A method for recovering and reusing waste lithium ion battery

A lithium-ion battery, waste technology, applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of complicated recycling process, no further innovative use of electrode materials, increased cost of chloride salt, etc. Achieve the effect of simple operation, promoting further application and avoiding the cost of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for recycling waste lithium-ion batteries, specifically comprising the steps of:

[0027] (1) Put the waste lithium battery in a closed box, disassemble it manually, classify the disassembled materials according to the material, and collect the positive electrode sheet, mainly lithium manganate.

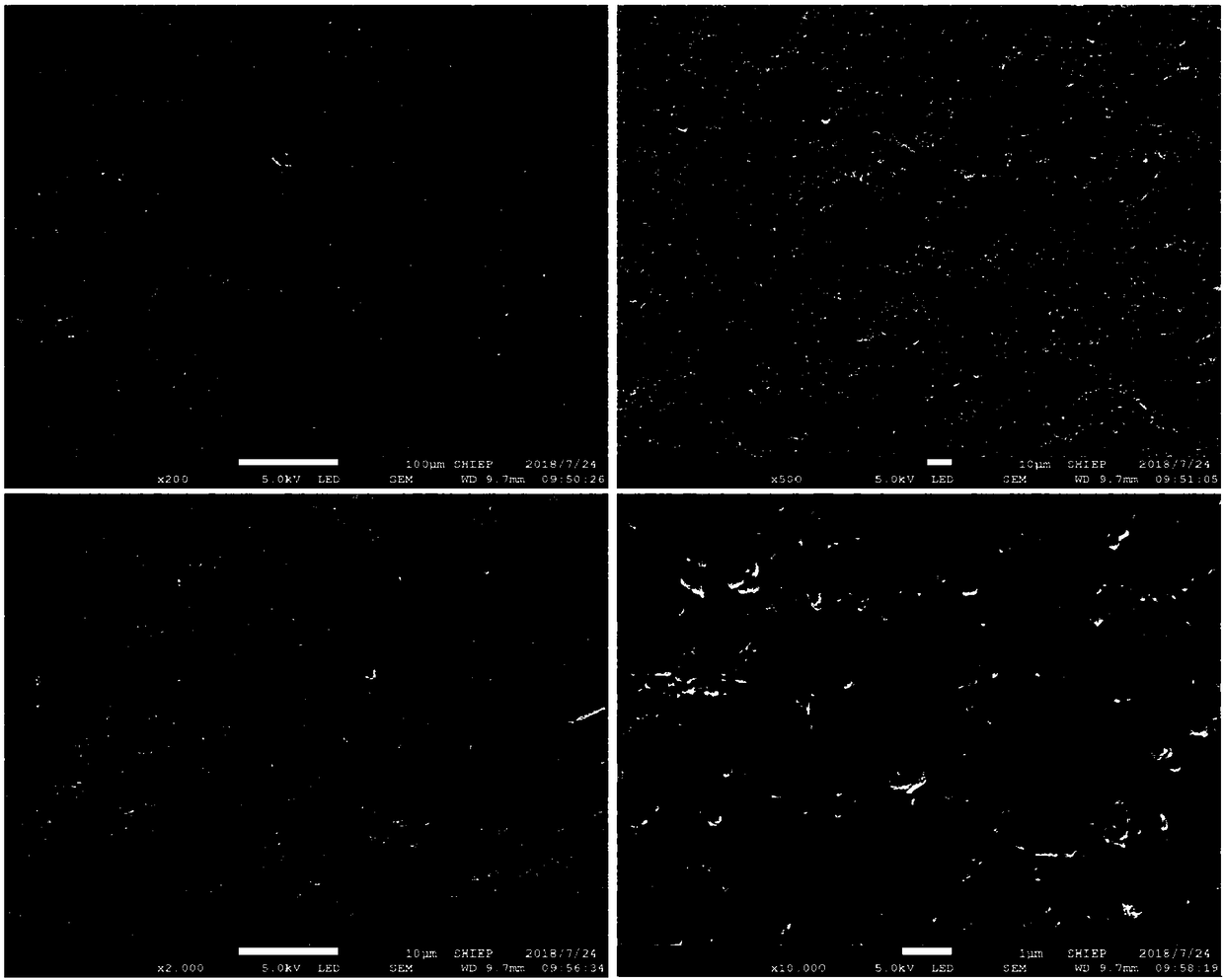

[0028] (2) The collected positive electrode sheet was first soaked in deionized water with a solid-to-liquid ratio of 200 g / L for 30 minutes, and the leachate was collected, and then the positive electrode sheet was washed 3 times with absolute ethanol.

[0029] (3) The cleaned positive electrode sheet was vacuum-dried at a temperature of 60° C. for 12 hours to obtain an active lithium manganate positive electrode sheet.

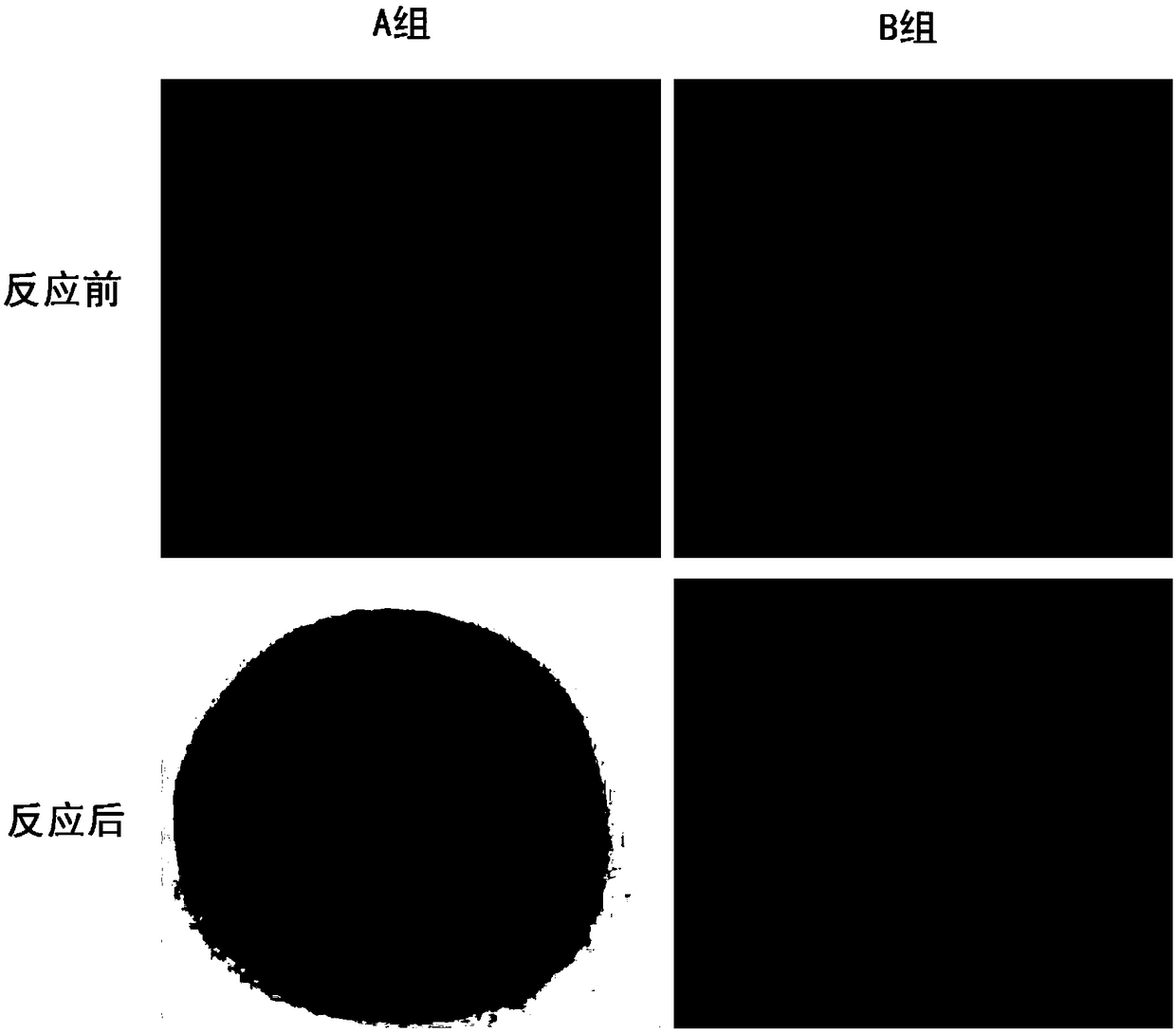

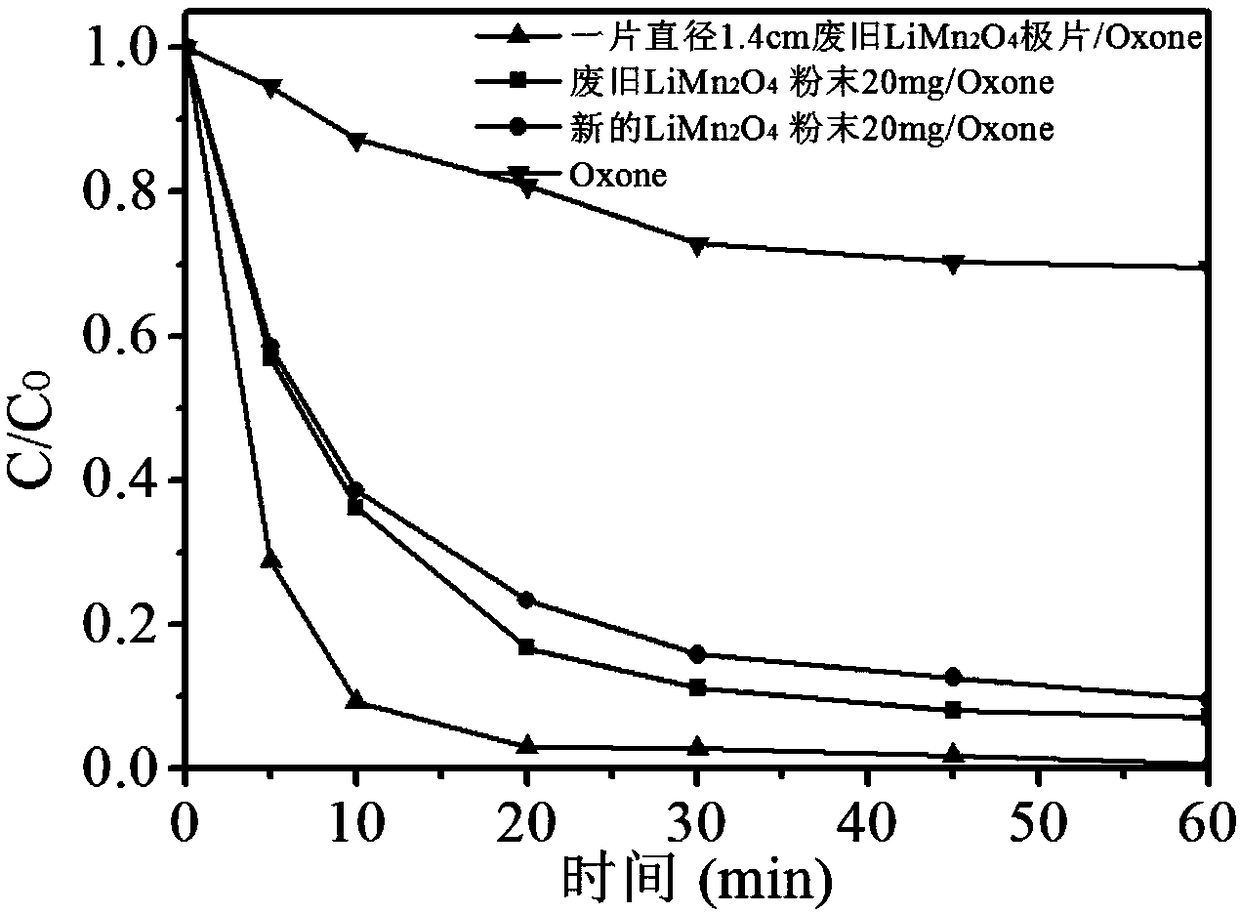

[0030] (4) Take a piece of active lithium manganate positive electrode sheet with a diameter of 1.4cm, add it to a volume of 100ml of o-phenylphenol solution with a pH of 7 and a concentration of 20ppm, and then add 30mg of potassium hydrogen persul...

Embodiment 2

[0035] The active lithium manganate positive plate mainly based on lithium manganate obtained in the examples is used as a heterogeneous catalyst for the catalytic oxidation reaction of advanced oxidation technology based on sulfate radicals to degrade o-phenylphenol wastewater. The specific process as follows:

[0036] Get 100ml concentration and be the ortho-phenylphenol waste water of 20ppm in the beaker of 100ml, add the potassium hydrogen persulfate complex salt of 30mg, then add the positive plate catalyst of a piece of diameter 1.4cm, catalyzer is fixed with perforation in the middle of iron wire. The pH of the solution was adjusted to neutral with 185 mg of disodium hydrogen phosphate and 152 mg of sodium dihydrogen phosphate. Place the beaker bottle on a magnetic stirrer for stirring reaction, take the addition of oxidant as the zero point of the timing, take a sample every once in a while, immediately add an equal volume of methanol to quench, filter with a 0.22um fi...

Embodiment 3

[0042] A method for recycling waste lithium batteries, the following steps are adopted:

[0043] (1) Disassemble the waste lithium-ion battery in an airtight box to obtain an active positive electrode, mainly lithium cobaltate;

[0044] (2) The collected positive electrode sheet is first soaked in deionized water with a solid-to-liquid ratio of 200g / L for 15 minutes, and the leachate is collected, and then the positive electrode sheet is washed 3 times with absolute ethanol;

[0045] (3) Vacuum drying the cleaned positive electrode sheet at a temperature of 60° C. for 12 hours to obtain an active lithium cobaltate positive electrode sheet mainly composed of lithium cobalt oxide;

[0046] (4) Take a piece of active lithium cobaltate positive electrode sheet with a diameter of 1.4cm, add it to 100ml of rhodamine B solution with a pH of 7 and a concentration of 20ppm, and then add 20mg of potassium persulfate compound salt to realize the rhodamine Catalytic degradation of B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com