Telescopic compensation interface for vacuum transportation pipeline

A pipeline and transportation technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/pipes, pipe components, etc., which can solve the problem of sleeve compensator leakage, inconvenience in laying tracks, and unsuitable displacement of vacuum transportation pipelines. Compensation and other issues to achieve the effect of low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

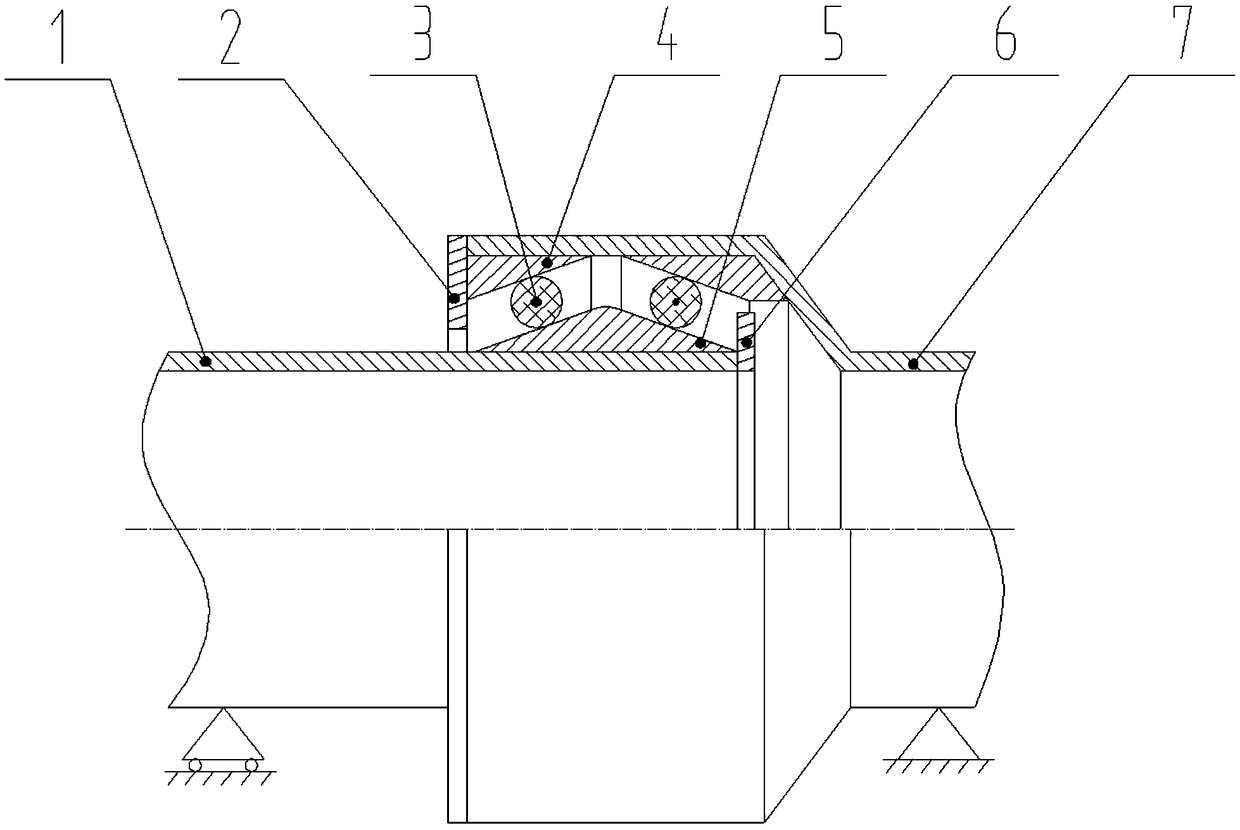

[0021] The straight end 1 of the pipeline is made of steel, which can be ordinary carbon steel, stainless steel or weathering steel. Its outer side is welded with a wedge-shaped ring 5 with a public face. The cross-section of this wedge-shaped ring is triangular. Seen from the cross-section, the two wedge-shaped faces are connected together and have a common intersection line. The surface of the wedge face needs to be smooth enough to facilitate sealing. The pipe socket end 7 is made of the same material as the pipe straight end 1, and the nested part with the pipe straight end 1 needs to be larger than the diameter of the pipe straight end 1, and there are two female surface wedge rings 4 fixed inside the pipe end, each A female wedge-shaped ring has a wedge-shaped surface, and two wedge-shaped surfaces of the male wedge-shaped ring 5 form a group of "V"-shaped ring grooves. Elastic sealing ring 3 is installed on both sides in this " V " shape ring groove. The end of the sm...

Embodiment 2

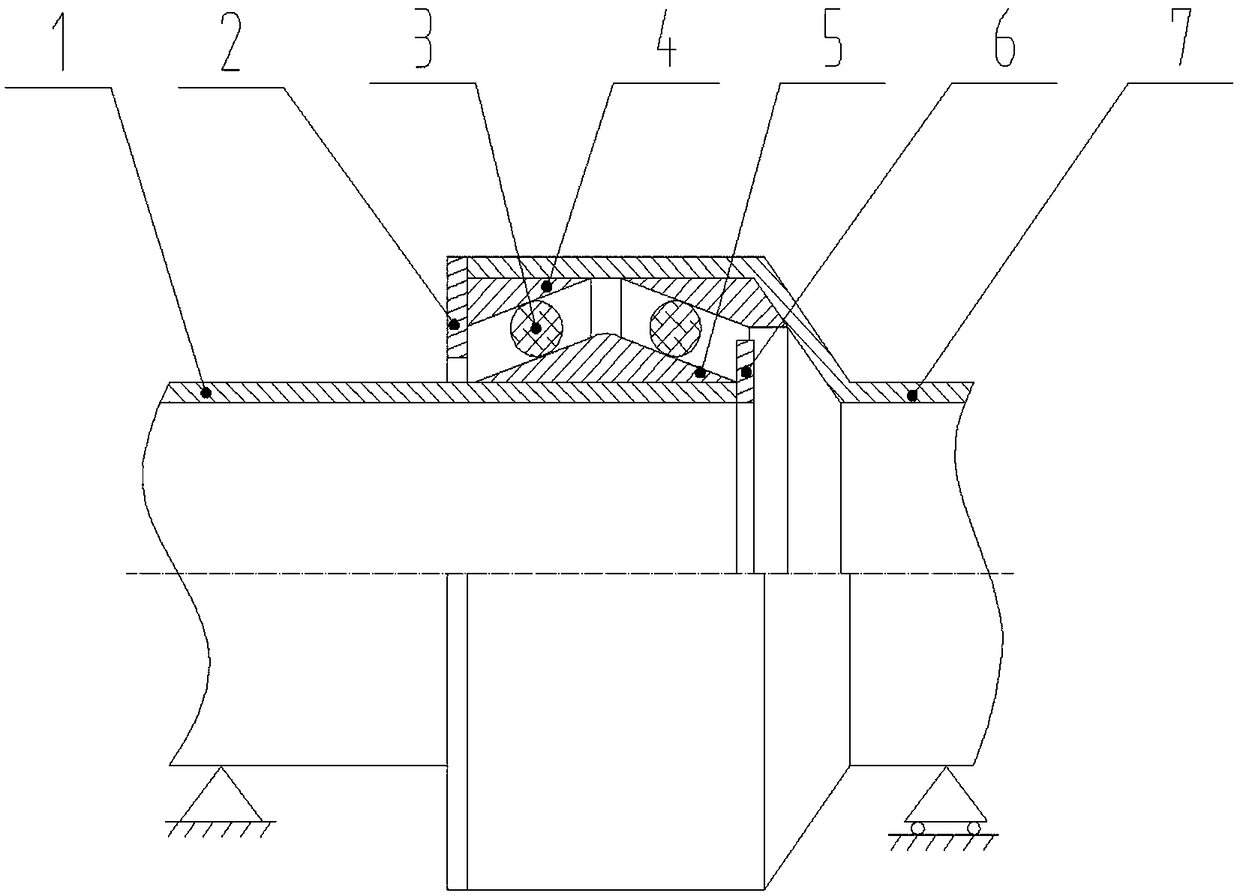

[0025] attached image 3 represents this example.

[0026] This embodiment is also composed of a pipe straight end 1 and a pipe socket end 7. The difference from Embodiment 1 is mainly that the wedge-shaped ring 5 on the public surface and the pipe straight end 1 are an integrated part instead of multiple Composition of parts; the wedge-shaped ring 4 on the female surface and the socket end 7 of the pipe are also one part, rather than composed of multiple parts. The two wedge-shaped surfaces of the wedge-shaped ring 5 on the male surface are not connected together, and there is no common line of intersection, while the two wedge-shaped surfaces of the wedge-shaped ring 4 on the female surface are connected together, and there is a common line of intersection. The elastic sealing ring 3 is also in the "V" ring groove formed by the wedge ring 4 on the female surface and the wedge ring 5 on the male surface, and cannot come out due to the limitation of the straight end baffle 6 ...

Embodiment 3

[0029] attached Figure 4 represents this example.

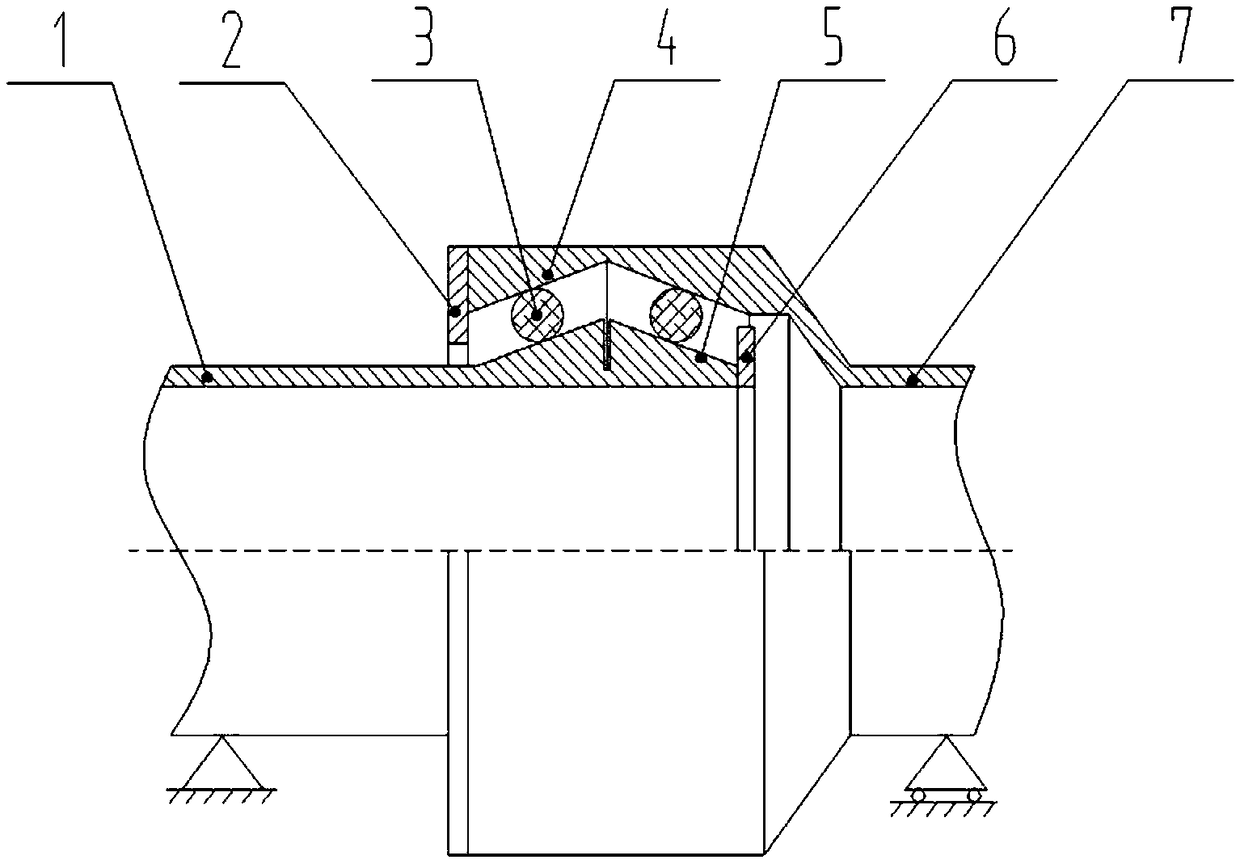

[0030] Embodiment 3 is basically the same as Embodiment 1, the difference is that multiple sets of wedge-shaped rings 4 on the female surface, wedge-shaped rings on the male surface 5 and elastic sealing rings 3 are arranged along the axial direction of the pipeline to form multiple sets of "V"-shaped ring grooves and elastic sealing rings. The sealing structure of ring 3. Its sealing principle is completely consistent with the implementation process, but the reliability of the sealing is enhanced by increasing the redundancy of the structure.

[0031] Implementation process is with reference to embodiment 1, both are basically the same. It's just that when one set of seals fails, the pipe remains sealed if the other set doesn't fail at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com