9, 10- dihydro-9- oxa -10- phosphine hetero- phenanthrene -10- oxide compound and its derivant and method of preparing the same

A technology of phosphophenanthrene and oxide, which is applied in the field of preparation of new flame retardants, can solve the problems of CDOP synthesis time, complex production process, and long hydrolysis time, etc., and achieve the effect of simple method, simple product processing and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

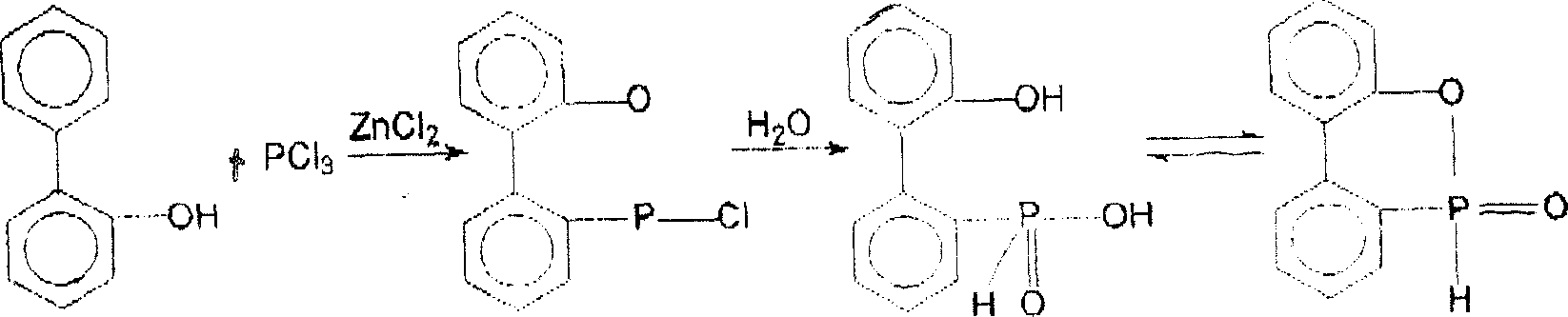

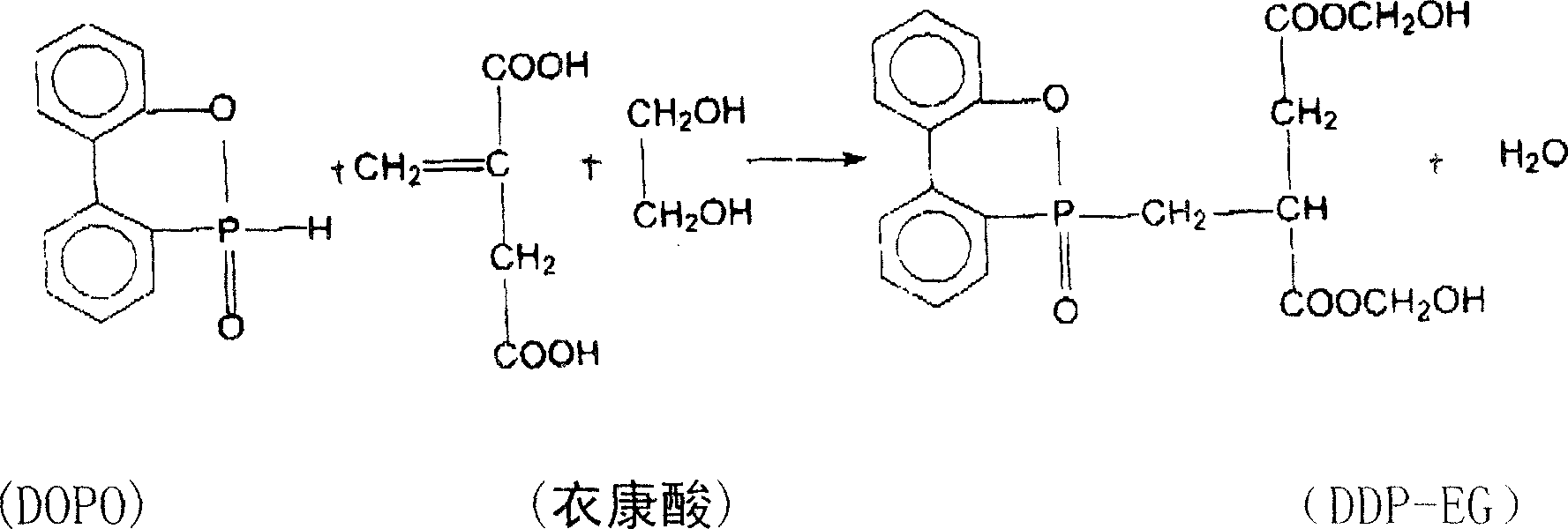

Method used

Image

Examples

Embodiment 1

[0055] Add 204Kg OPP, 2Kg ZnCl into the 1500L enamel reaction kettle 2 Heating, when the temperature rises to 50°C, it will start to melt, and when it reaches 80°C, the OPP will completely melt, start stirring, continue to heat up to 180°C, and start adding PCl dropwise 3 197Kg, at this time, HCl is released, 4h is added, and the reaction is continued for 1h. At this time, no HCl is released, stop heating, cool down to about 140°C, add an equal volume of mixed xylenes, and obtain a CDOP xylene mixed solution. Vacuumize (about 0.04mPa) to remove residual PCl 3 , then filtered to remove a small amount of residue. The filtrate is reheated to remove xylene first, and then distilled under a vacuum of 0.05-0.07mpa and 160-165°C to obtain water-like CDOP.

[0056] Then add about 200-300L of xylene into the enamel reaction kettle to dissolve CDOP, add the same amount of water, at this time, HCl is released, and when the temperature is 100°C and no HCl is released, stop the reaction...

Embodiment 2

[0058] According to Example 1, add 204KgOPP and 2Kg ZnCl2 to a 1500L enamel reaction kettle and heat it. When the temperature reaches 50°C, the OPP will start to melt. When the temperature reaches 80°C, the OPP will all melt. Add 197Kg PCl3, at this time, HCl is released, after adding 4h, continue to react for 2h, at this time, no HCl is released, when the temperature is lowered to 140°C, vacuumize, the vacuum degree is 0.04-0.05mpa, to remove residual PCl3, and then add the same amount Mix the xylenes to make a CDOP xylene solution. Cool to room temperature, filter to remove a small amount of solid residue. Then the xylene is evaporated from the solution at 0.04-0.05mpa, the temperature is raised to 160-165°C, 0.17KPa, and the CDOP is evaporated.

[0059] Dissolve CDOP in xylene again, add the same amount of water, at this time, at 80°C, HCl will be released, and at 100°C, no HCl will be released, and then continue to hydrolyze for 2 hours, and the liquid phase temperature i...

Embodiment 3

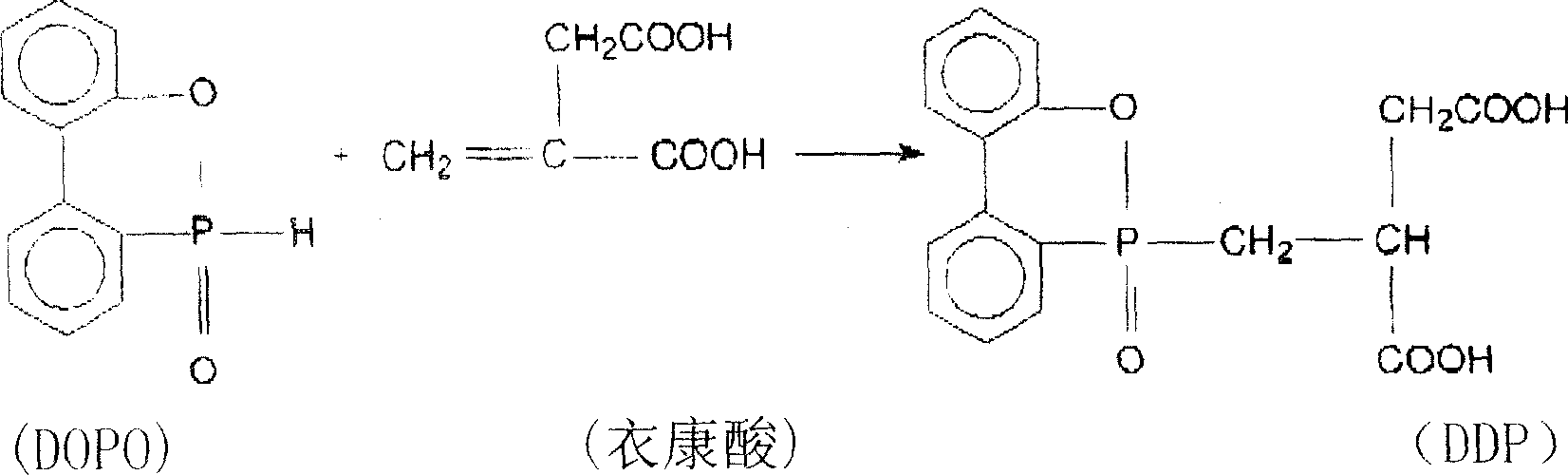

[0061] In the 1000L enamel reaction kettle, add DOPO411.3Kg, pass N 2 Heating up, at 150°C, add 247.5Kg of itaconic acid, and react for 4 hours to obtain a colorless and transparent resinous product of DOPO-itaconic acid (DDP), add acetone to crystallize, and obtain the white DDP of the DOPO derivative of the present invention. Powder 650.2Kg. Main technical indicators of the product: Yield 99% mp: 187-188°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com