Temperature sensing type spraying and filling construction joint waterproof structure and construction method thereof

A waterproof structure and construction method technology, which is applied in the direction of building components, building structures, building insulation materials, etc., can solve the problems of cost increase, achieve the effects of reducing pollution, prolonging the seepage path, and reducing the probability of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

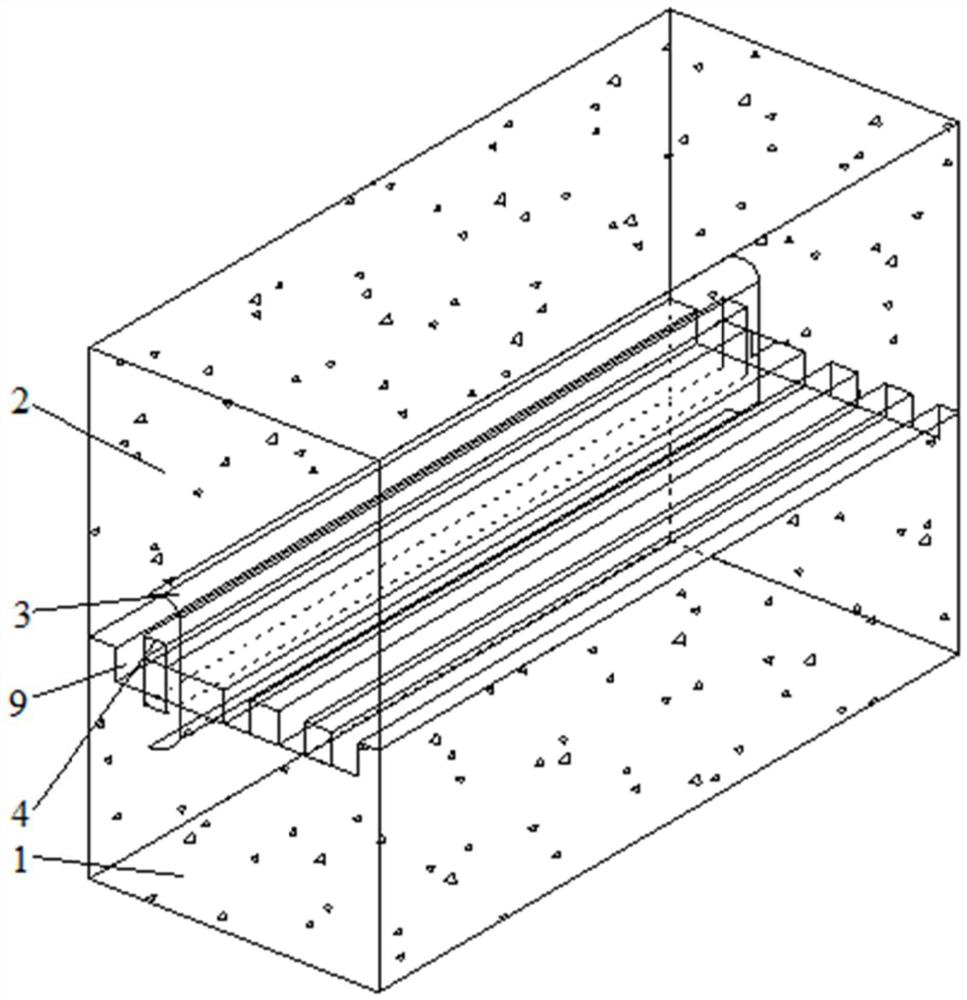

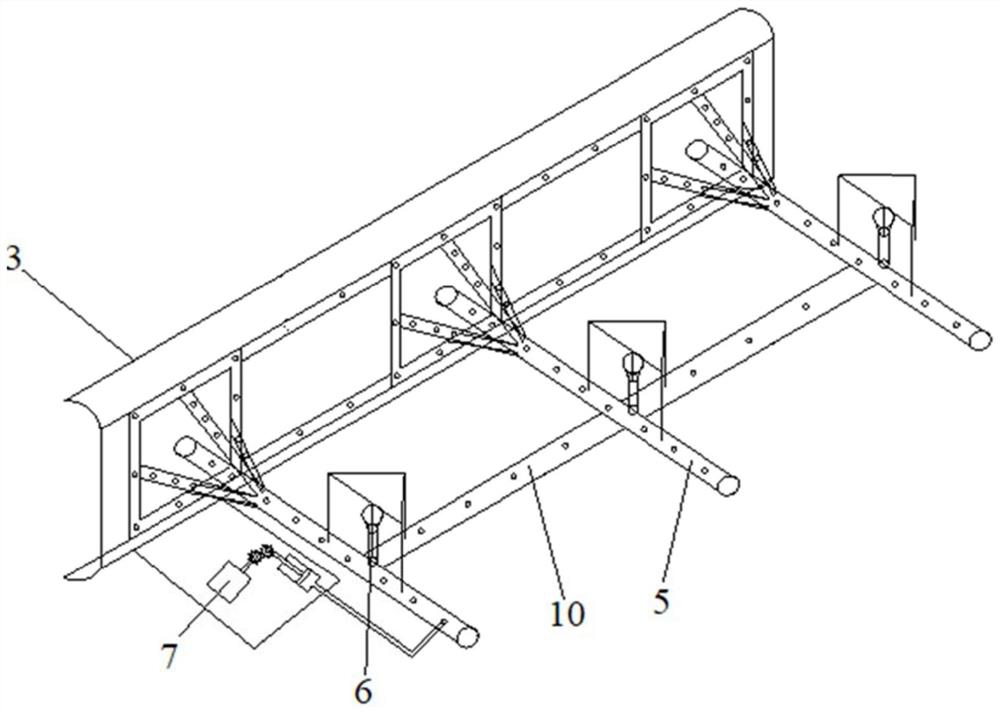

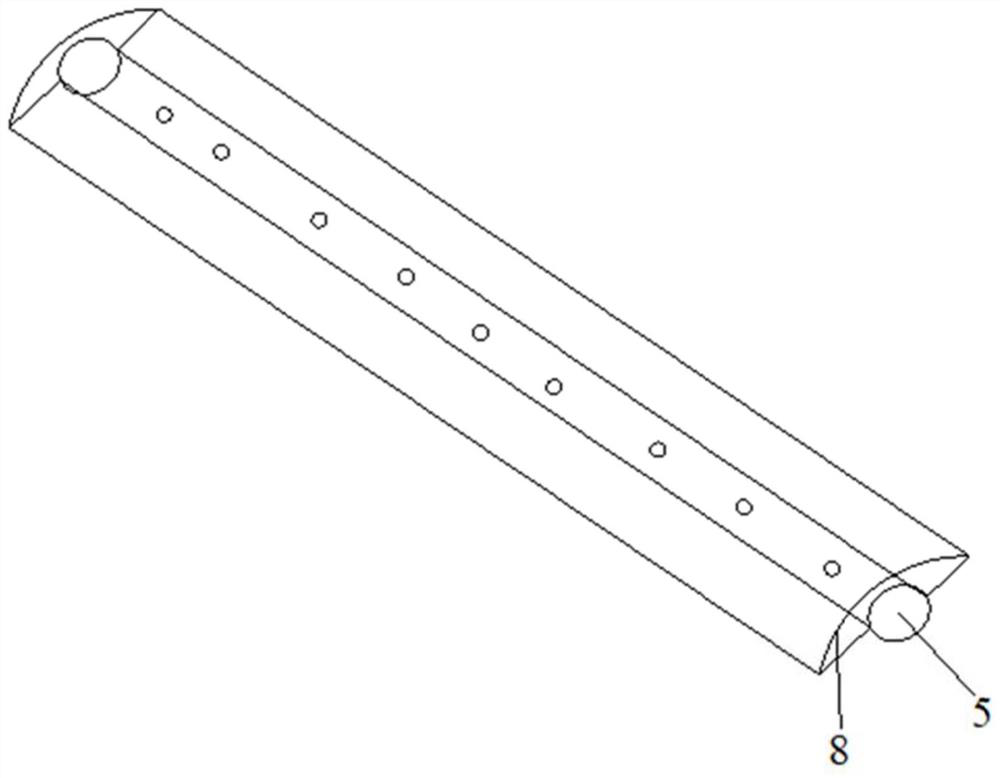

[0030] see Figure 1 to Figure 4 As shown in the figure, a temperature-sensitive spray-filled construction joint waterproof structure provided by the present invention includes a lower wall 1, an upper wall 2, a water-stop steel plate 3, a water-swellable water-stop strip 4, a paint pipe 5, and a temperature sensor 6 , press 7. Wherein, the lower wall 1 is fixed on the upper end of the upper wall 2, the water-stop steel plate 3 is fixedly connected to the lower wall 1 and the upper wall 2, and the water-swelling water-stop strip 4 is sandwiched between the lower wall 1 and the upper wall 2. In between, a row of water-swellable water-stop strips 4 is attached to the front of the water-stop steel plate 3, and is arranged below the bend of the water-stop steel plate 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com