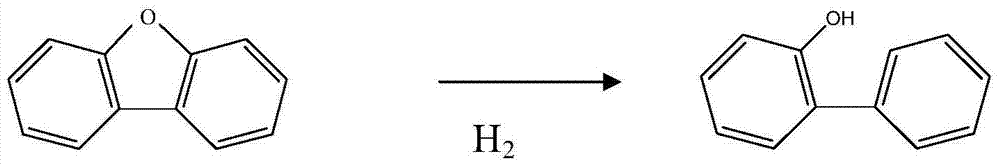

Catalyst composition and preparation method thereof, and method for preparing o-phenylphenol by using catalyst composition

A composition and catalyst technology, which is applied in the preparation of organic compounds, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve problems such as unindustrialization, and achieve large-scale industrial production, easy availability of materials, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Pre-prepared catalyst support γ-Al 2 o 3 : Sieve a certain amount of 40-60 mesh active Al 2 o 3 Granules were calcined in a muffle furnace at 550°C for 4 hours to obtain γ-Al 2 o 3 .

[0040] Preparation of Pt / γ-Al by Equal Volume Impregnation 2 o 3 Catalyst: First prepare an aqueous solution of chloroplatinic acid, dissolve 1.0 g of solid chloroplatinic acid with deionized water, set the volume in a 25 ml brown volumetric flask, and refrigerate for later use. Weigh 10g γ-Al 2 o 3 For the carrier, measure 13 ml of chloroplatinic acid aqueous solution (calculated based on the measured saturated water absorption of 1.3 ml / g) containing Pt element as an equivalent of 2% of the mass of the carrier as the impregnating solution. Add impregnation droplet to γ-Al 2 o 3 Carrier, soak overnight at room temperature.

[0041] Catalyst calcination and active material reduction: The impregnated catalyst was calcined in a muffle furnace at 450°C for 4 hours to obtain the f...

Embodiment 2

[0046] The selected carrier is θ-Al 2 o 3 , the preparation process is consistent with that of Example 1, except that the calcination temperature is different, which is 950° C. for 4 hours.

[0047] The catalyst also adopts the same volume impregnation method to load the active components, except for the specific content, the impregnation process is the same as that of Example 1.

[0048] Catalyst finalization adopts roasting method, is consistent with embodiment 1, finally makes 2%Pt / θ-Al 2 o 3 catalyst composition.

[0049] The evaluation experiment adopted the same evaluation method and conditions as in Example 1, and the results were obtained: the average conversion rate of DBF was 82.42%, and the average selectivity of OPP was 48.39%. The main by-products are still dicyclohexyl, cyclohexylbenzene, biphenyl and 1,2,3,4-tetrahydrodibenzofuran, but the content of by-products is lower than that in Example 1. In addition to by-products, a small amount of 2-cyclohexylpheno...

Embodiment 3

[0051] Also use θ-Al 2 o 3 As a catalyst carrier, the preparation process is consistent with Example 2.

[0052] The active component of the catalyst is metal Pd, and the same volume impregnation method is used to support metal Pd equivalent to 2% equivalent of the carrier mass. The impregnation process is the same as in Example 2 except that palladium chloride is dissolved in concentrated hydrochloric acid and the specific content is different.

[0053] Catalyst finalization adopts roasting method, is consistent with embodiment 1, makes 2%Pd / θ-Al 2 o 3 catalyst composition.

[0054] Evaluation experiment:

[0055] The evaluation experiment adopts the same evaluation method as that of Example 1, except that the reduction condition is 300° C. and 80 ml / min of hydrogen flow for 3 hours, and other conditions are the same as that of Example 1.

[0056] Using the same evaluation method as in Example 1, the results obtained showed that the average conversion rate of DBF was 71....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Saturated water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com