Multifunctional paper-surface gypsum board production device

A technology for paper-faced gypsum board and production equipment, which is applied in cleaning equipment, transportation and packaging, and ceramic molding workshops. Concave-convex deformation, the effect of reducing the number of contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

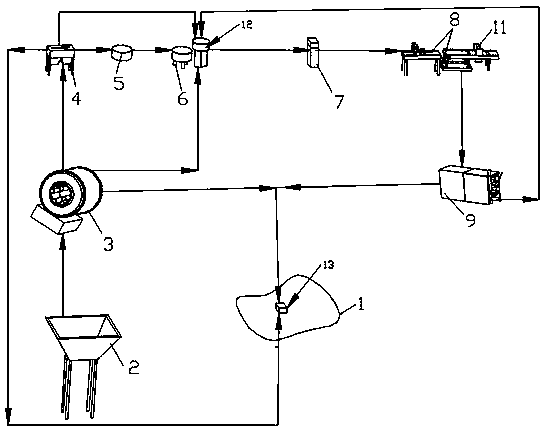

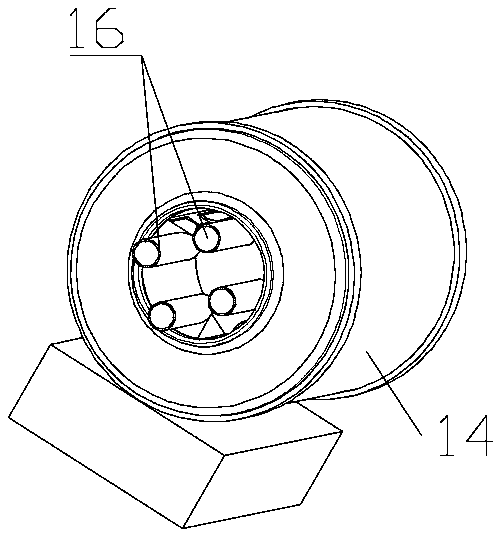

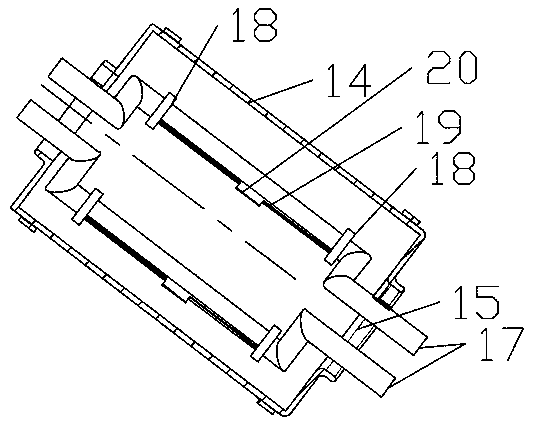

[0036] Example 1. If figure 1 As shown, a multi-functional paper-faced gypsum board production device includes a material field 1, a storage hopper 2, a material drying device 3, a fluidized bed furnace 4, a grinding device 5, a batching device 6, and a gypsum board extrusion molding stick connected in sequence. Paper device 7, transmission frame 8 and baking room 9, more than one endless conveyor belt 10 that is provided with on the transmission frame 8, is provided with cutting machine 11 at the junction of wherein two circulation conveyor belts 10, is all provided with on the transmission frame 8 The rollers are provided with a support plate 36 in contact with the inner surface of the endless conveyor belt 10 between the rollers, and horizontal plates 37 are arranged on the left and right sides of the cutting device. The upper surface is horizontal; the material drying device 3, the fluidized fluidized furnace 4 and the baking room 9 are respectively provided with a steam h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com