Energy-saving radiant tube component

A technology of radiant tubes and components, which is applied in the field of energy-saving radiant tube components, can solve the problems of low energy utilization rate and high flue gas temperature, and achieve the effects of improving energy utilization rate, high combustion temperature, and reducing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

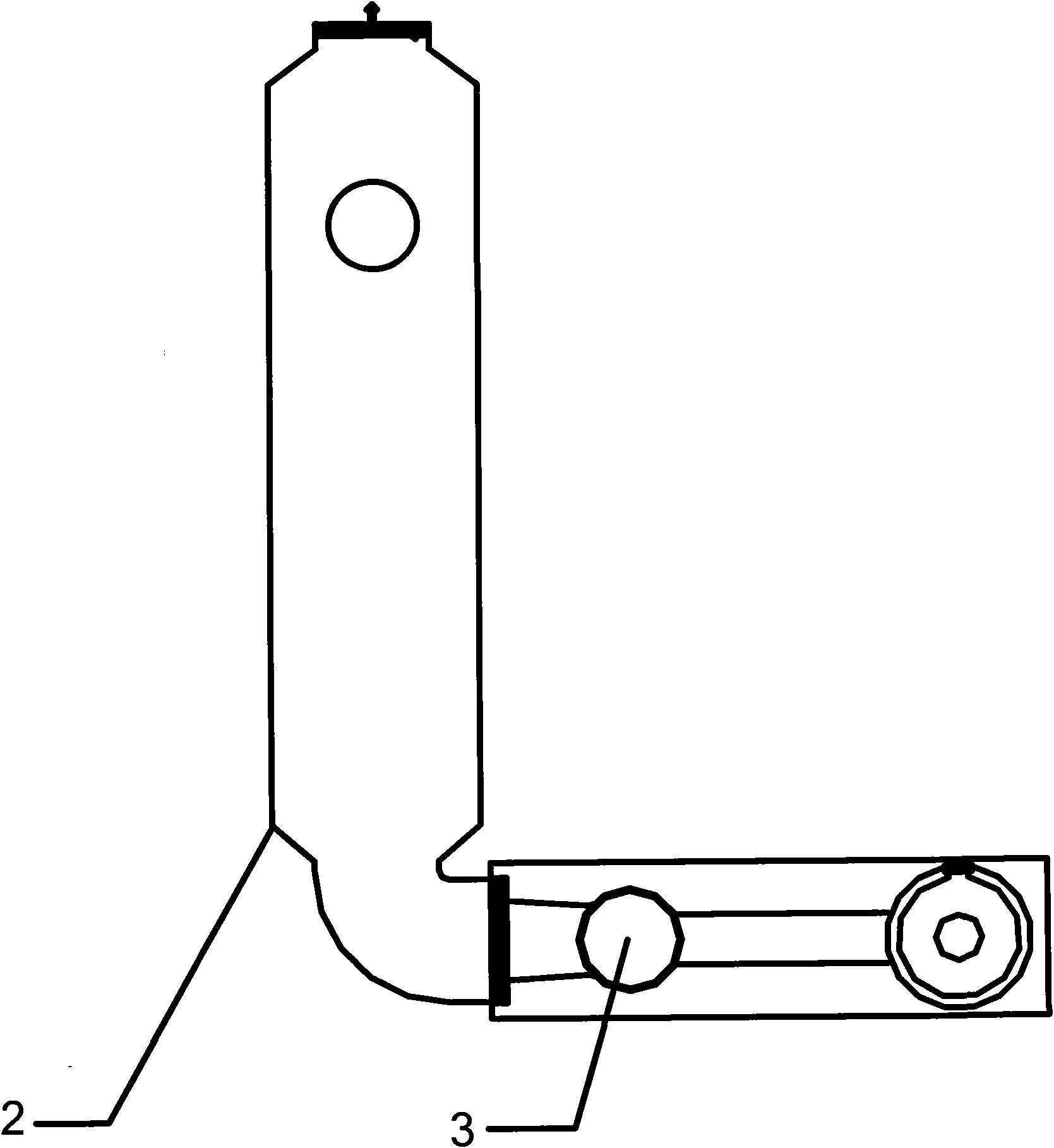

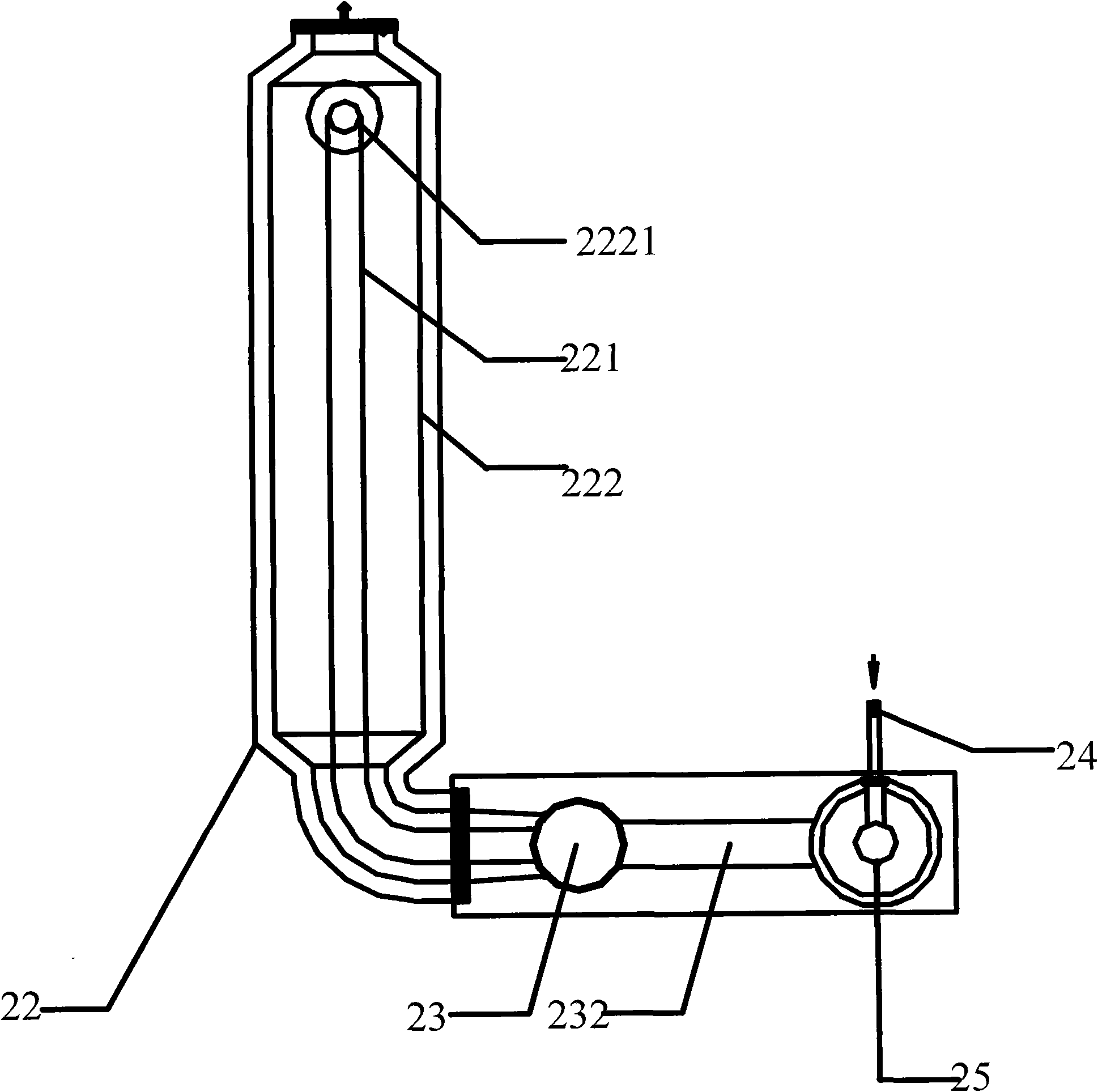

[0047] Such as Figure 2A-2B As shown, an energy-saving radiant tube assembly provided by an embodiment of the present invention includes a radiant tube 21, a primary heat exchanger 22 and a secondary heat exchanger 23, wherein:

[0048] The primary heat exchanger 22 includes: double-layer tubes, including inner tubes and outer tubes, wherein:

[0049] The outer tube is a first air tube 222, which has a first air inlet and a first air outlet for introducing air;

[0050] The inner pipe is the first flue gas pipe 221, which has a first flue gas inlet and a first flue gas outlet, and is used to receive and discharge the flue gas introduced by the secondary heat exchanger 23, and use the heat of the flue gas to guide the first flue gas. The air in the air pipe 222 is preheated for the first time;

[0051] The first air pipe 222 is also used to lead the first preheated air to the secondary heat exchanger 23 .

[0052] The secondary heat exchanger 23 includes a second flue gas p...

Embodiment 2

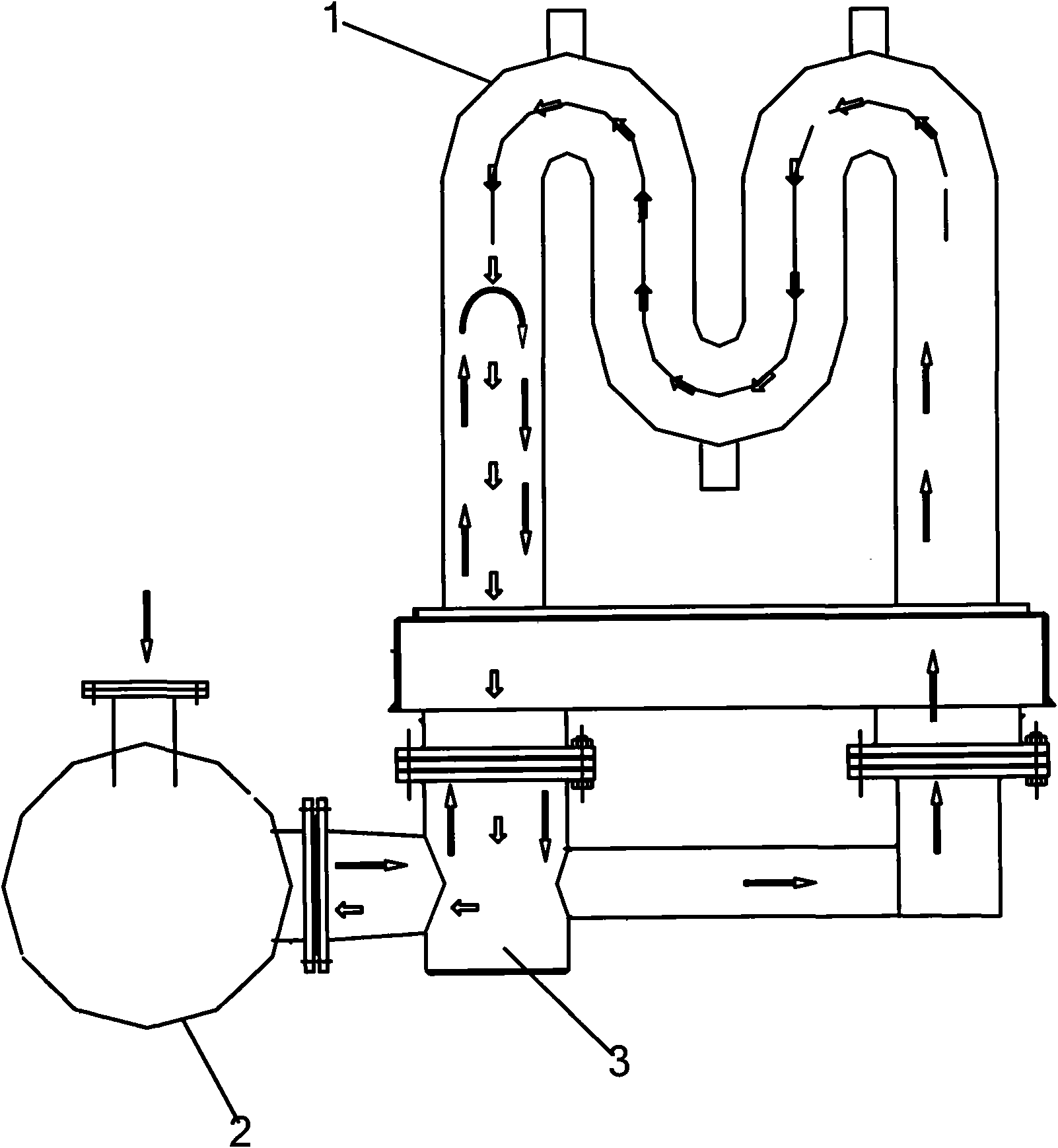

[0064] Such as Figure 3A-3B As shown, another energy-saving radiant tube assembly provided by the embodiment of the utility model includes a radiant tube 31, a primary heat exchanger 32 and a secondary heat exchanger 33, wherein:

[0065] The primary heat exchanger 32 includes: a double-layer tube, including an inner tube and an outer tube, wherein:

[0066] The inner tube is a first air tube 322, which has a first air inlet and a first air outlet, and is used to introduce air;

[0067] The outer pipe is the first flue gas pipe 321, which has a first flue gas inlet and a first flue gas outlet, and is used to receive and discharge the flue gas introduced by the secondary heat exchanger 33, and use the heat of the flue gas to guide the first flue gas. The air in the air pipe 322 is preheated for the first time;

[0068] The first air pipe 322 is also used to lead the first preheated air to the secondary heat exchanger 33 .

[0069] The secondary heat exchanger 33 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com