Small-sized diaphragm pump simulation frequency changing system and control method thereof

A frequency conversion system and diaphragm pump technology, applied in pump control, liquid variable capacity machinery, machines/engines, etc., can solve the problems of not improving the recovery rate, differences in individual parameters of diaphragm pumps, changes in medium circulation flow rate, etc., to simplify the quality. The effect of controlling difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

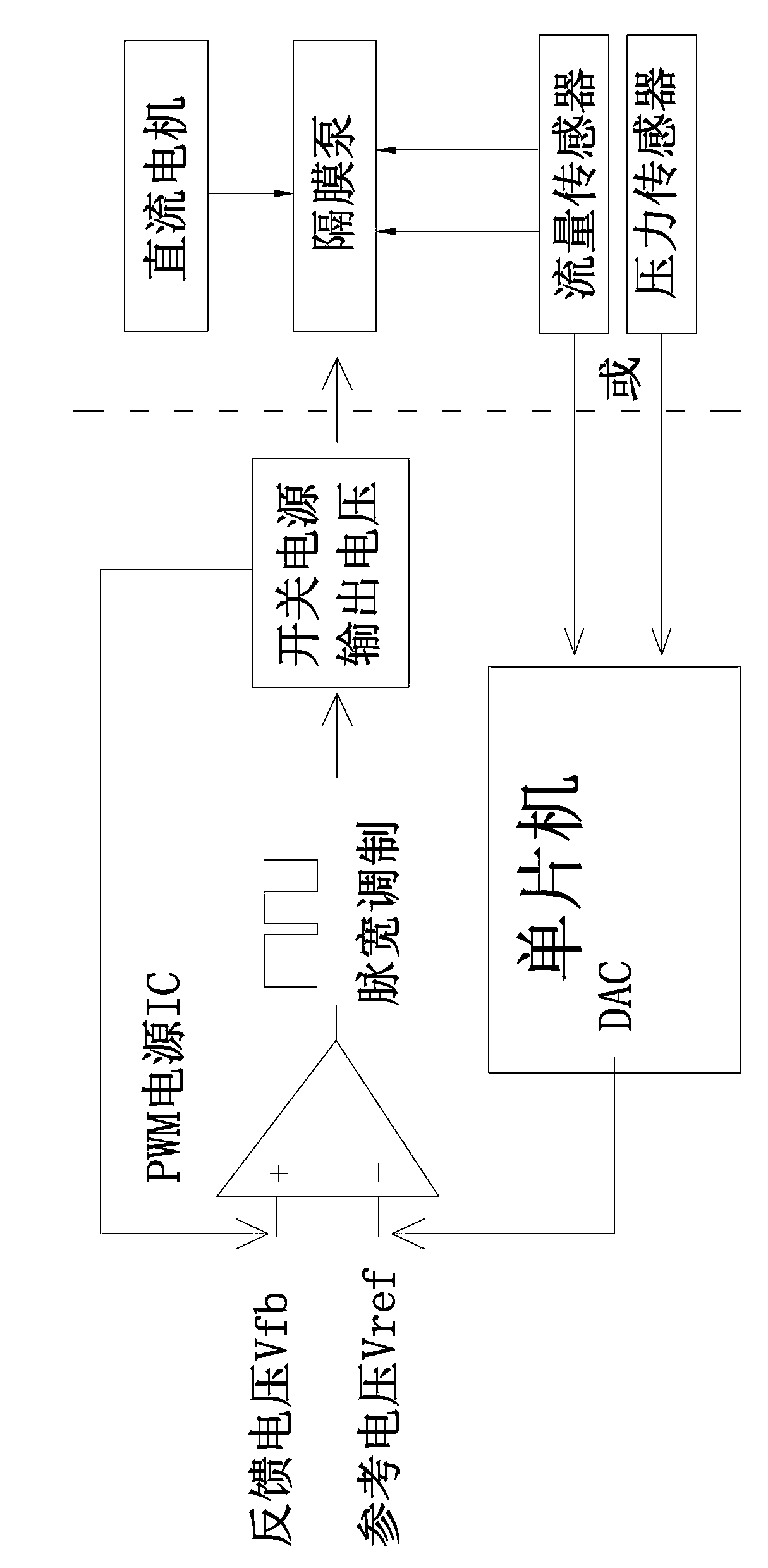

[0023] Such as figure 1 The shown small diaphragm pump simulates the frequency conversion system. The system includes a PWM switching power supply. The PWM switching power supply is respectively connected to a diaphragm pump driven by a DC motor and a single-chip microcomputer with a DAC conversion circuit; a flow sensor is arranged between the diaphragm pump and the single-chip microcomputer. or pressure sensor.

[0024] The output voltage of the PWM power supply IC of the PWM switching power supply is determined by the reference voltage Vref and the feedback voltage Vfb. The reference voltage Vref is provided by the DAC conversion circuit of the microcontroller; the feedback voltage Vfb is taken from the output terminal of the PWM switching power supply. The output end of the PWM switching power supply is connected to the power input end of the diaphragm pump.

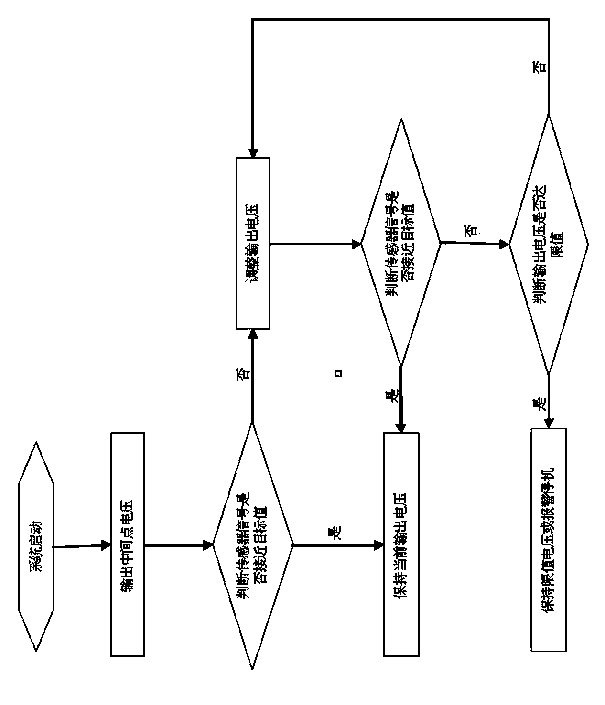

[0025] Such as figure 2 The small diaphragm pump simulation frequency conversion control method shown includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com