between non-metal powder of waste circuit boards and polyester resin

InactiveCN108821645ASimple manufacturing processShorten the production cycleArtificial islandsSolid waste managementResin-Based CompositePrinted circuit board

The invention discloses a method for preparing a composite resin manhole cover through cooperation between non-metal powder of waste circuit boards and polyester resin. According to the invention, non-metal materials of waste printed circuit boards are used as a main raw material for preparation of the manhole cover; the non-metal materials are rich in glass fibers and thermosetting resin, and arereasonably treated and then compounded with unsaturated polyester resin for preparation of the composite resin manhole cover; the unsaturated polyester resin has low viscosity, conducts good infiltration action on the glass fibers in the non-metal powder of waste printed circuit boards, and is rapid in pressure curing; so a prepared cured compound has sufficient toughness and does not crack. Thepreparation method for the manhole cover in the invention is simple and rapid in process, short in production cycle and high in efficiency; since industrial waste is used as a main raw material, production cost is reduced, and environmental protection and energy conservation are facilitated; and the prepared manhole cover is high in bearing capacity, has the characteristics of tight fitting, wearresistance, corrosion resistance, light structure, beautiful appearance, light weight and easy installation, and has been applied in related projects.

Owner:安徽大来机械制造有限公司

Surface treatment method of ribbed stainless steel bar

InactiveCN110344042AEasy to cleanEasy to useMetallic material coating processesGranularitySulfamic acid

The invention relates to a metal surface treatment method, in particular to a surface treatment method of a ribbed stainless steel bar. The surface treatment method comprises the following steps of (S1) performing shot blasting treatment on the ribbed stainless steel bar: performing the shot blasting treatment on the hot rolling ribbed stainless steel bar, wherein the shot blasting granularity is0.15 to 0.6 mm, the shot blasting speed is 40 to 100 m / s, the shot blasting flow is 60 to 160 kg / m<2>, and the surface scale of the ribbed stainless steel bar is cleaned basically after the shot blasting treatment is performed; (S2) pickling the ribbed stainless steel bar on which the shot blasting treatment is performed by adopting a pickling solution, wherein effective components of the picklingsolution include boric acid and sulfamic acid (NH2SO3H), and flushing for many times after pickling; (S3) performing passivating treatment on the pickled ribbed stainless steel bar, wherein a passivating solution is a mixed solution of sulfamic acid and water; (S4) performing scalding treatment on the passivated ribbed stainless steel bar; and (S5) naturally airing the scalded ribbed stainless steel bar. Compared with a stainless steel surface treatment process in the prior art, the surface treatment method has the advantages of good surface quality, environmental friendliness and energy conservation.

Owner:ZHEJIANG RUIPU TECH

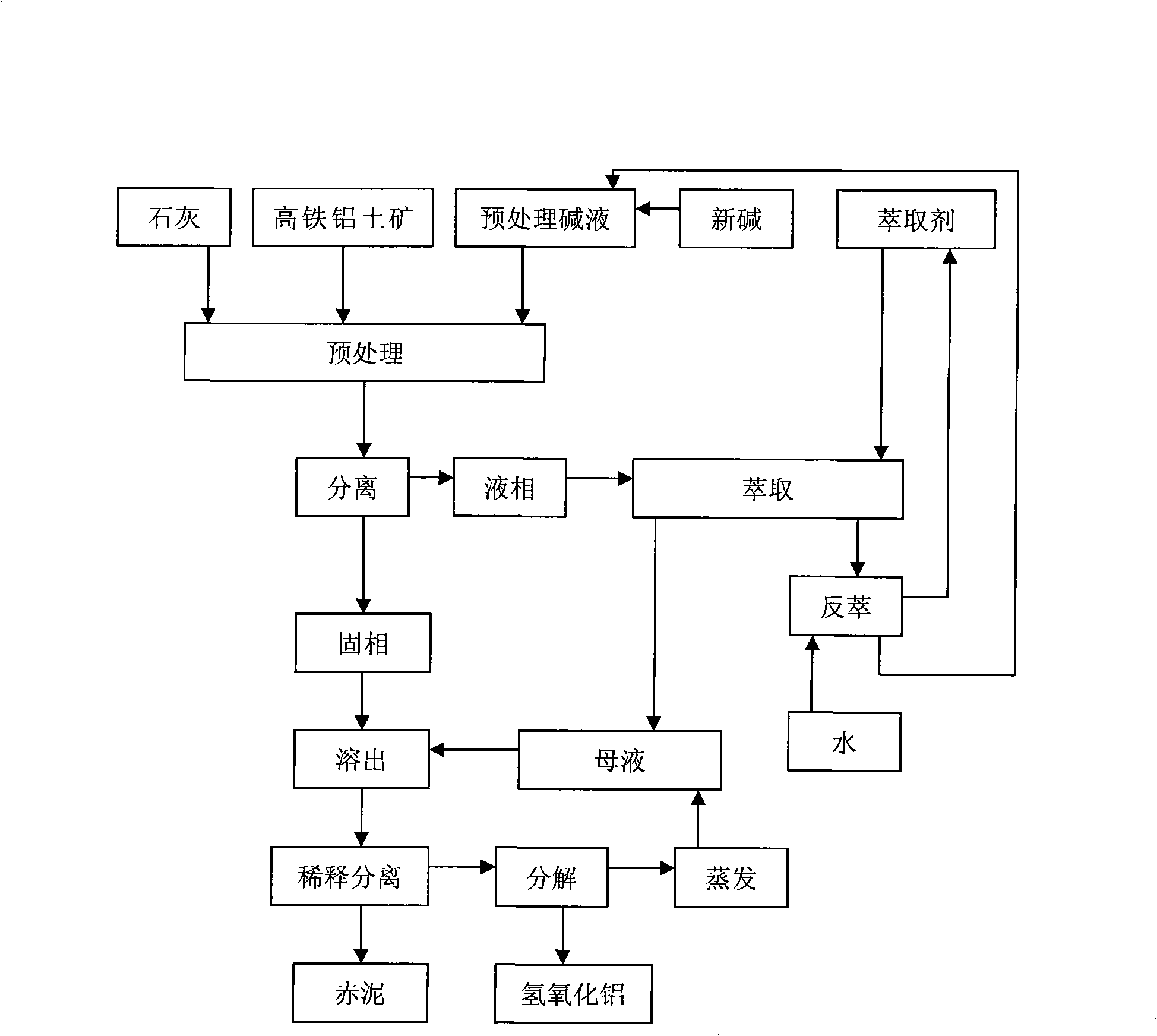

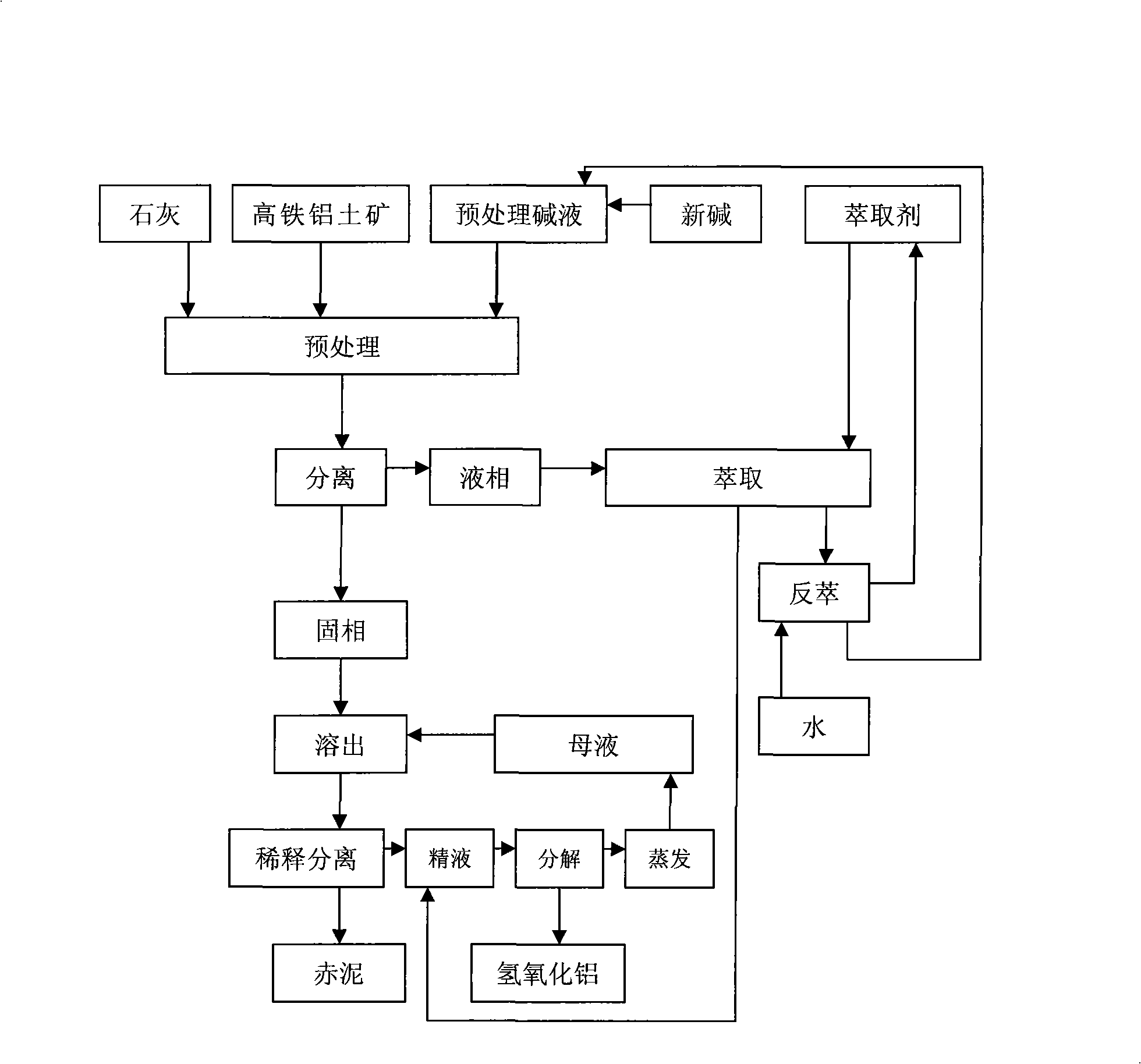

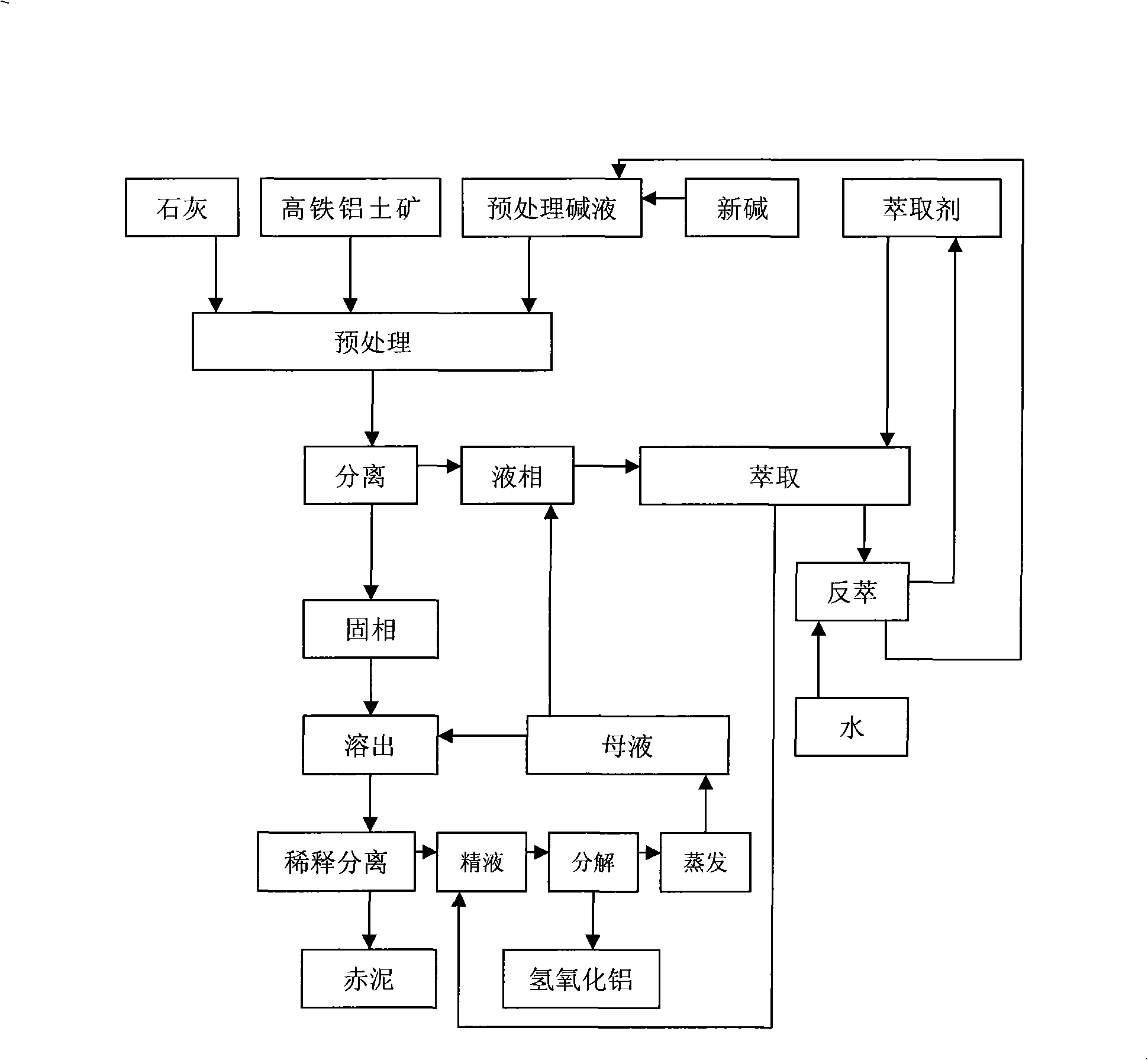

Stripping process for diaspore ore

The invention provides a method for dissolving out a diaspore ore, which relates to a preprocessing process of adding lime into ore slurry in the process for dissolving out ferric-diaspore ore and a regeneration method of pre-processing alkali solution. The method is characterized in that during the dissolving-out process, ferric-bauxite ore is added with lime CaO and alkali solution for preprocessing and then carries out solid-liquid separation; the obtained solid is used for dissolving out under the conditions of normal Bayer process; the obtained liquid realizes the regeneration of the preprocessing alkali solution by a extraction method. The method of the invention only takes the lime as an additive and has simple procedures and obviously reduces the ratio of aluminum and silicon (A / S) and the ratio of natrium and silicon (N / S) in the dissolved-out red mud, which is applicable to processing a diaspore type bauxite with high content of ferric oxide (the content of Fe2O3 is higher than or is equal to 6 percent).

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Energy-saving and environmentally friendly material used in building and preparation method thereof

InactiveCN105948578AImprove performanceImprove crack resistanceCeramic shaping apparatusSodium BentoniteSlag

The invention discloses an energy-saving and environmentally friendly material used in building. The material comprises the following components: brominated polystyrene; synthetic resin emulsion; inorganic salts; ammonia propyl triethoxy silane; aldehyde acetone polycondensate; water repellent; lauryl dimethyl amine oxide; cement; slag 1; bentonite; and deionized water. The invention aims at the problem of the traditional organic insulation building material of poor fireproofing grade and the problems of the inorganic insulation building material such as high cost, low share and low output, and provides a fireproof adiabatic insulation material. The material uses slag having rich output as mainly raw material, is prepared from combining the slag with inorganic material and organic material, has good heat retaining property, fireproof property and low cost, and can be performed mass produce.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

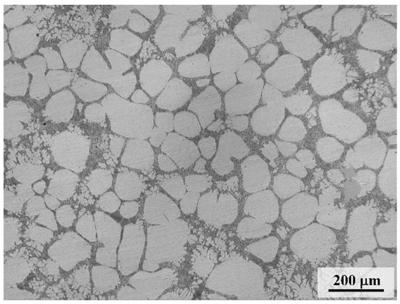

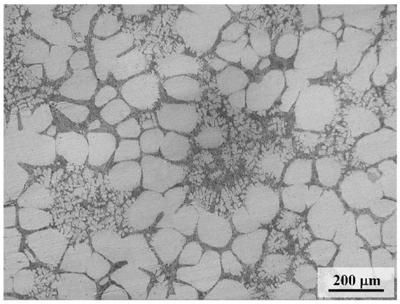

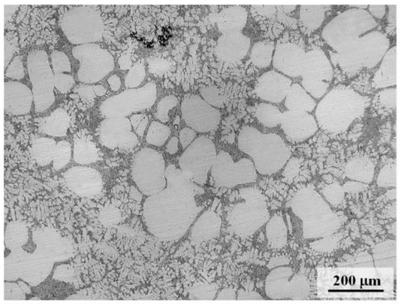

Self-breeding rod and preparation method thereof as well as preparation method of hypoeutectic aluminum-silicon alloy semi-solid slurry

The invention discloses a preparation method of hypoeutectic aluminum-silicon alloy semi-solid slurry. The preparation method comprises the following steps: step 1, heating a aluminum-silicon alloy base material until the base material is completely melted into a metal liquid, fully stirring to ensure the alloy compositions uniform, and standing still after degassing, refining and drossing; at thesame time, preheating an electromagnetic stirrer and then keeping warm; step 2, transferring the metal liquid after standing still to a crucible on the electromagnetic stirrer for standing, and stopping heating after the temperature is stabilized; step 3, starting to perform electromagnetic stirring on the metal liquid, inserting a self-breeding rod directly into the metal liquid, maintaining theelectromagnetic stirring, and pulling out the self-breeding rod when the temperature is lowered to 605-615 DEG C; step 4, turning off the electromagnetic stirrer when the temperature is lowered to 600 DEG C, and obtaining the hypoeutectic aluminum-silicon alloy semi-solid slurry; wherein, the aluminum-silicon alloy base material used in the preparation process of the self-breeding rod used in thestep 3 is the same as the aluminum-silicon alloy base material used in the step 1. The invention further discloses the self-breeding rod and the preparation method thereof.

Owner:JILIN UNIV

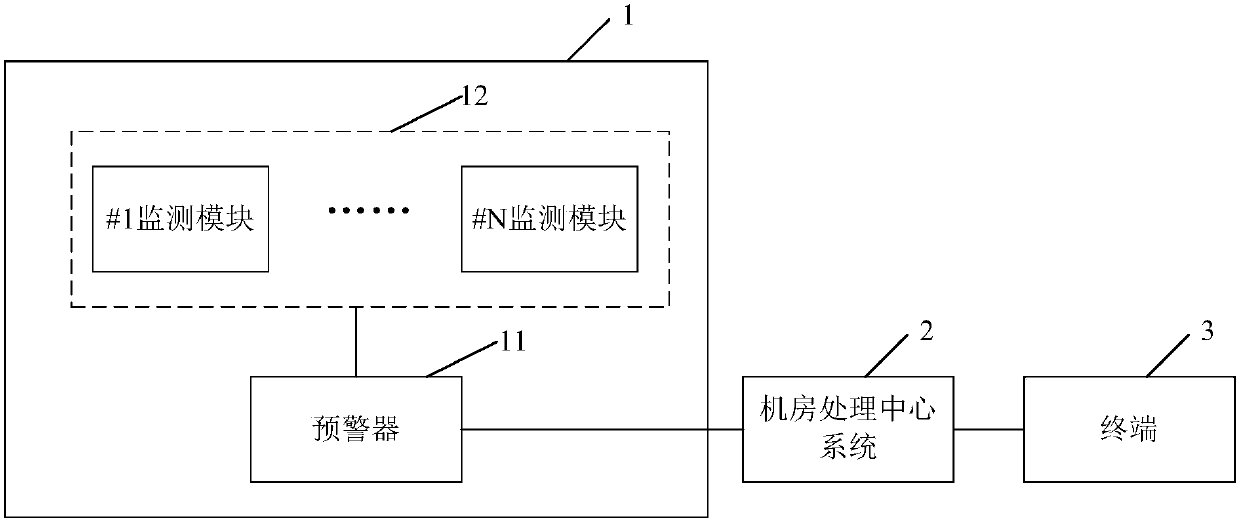

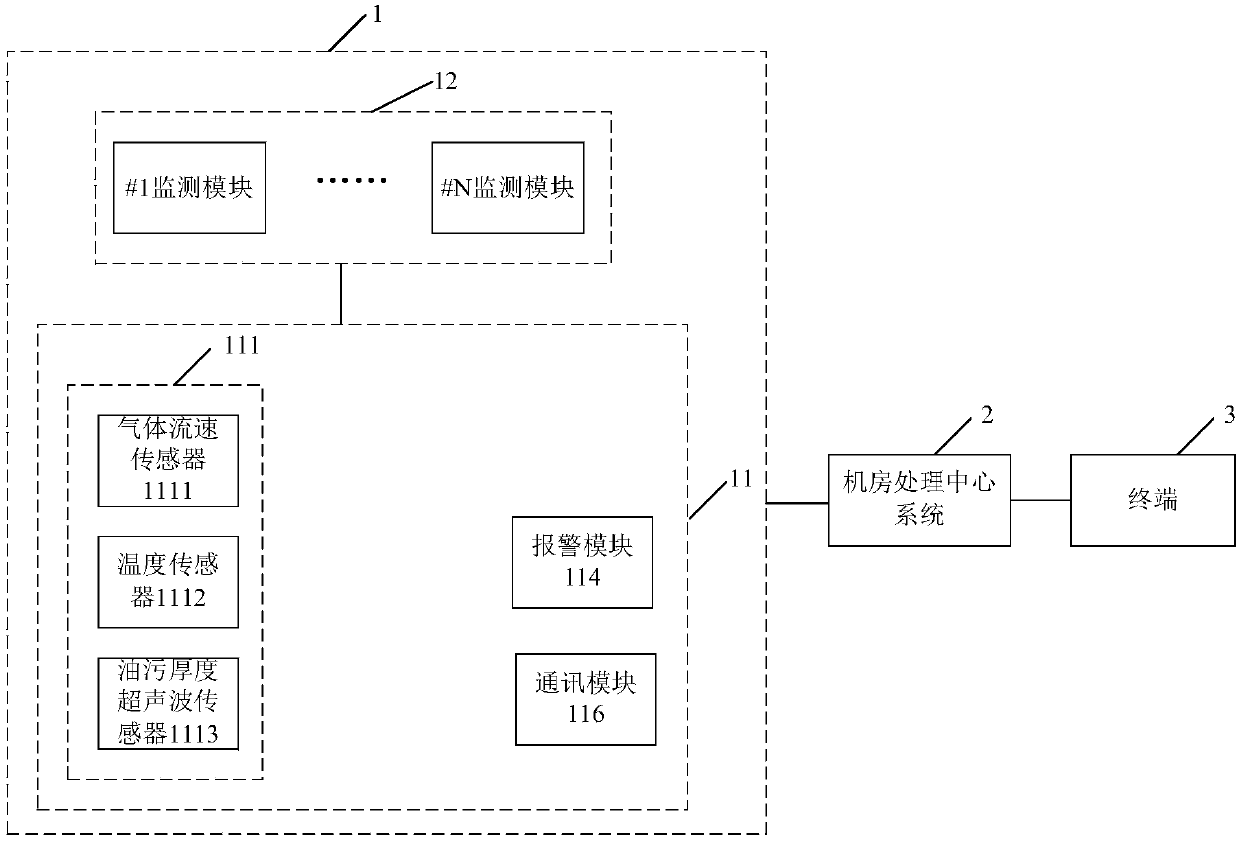

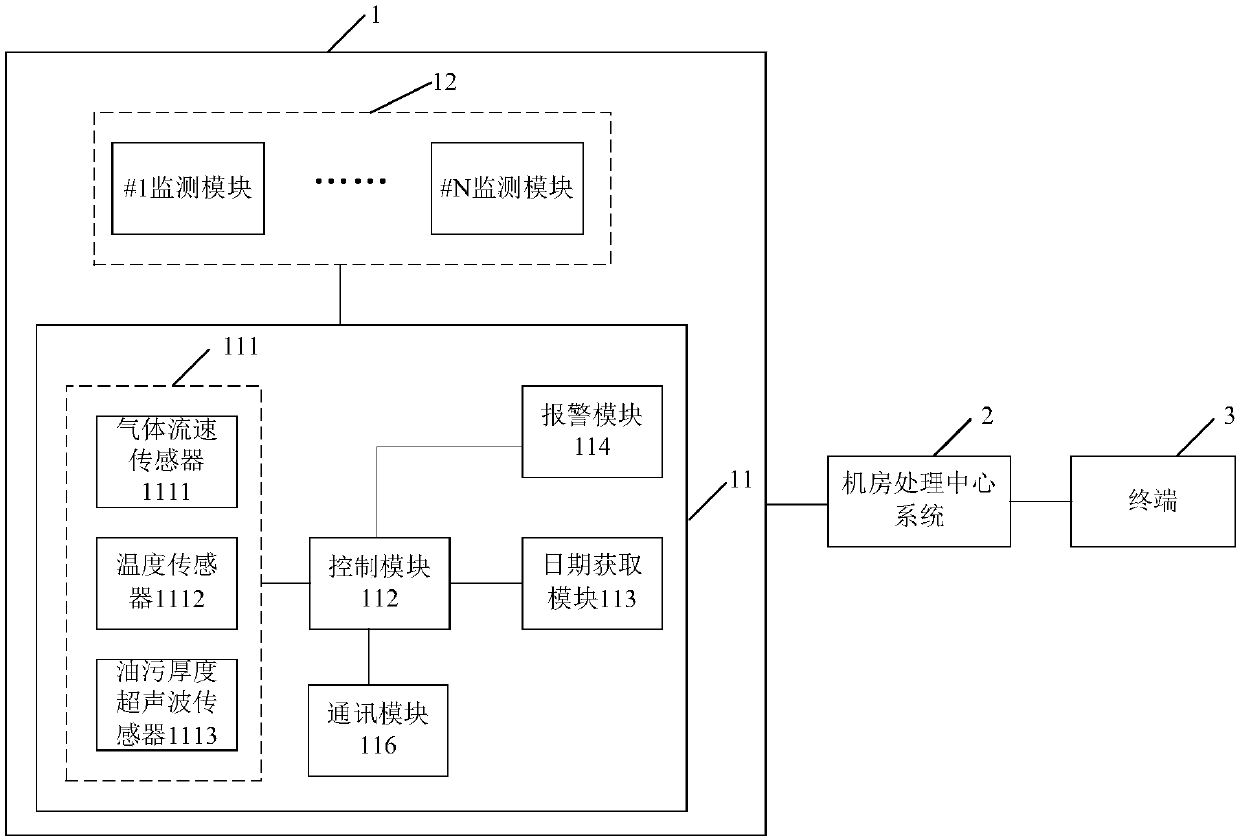

Flue fire warning monitoring system and method

The invention discloses a flue fire warning monitoring system and method. The system comprises an early warning unit arranged on a flue, a computer room processing center system communicatively connected with the early warning unit, and a terminal communicatively connected with the computer room processing center system. The early warning unit comprises an early warning device and a number of monitoring modules connected with the early warning device. The early warning device and a number of monitoring modules are arranged at different positions of the flue respectively, and acquire the firstenvironmental status information and the second environmental status information of the flue respectively. The computer room processing center system receives the first environmental status information and the second environmental status information, wherein the first environmental status information and the second environmental status information are output by the early warning device. The computer room processing center system analyzes and processes the first environmental status information and the second environmental status information based on the cleaning date information of the flue, outputs an early warning signal and early warning information according to the analysis result, and sends an early warning instruction to the early warning device to trigger an early warning. Accordingto the invention, the system and method are conducive to environmental protection and energy conservation; cleaning energy is saved; and real-time monitoring and fire early warning triggering are realized to avoid fire.

Owner:钱永民

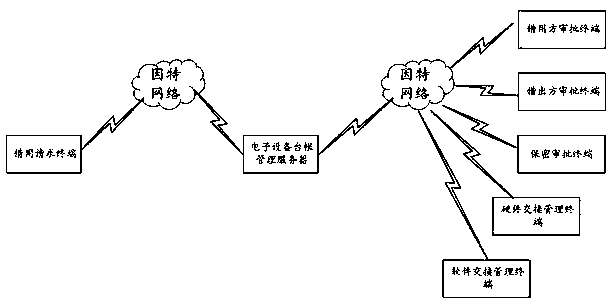

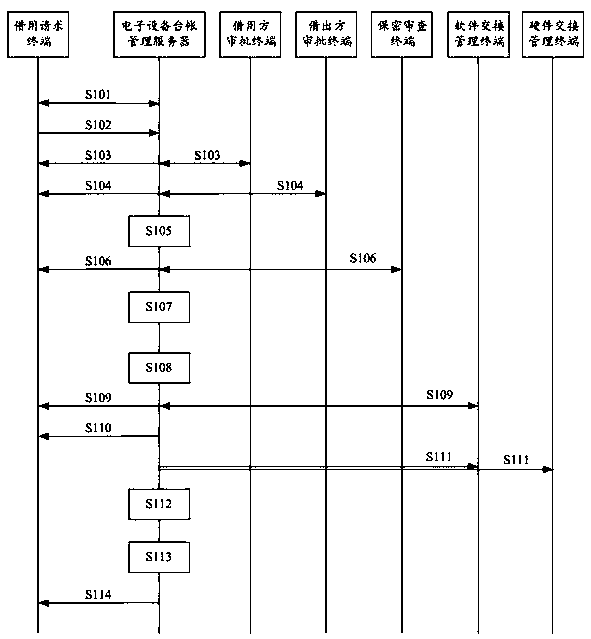

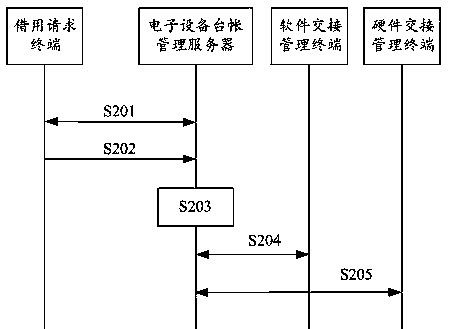

Online borrowing management system and management method for electronic equipment

ActiveCN108694499ARealize paperless operationConducive to environmental protection and energy savingSustainable waste treatmentResourcesInternet networkConfidentiality

The invention relates to the technical field of equipment management and in particular to an online borrowing management system and an online borrowing management method for electronic equipment. Thesystem comprises an electronic equipment ledger management server, a borrowing request terminal, a borrower approval terminal, a lender approval terminal, a confidentiality approval terminal, a hardware handover management terminal and a software handover management terminal, wherein the electronic equipment ledger management server is respectively connected with the borrowing request terminal, the borrower approval terminal, the lender approval terminal, the confidentiality approval terminal, the hardware handover management terminal and the software handover management terminal through an internet network. According to the online borrowing management system and the online borrowing management method for the electronic equipment, settlements of lending and returning formalities of the electronic equipment can be performed in an online manner, thereby implementing paperless work, being beneficial to environmental protection and energy saving, saving walking and approval time, accelerating an approval process, greatly reducing the labor cost and improving the working efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com