High-frequency electromagnetic steam engine

A high-frequency electromagnetic and steam engine technology, used in steam generation, steam generation methods, lighting and heating equipment, etc., can solve the problems of large steam water content and high thermal efficiency, and achieve compact equipment structure, reduced floor space, and energy utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

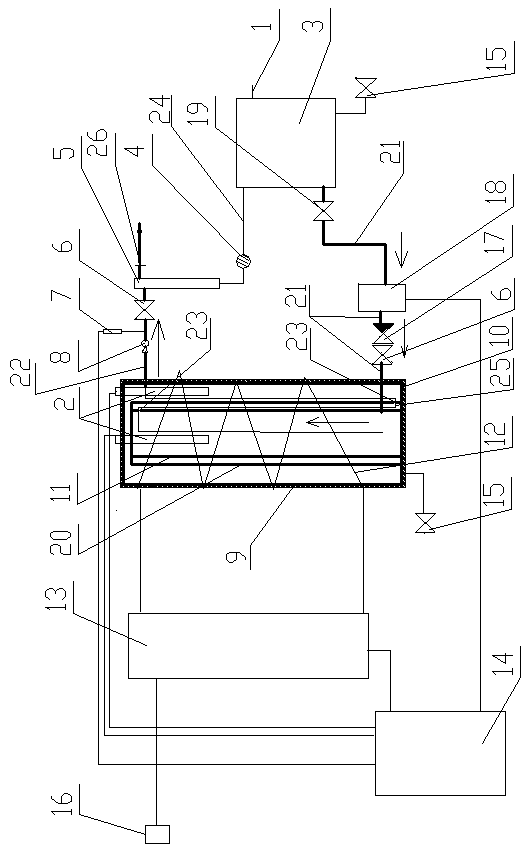

[0023] Such as figure 1 The shown electromagnetic steam engine includes a water supply system, a tank body 10, a water inlet pipeline 21 and a steam pipeline 22 respectively communicated with the inside of the tank body, a high-frequency electromagnetic coil 12 wound around the periphery of the tank body 10, and a high-frequency electromagnetic coil. A high-frequency electromagnetic generator 13 connected to the coil, a steam temperature sensor 2 installed in the tank, and a PLC electronic control system 14 for processing the temperature and pressure of the steam and automatically controlling the equipment. The steam pipeline is connected with a steam pressure sensor 7 , and the high-frequency electromagnetic generator 13 , the steam temperature sensor 2 and the steam pressure sensor 7 are respectively connected with a PLC electric control system 14 . The high-frequency electromagnetic generating device 13 is connected to a power source 16 .

[0024] The tank body 10 is wrapp...

Embodiment 2

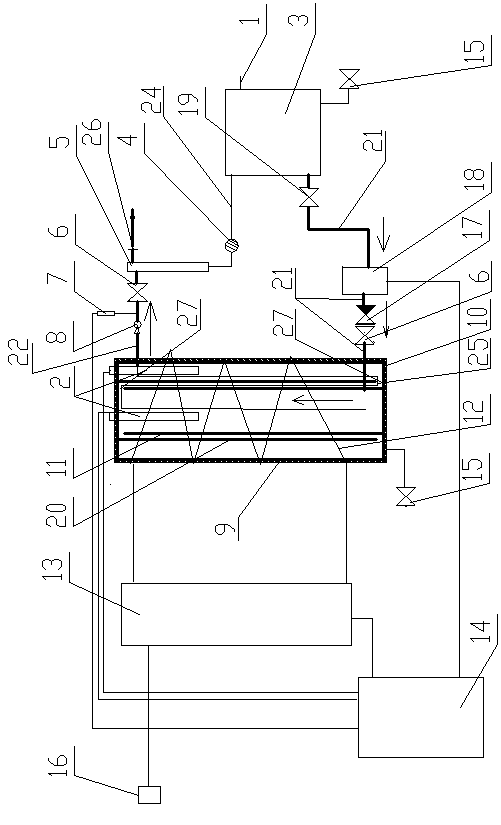

[0031] Such as figure 2 Shown a kind of electromagnetic steam engine, specific structure is the same as embodiment 1, and difference is the structure and the arrangement mode of inner sleeve and middle sleeve, specifically as follows:

[0032] Both the middle sleeve 20 and the inner sleeve 11 are cylindrical bodies with upper and lower openings, the top of the middle sleeve 20 is connected to the top of the tank body, and the bottom of the inner sleeve 11 is fixedly connected to the bottom of the tank body. The top of the inner sleeve and the upper surface of the tank, the bottom of the middle sleeve and the lower surface of the tank respectively leave a gap 27 for the passage of steam, and the steam and water vapor generated in the inner sleeve flow out through the gap 27, that is, the inner sleeve The gap at the top of the barrel and the gap at the lower end of the middle sleeve form a baffle passage 25 for steam to flow.

Embodiment 3

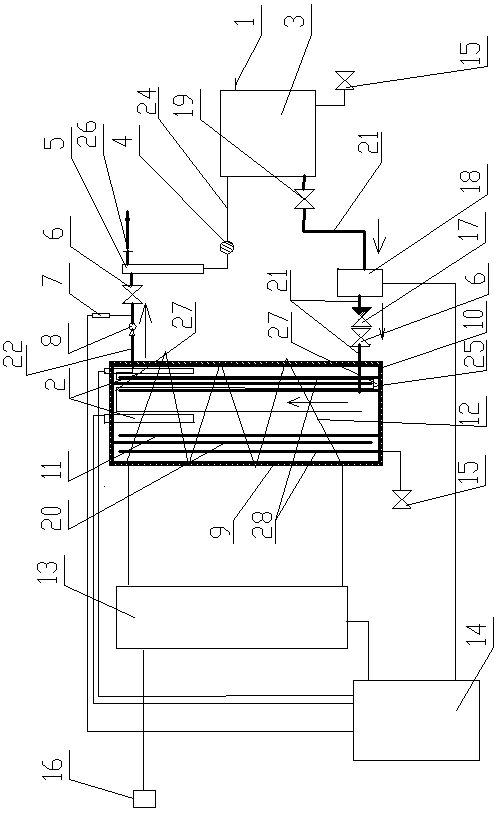

[0034]An electromagnetic steam engine, the specific structure is the same as in Example 1, the difference is that the outer diameter of the tank body described in this embodiment is 120 mm, and the thickness of the tank body is 8 mm; the outer diameter of the inner sleeve is 50 mm, and the thickness of the tank body is 8 mm. 3mm; the outer diameter of the intermediate sleeve is 90mm, and the thickness of the tank body is 4.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com