Material composite processing equipment

A composite processing and equipment technology, applied in the field of material composite processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

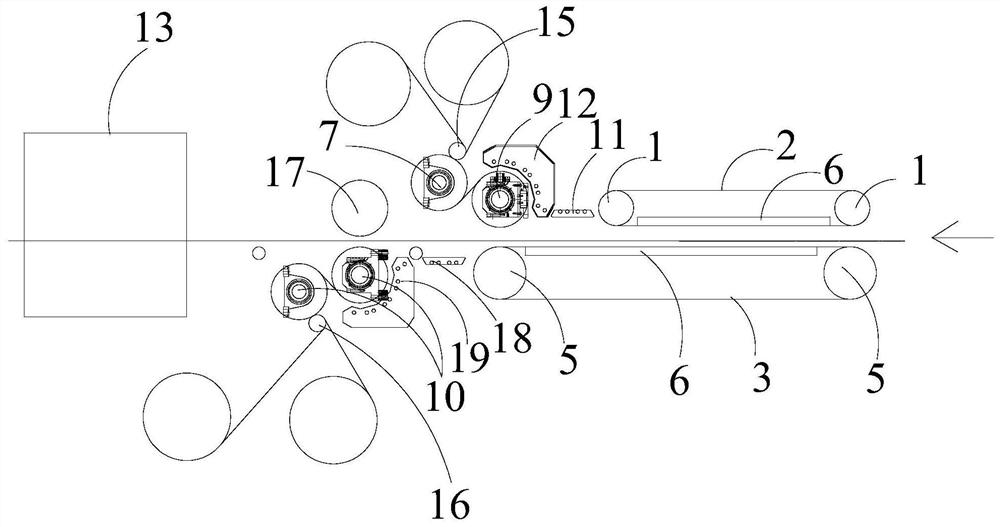

[0033] Such as figure 1 As shown, this embodiment provides a composite processing equipment for materials, including: a first-stage compound mechanism for compounding the first surface layer and the upper surface of the core layer arranged in sequence along the material conveying direction and for compounding the first surface layer The second-level composite mechanism for compounding the lower surface of the second surface layer and the core layer; that is to say, the second-level composite mechanism is located downstream of the first-level composite mechanism, and enters after the upper surface of the core layer completes the composite process with the first surface layer. The secondary composite mechanism performs the composite process of the lower surface of the core layer and the second surface layer.

[0034] In detail, the primary composite mechanism includes a core layer preheating assembly suitable for preheating the upper surface and the lower surface of the core lay...

Embodiment 2

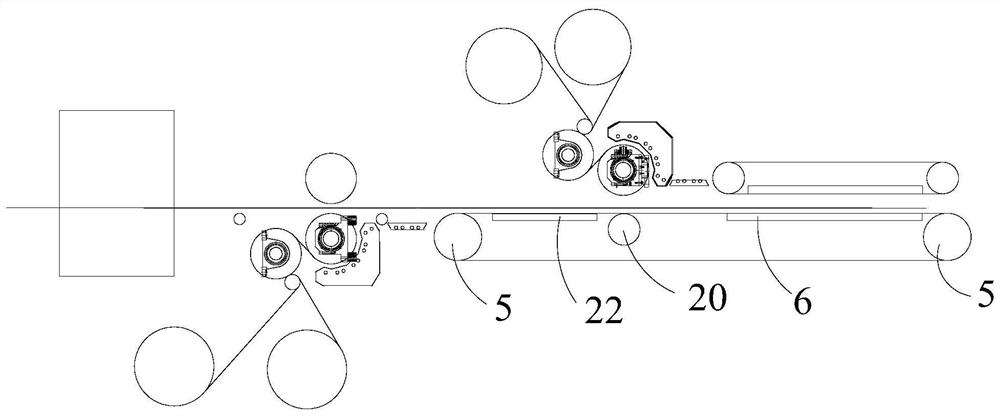

[0052] Such as figure 2As shown, the composite material processing equipment provided in this embodiment has the same general structure as the composite material processing equipment in Embodiment 1, the difference is that the composite material processing equipment in this embodiment also includes a pair of lower drive rollers 5 in the lower annular preheating structure A pressing roll 20 is added between them, and the pressing roll 20 is located directly below the No. 2 preheating roll 9 .

[0053] It should also be noted that the length of the lower annular preheating belt 3 of the present embodiment is that the lower annular preheating belt 3 of the present embodiment extends to the downstream of the first-level composite mechanism. For the composite between the upper surface and the first surface layer, the secondary composite mechanism starts to perform composite processing on the lower surface of the core layer and the second surface layer. Therefore, in order to effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com