Golf ball wood head and manufacture method thereof

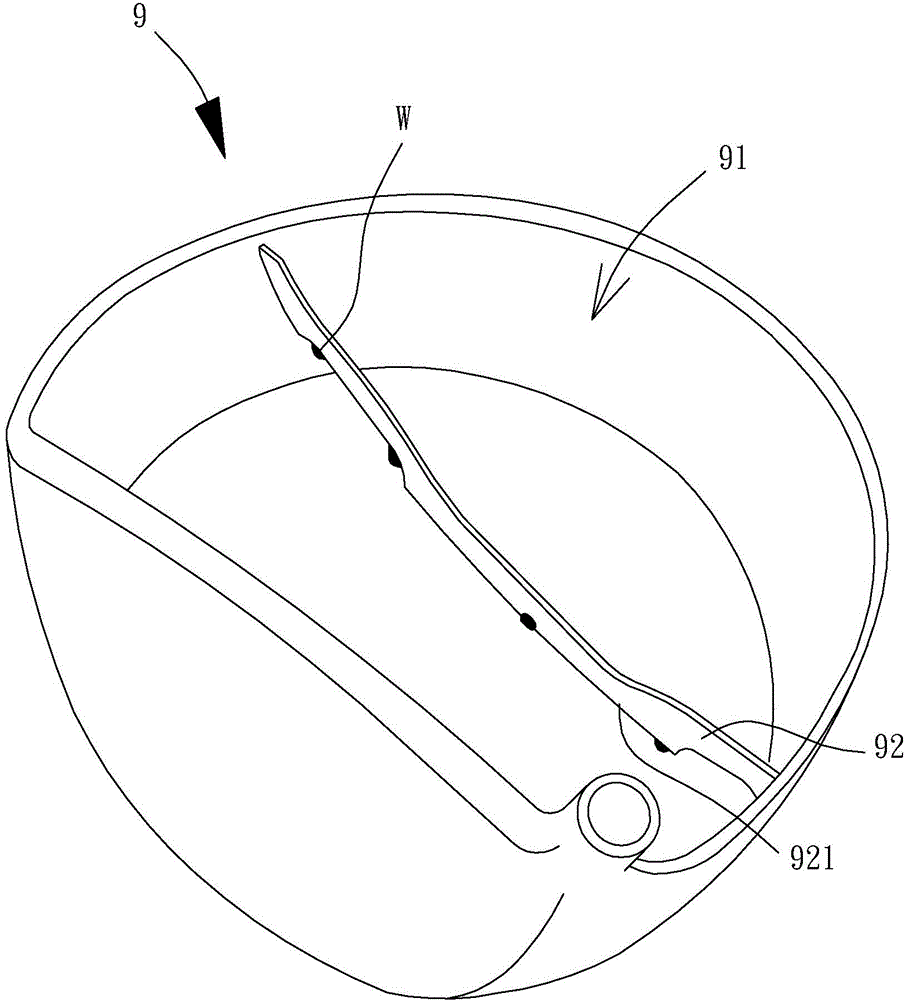

A golf ball and a manufacturing method technology, applied to golf balls, golf clubs, sports accessories, etc., can solve the problems of uneven deformation of the ball head body 9, small contact area, lowering the yield rate of golf wood head products, etc. The effect of reducing uneven deformation, improving structural strength, and maintaining yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0034] In the manufacturing method of the golf wood club head of the present invention, a reinforcing member 1 is arranged inside a golf wood club head to slow down the impact of external force on the golf wood club head and improve the structural strength of the golf wood club head.

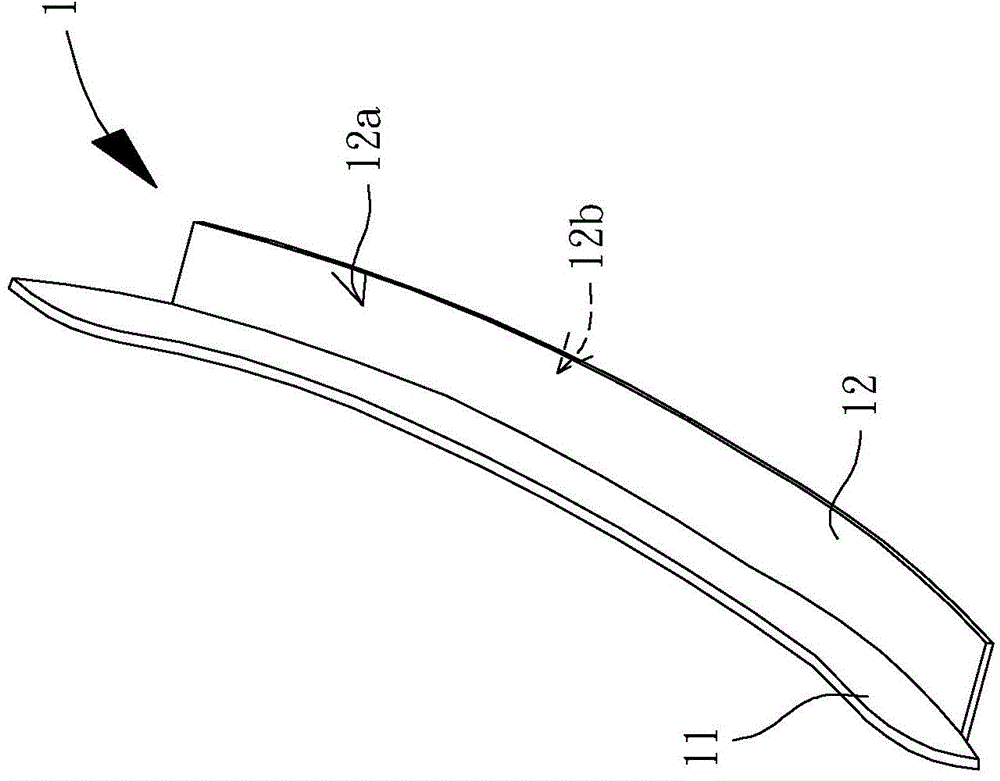

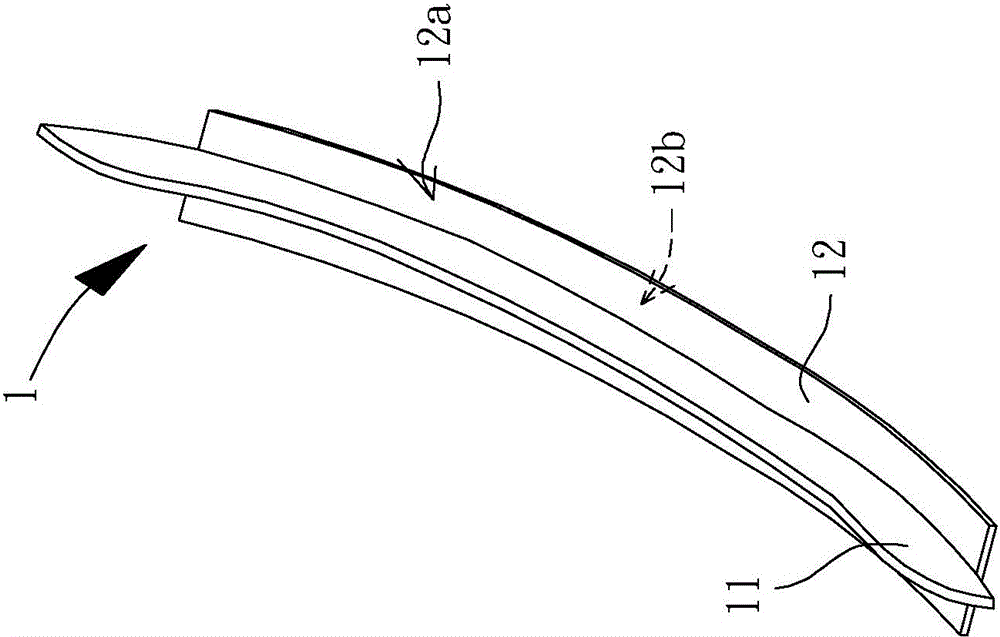

[0035] Please refer to figure 2 and 3 As shown, the reinforcement 1 includes a rib 11 and a spacer 12. The rib 11 is a long strip with opposite side edges and opposite end edges, and the opposite end edges can contact the golf ball. For the wooden club head, the spacer 12 is also a long strip. In addition to having opposite side edges, it also has an opposite joint surface 12a and a welding surface 12b, and preferably, the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com