Preparation method of high-dispersion copper-based catalyst based on non-precious metal

A technology of copper-based catalysts and precious metals, applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high production cost of o-phenylphenol and achieve the goal of preparing The process is simple and easy, the structure is regular, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] One, the preparation of metal oxide catalyst:

[0035] 1. Weigh 20.48g Cu(NO 3 ) 2 ·3H 2 O, 30.42g Mg(NO 3 ) 2 ·6H 2 O and 12.72g Al 2 (NO 3 ) 3 9H 2 O was dissolved in 500 mL of deionized water to prepare mixed salt solution A.

[0036]2. Take 20g NaOH and 53g NaOH 2 CO 3 Dissolve in 500mL deionized water to make mixed alkali solution B.

[0037] 3. Add a certain amount of deionized water to the flask and heat it to the reaction temperature of 60°C. Add solutions A and B to the four-necked flask at a rate of 2.5mL / min under stirring, and keep the mixed solution during the dropping process. The pH of the mixture is about 9.5, and it is vigorously stirred for aging. The temperature condition of the aging treatment is 30-60° C., and the time is 2-4 hours. After the dropwise addition is completed, the aged mixed solution is obtained.

[0038] 4. Transfer the aged mixed solution into a stainless steel hydrothermal reaction kettle for crystallization at 110° C. ...

Embodiment 2

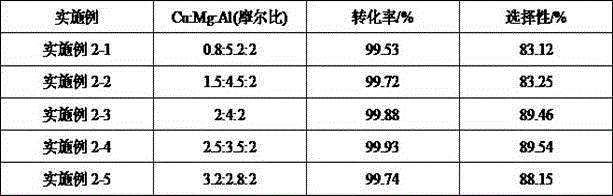

[0047] According to the catalyst preparation method in Example 1, catalysts with different copper-magnesium-aluminum ratios were prepared. Under the same activity evaluation conditions, the results are shown in Table 1 below.

[0048] Table 1 Evaluation results of catalyst activity with different molar ratios of copper, magnesium and aluminum

[0049]

[0050] It can be seen from the above table: according to the catalyst preparation method of Example 1, the copper-based catalysts with different molar ratios have good catalytic performance, and the conversion rate of raw materials is more than 99%. Under normal circumstances, the selectivity to o-phenylphenol can still reach more than 83%.

[0051] Illustrate that the catalyst prepared by this method has higher catalytic activity. When the copper-magnesium-aluminum mol ratio is 2.5:3.5:2, the conversion rate of raw materials reaches 99.93%, the selectivity of the target product o-phenylphenol reaches 89.54%, and the catalyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com