Expansive soil foundation structure containing ballastless track roadbed and construction method

A ballastless track and construction method technology, applied in the direction of infrastructure engineering, roads, tracks, etc., can solve the problems of shrinkage deformation, expansive soil foundation deformation, etc., and achieve the effect of reducing uplift deformation and saving engineering investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

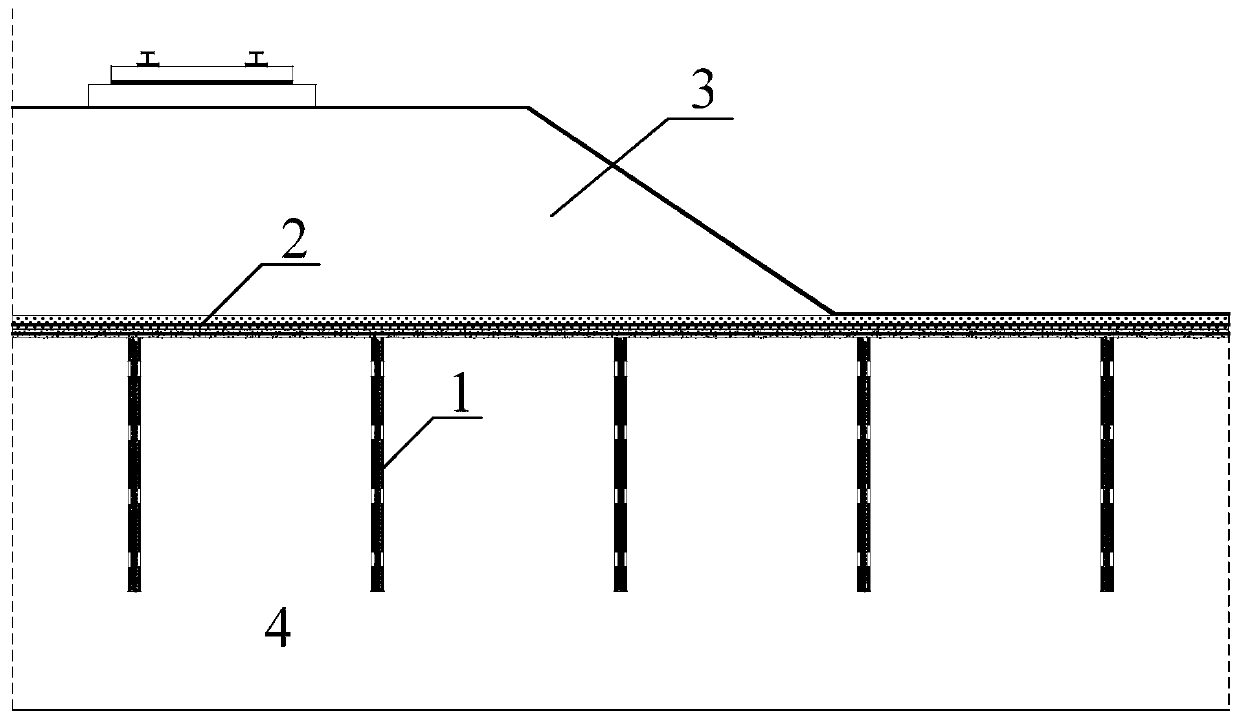

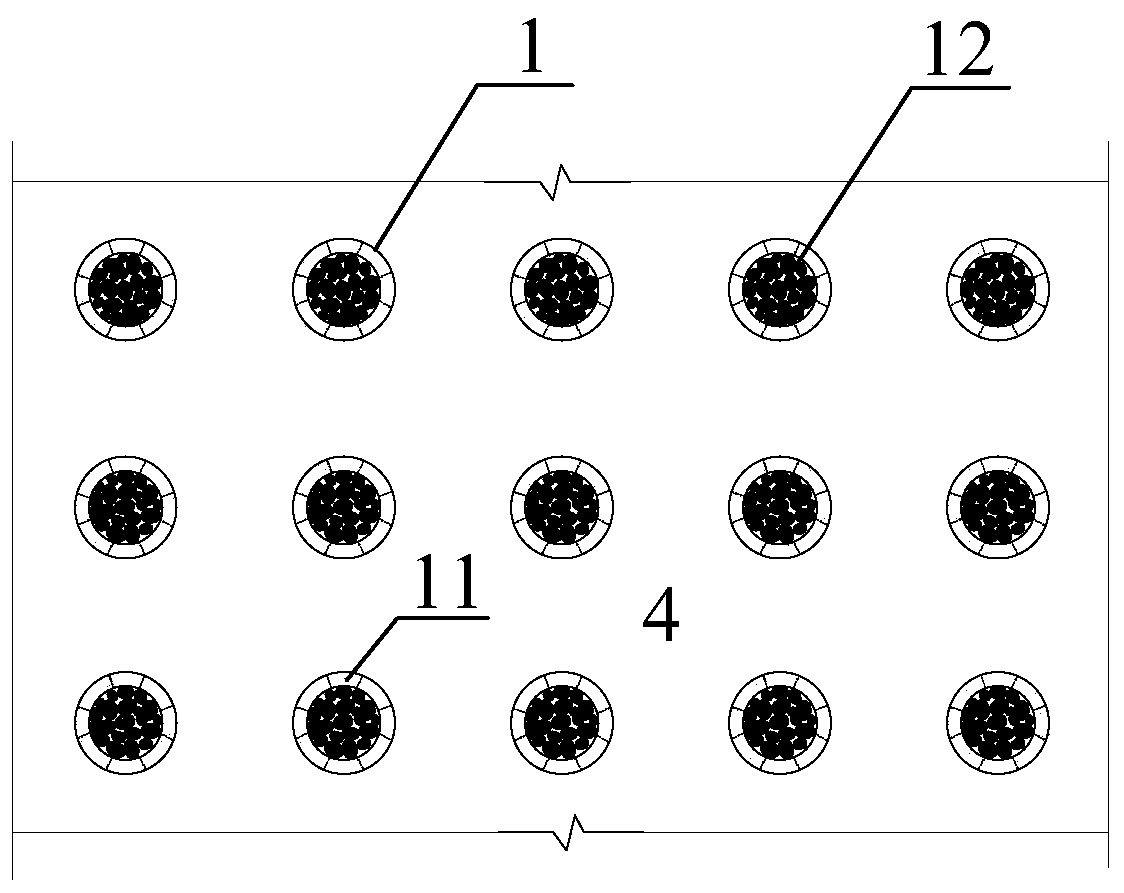

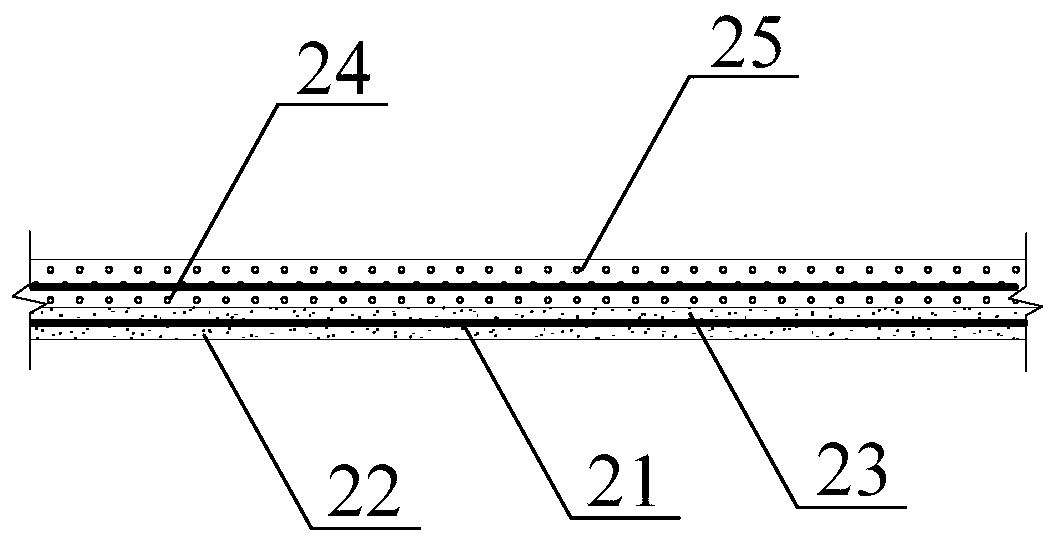

[0033] refer to figure 1 , figure 2 , Figure 4, an expansive soil foundation structure containing a ballastless track subgrade of the present invention, including a porous pipe pile 1, an expansive soil foundation 4, a geosynthetic material reinforced cushion 2 and a ballastless track subgrade 3. The porous pipe pile 1 is composed of a hollow porous pile body 11 and waste tire rubber particles as an elastomer material 12 . The hollow porous pile body 11 of the porous pipe pile 1 is composed of concrete and embedded steel bars. The interior of the pile body is hollow, and a series of radial through holes 13 are arranged at intervals along the pile body, that is, the diameter of each porous pipe pile. The radial through holes are evenly spaced along the pile circumferential direction; the radial through holes on each porous pipe pile are also uniformly spaced along the pile length direction. The interior of the porous pipe pile 1 is densely filled with waste tire rubber par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com