Preparation method of phenolic resin for refractory material

A technology of phenolic resin and refractory materials, applied in the field of phenolic resin, can solve the problems of poor stability of phenolic resin, low carbon residue, increased cost, etc., achieve high stability, increase carbon residue, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The embodiment of the present invention discloses a preparation method of phenolic resin for refractory materials, comprising:

[0020] Under the action of the basic catalyst, the phenolic compound, the aldehyde compound and o-phenylphenol are polycondensed to obtain the phenolic resin.

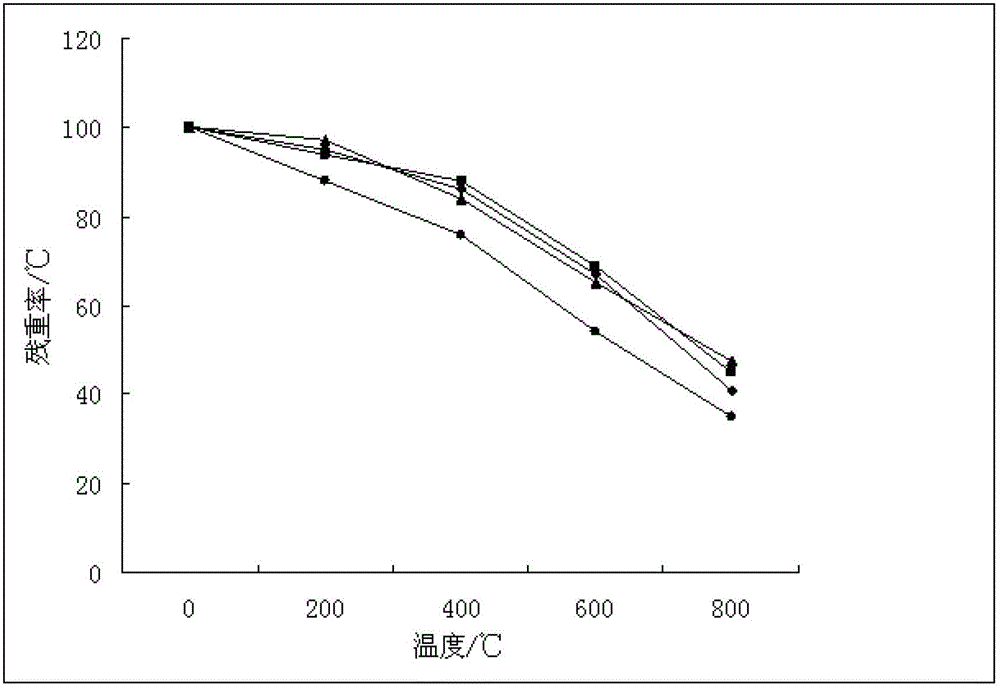

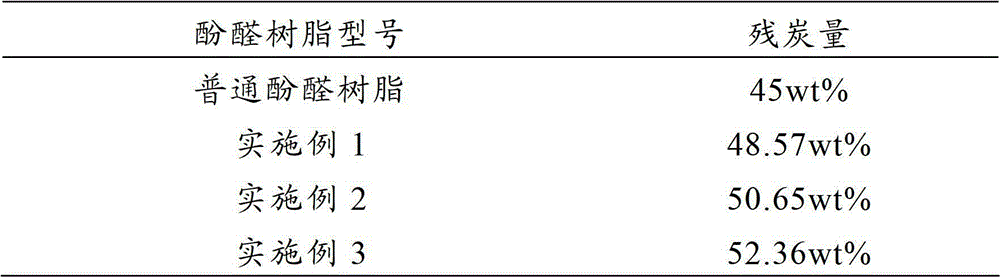

[0021] The present invention synthesizes a phenolic resin containing an aromatic ring by introducing o-phenylphenol into the phenolic resin. Due to the introduction of the aromatic ring, the carbon content of the phenolic resin is increased, and the bond energy of the aromatic ring is higher , The structure is stable, and it is not easy to break during ablation, which increases the amount of carbon residue in the phenolic resin system, so that the phenolic resin has higher stability. On the other hand, since the phenolic hydroxyl group is surrounded by aromatic heterocycles, its water resistance and alkali resistance are greatly improved.

[0022] Since what the present invention prep...

Embodiment 1

[0029] Mix phenol, formaldehyde, and o-phenylphenol at a molar ratio of 1:1.0:0.1, then add ammonia water, stir, and raise the temperature to 60°C at the same time, keep the temperature within this temperature range for 4 hours, and vacuum dehydrate until the water is 5%; add ethylene glycol Alcohol adjusts the viscosity to 3000cp / 25°C.

Embodiment 2

[0031] Mix phenol, formaldehyde, and o-phenylphenol at a molar ratio of 1:1.3:0.5, then add sodium hydroxide, stir, and raise the temperature to 70°C at the same time, keep the temperature within this temperature range for 3 hours, and vacuum dehydrate until the moisture is 6%; add Diethylene glycol adjusts the viscosity to 5000cp / 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com