Preparation method for preparing biphenyl and o-phenylphenol by hydrofining industrial dibenzofuran

A technology for o-phenylphenol and industrial oxyfluorene is applied in the field of industrial oxyfluorene hydrorefining to prepare biphenyl and o-phenylphenol, and can solve the problems of tediousness, many process steps and the like, and achieves simple operation, ultra-high selectivity, high The effect of good economic benefits and industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

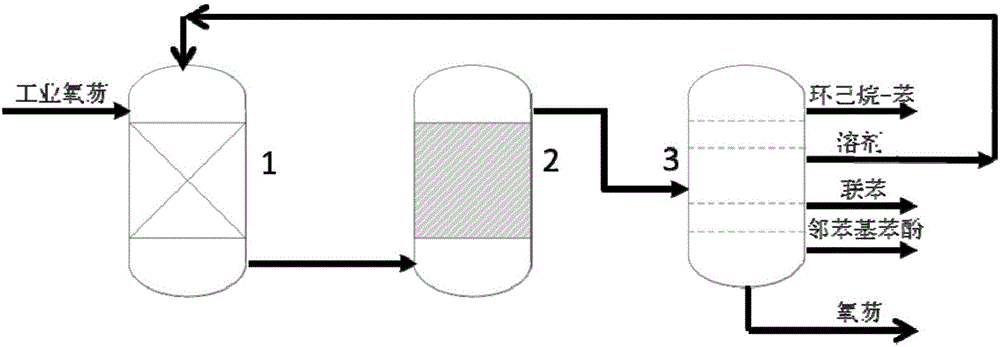

Image

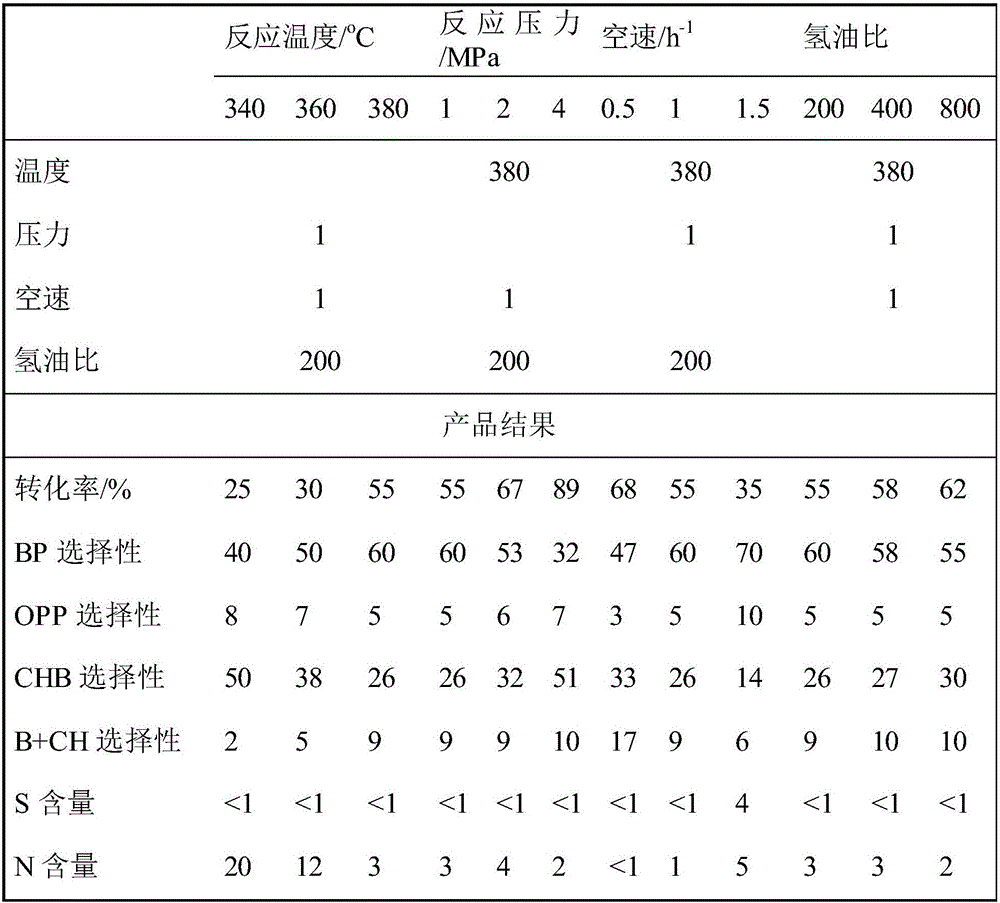

Examples

Embodiment 1

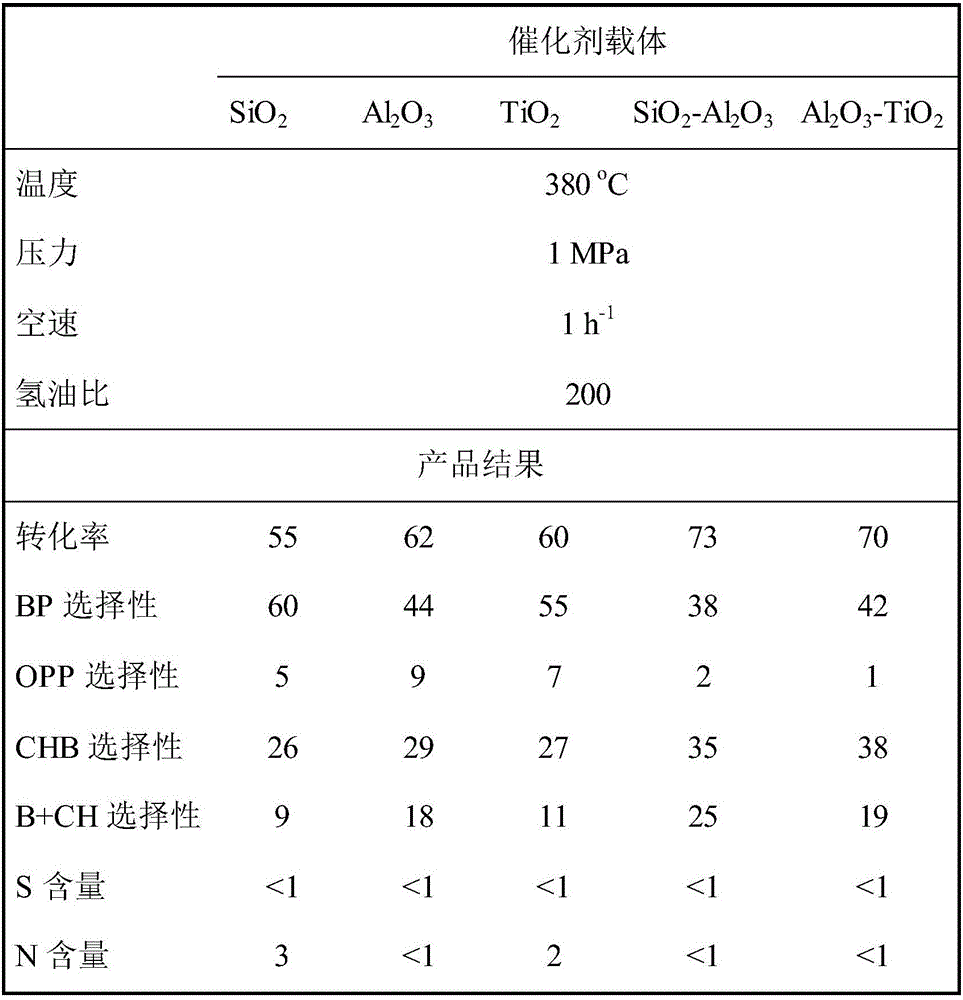

[0014] Example 1: The supported CoMo catalyst is prepared by co-precipitation method, and its carrier is SiO 2 、Al 2 o 3 、TiO 2 , SiO 2 -Al 2 o 3 or Al 2 o 3 -TiO 2 , the specific preparation process is: dissolving cobalt nitrate and ammonium molybdate respectively, then adding a complexing agent to the cobalt nitrate solvent, slowly adding ammonium molybdate to form a complex between Co and Mo, adding the carrier to the metal complex Add a precipitating agent to the solution, and the precipitated solid is dried at 180°C. After drying, it is molded and calcined, and the hydrogenation refining catalyst is prepared by reduction. The reduction procedure is: reduce 50ml of catalyst, the hydrogen concentration is 85%, the hydrogen flow rate is 2000ml / min, and the temperature rises The rate is 2°C / min, the temperature is kept at 420°C for 8h, the temperature is naturally lowered, and passivated for later use. Catalysts with different loads can be prepared by changing the ca...

Embodiment 2

[0015] Embodiment 2: On the basis of embodiment 1, prepare 6Co16Mo / SiO 2 、6Co16Mo / Al 2 o 3 、6Co16Mo / TiO 2 、6Co16Mo / SiO 2 -Al 2 o 3 and 6Co16Mo / Al 2 o 3 -TiO 2 catalyst.

Embodiment 3

[0016] Embodiment 3: On the basis of embodiment 1, prepare 6Co16Mo / SiO 2 , the loading amount of metal Co was 6%, and the loading amount of metal Mo was 16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com