Stripping process for diaspore ore

A hydraulic and bauxite technology, which is applied in the dissolution field of diaspore ore, can solve the problems of decreased utilization rate of bauxite, loss of alumina and alkali, increased energy consumption, etc. less, the effect of reducing the amount of red mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

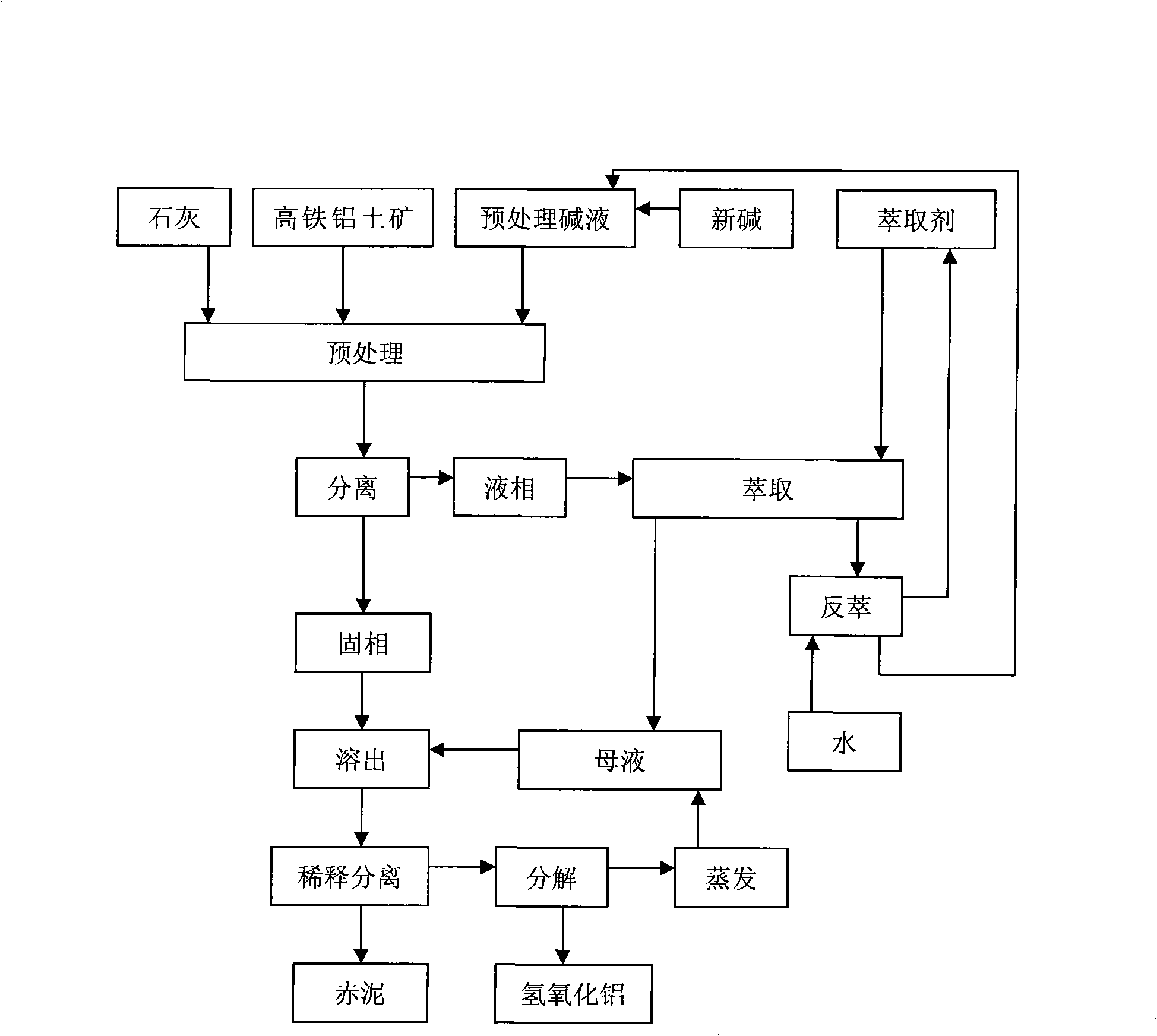

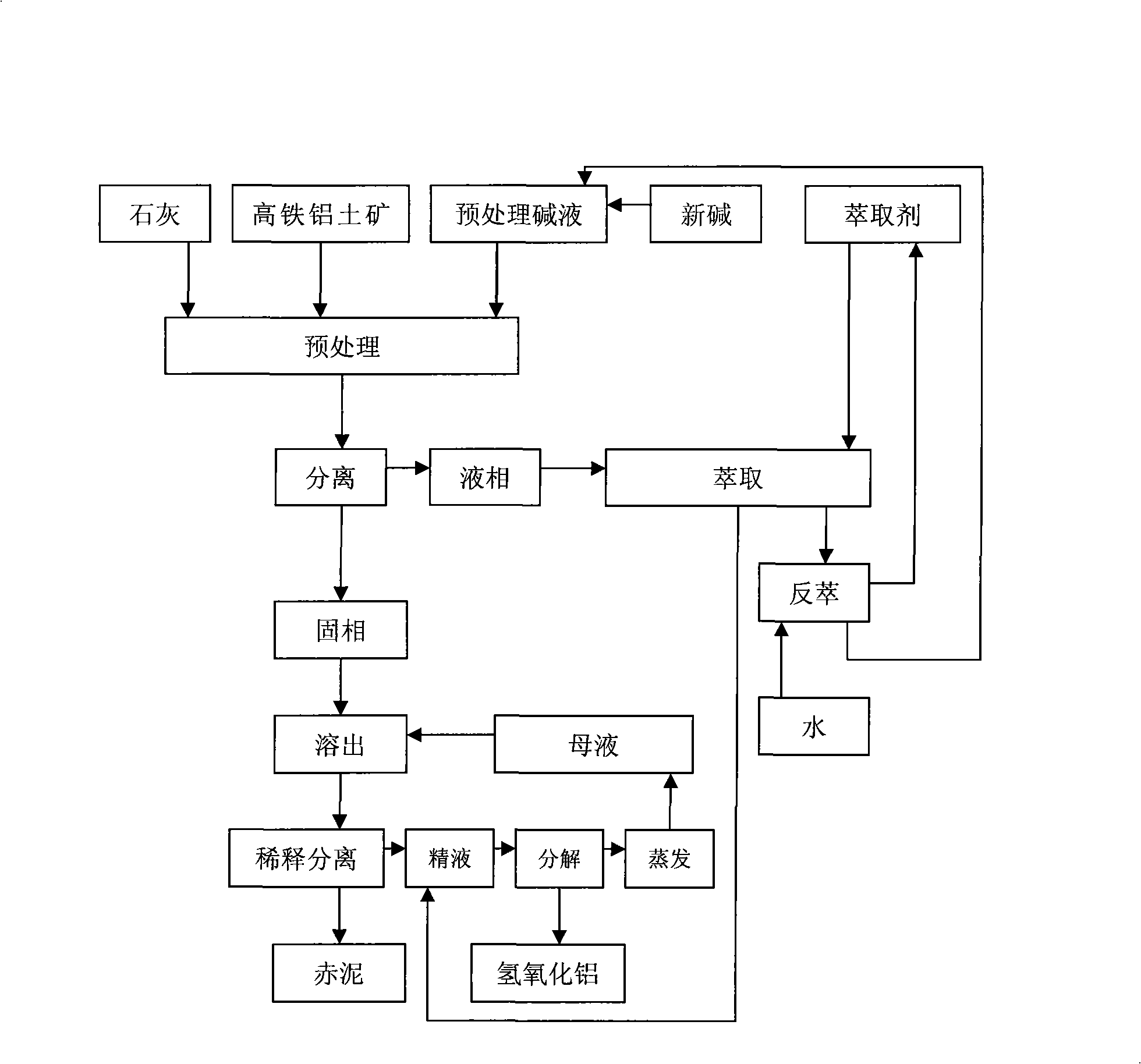

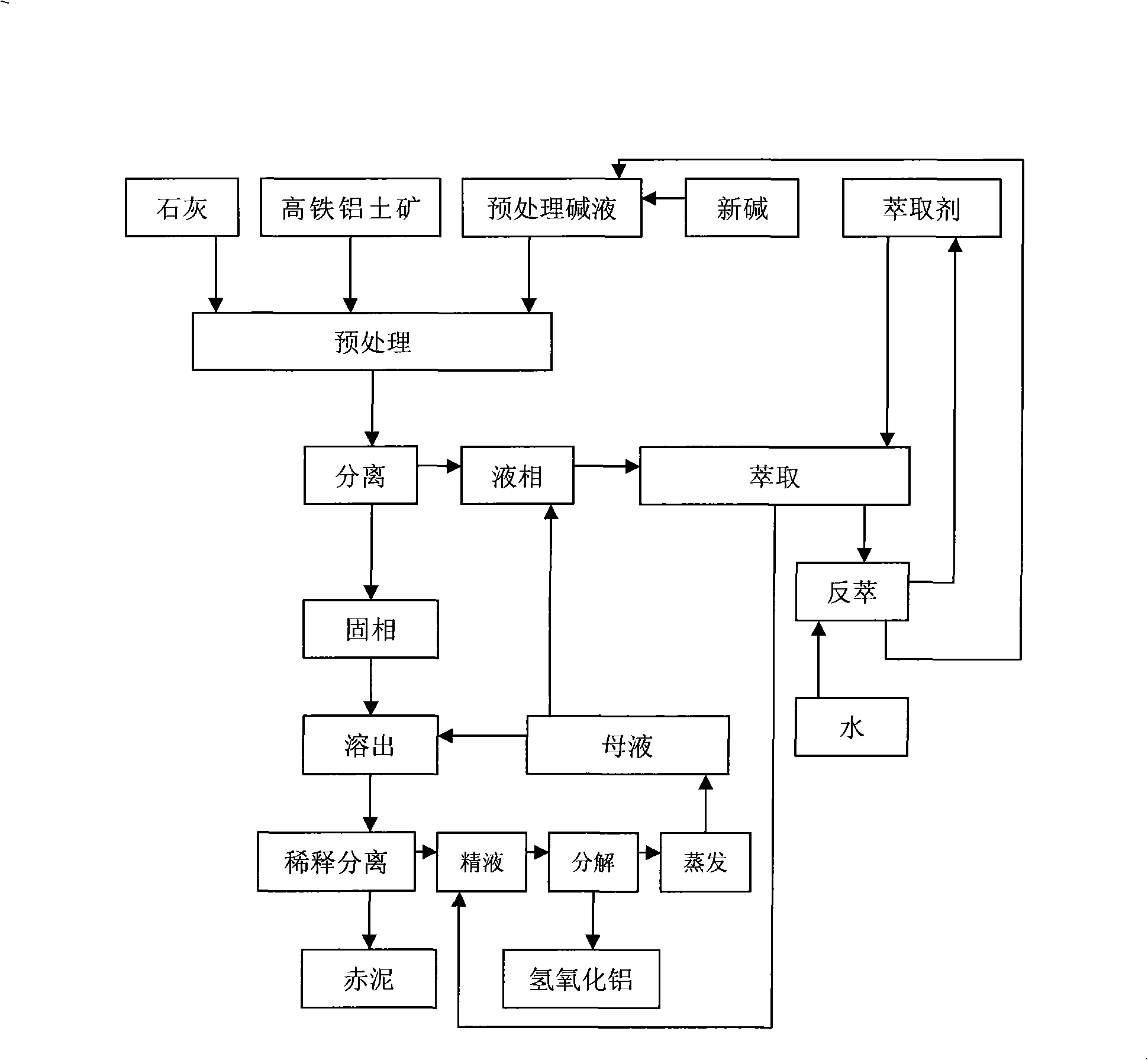

Method used

Image

Examples

Embodiment 1

[0023] in lye N k Under the conditions of 300g / L and alumina concentration of 5g / L, lime and high-iron bauxite (Fe 2 o 3 content is 18%), the amount of lime added is according to C / S (CaO and SiO 2 The mass ratio) is calculated as 2.0, the reaction temperature is 150° C., the reaction time is 2 hours, and liquid-solid separation is carried out after treatment. Add a certain amount of circulating mother liquor to the obtained solid, and dissolve it at 260°C for 45 minutes. The aluminum-silicon ratio of the dissolved red mud is 0.73, and the sodium-silicon ratio is 0.08. For the obtained liquid N k 280g / L, aluminum oxide concentration of 30g / L pretreated lye for liquid-liquid extraction, that is, use fatty alcohol as the extractant to extract sodium hydroxide from the liquid, and then use water as the stripping agent to obtain N k The lye with a concentration of 300g / L and an alumina concentration of 5.5g / L can be used to pretreat the next batch of bauxite. Raffinate causti...

Embodiment 2

[0025] in lye N k Under the conditions of 200g / L and alumina concentration of 3g / L, lime and high iron bauxite (Fe 2 o 3 Content is 16%), the amount of lime added is according to C / S (CaO and SiO 2 The mass ratio) is calculated as 2.5, the reaction temperature is 140°C, and the reaction time is 2 hours. After the treatment, the liquid-solid separation is carried out, and a certain amount of circulating mother liquor is added to the obtained solid, and the aluminum silicon of the red mud is dissolved at 260°C for 60 minutes. The ratio is 0.44 and the ratio of sodium to silicon is 0.04. For the obtained liquid N k 185g / L, aluminum oxide concentration of 20g / L pretreated lye for liquid-liquid extraction, that is, use alkylphenol as extractant to extract sodium hydroxide from the liquid, and then use water as stripping agent to obtain N kThe lye with a concentration of 200g / L and an alumina concentration of 3g / L can be used to pretreat the next batch of bauxite. Raffinate cau...

Embodiment 3

[0027] in lye N k Under the conditions of 400g / L and alumina concentration of 10g / L, lime and high-iron bauxite are added according to the solid content of 300g / L, and the amount of lime added is based on C / S (CaO and SiO 2 The mass ratio) is calculated as 3.0, the reaction temperature is 80°C, and the reaction time is 12 hours. After the treatment, the liquid-solid separation is carried out, and a certain amount of circulating mother liquor is added to the obtained solid, and the aluminum silicon of the red mud is dissolved at 280°C for 30 minutes. The ratio is 0.54, and the ratio of sodium to silicon is 0.03. For the obtained liquid N k 380g / L, aluminum oxide concentration of 60g / L pretreated lye for liquid-liquid extraction, that is, use fatty alcohol as an extractant to extract sodium hydroxide from the liquid, and then use water as a stripping agent to obtain N k The lye with a concentration of 400g / L and an alumina concentration of 10g / L can be used to pretreat the nex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com