Hybrid modified salt of phosphorus-containing acid, preparation method and application thereof

A technology of modification and phosphoric acid, which is applied in the field of preparation and hybrid modification of phosphoric acid-containing salts, can solve the problems of fire hazard expansion, poor compatibility, difficult industrial application, etc., and achieve the effect of improving decomposition temperature and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of hybrid modified phosphoric acid salt, its preparation steps are as follows:

[0056] (1) Preparation of amino-rich graphitic carbon nitride nanosheets:

[0057] 1) First heat the melamine to 330°C at a heating rate of 13.5°C / min and keep it warm for 10h;

[0058] 2) Then raise the temperature to 480°C at a heating rate of 12°C / min and keep it warm for 11 hours;

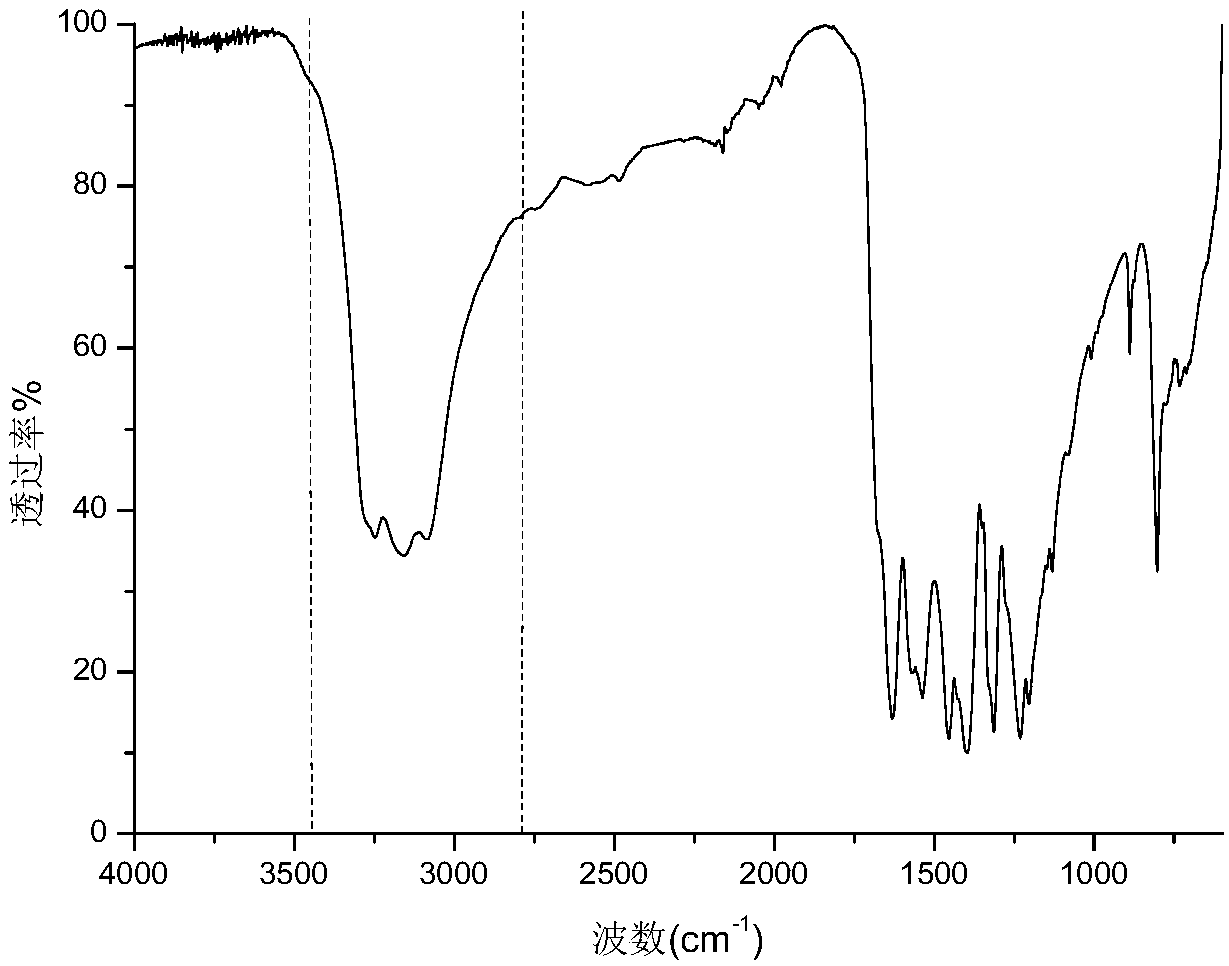

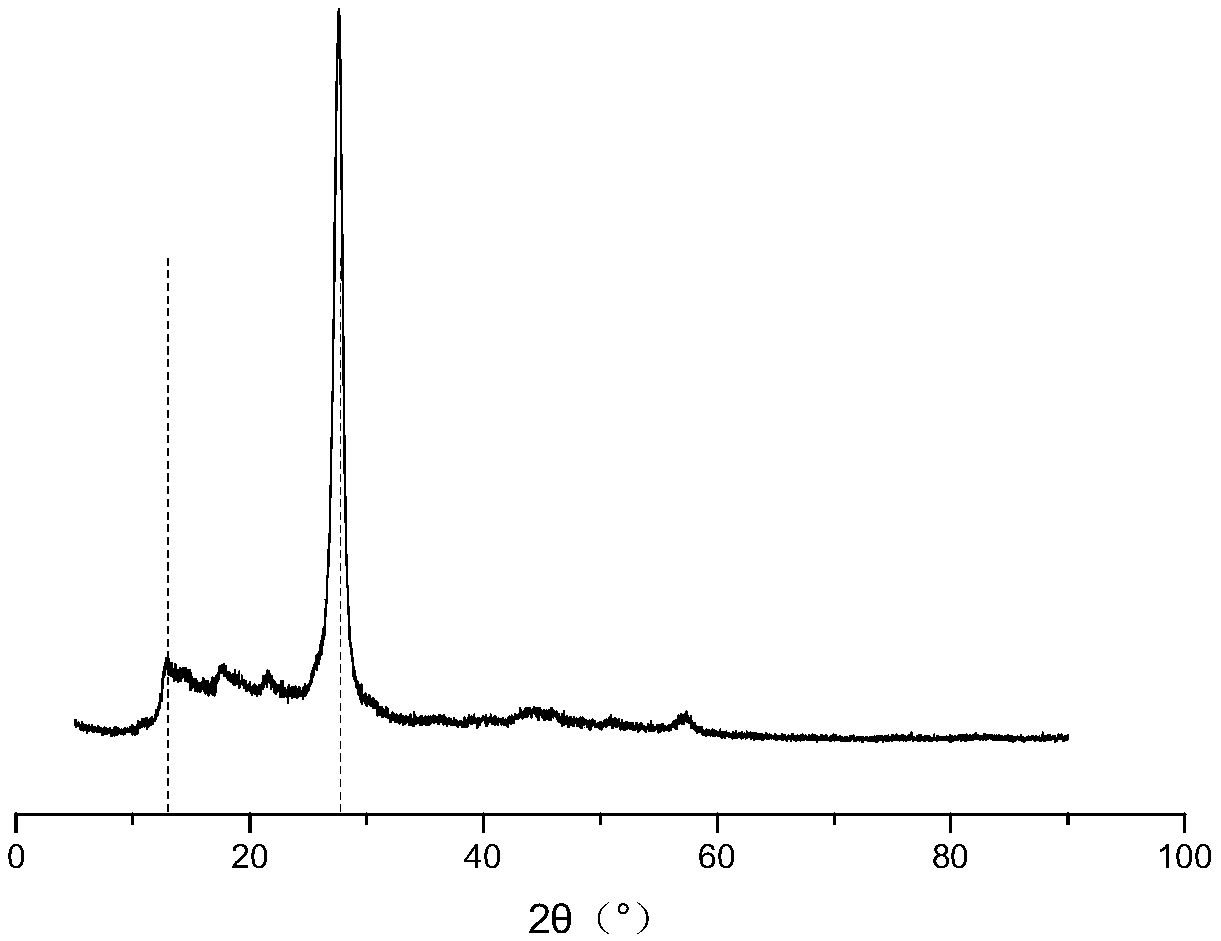

[0059] 3) Then raise the temperature to 500° C. at a heating rate of 0.5° C. / min and keep it warm for 3 hours to obtain amino-rich graphite carbon nitride; the nitrogen element content of the prepared amino-rich graphite carbon nitride is 66.5 wt%. Its chemical structure is rich in amino groups, such as figure 1 The shown Fourier transform infrared spectrum is at 2700-3400cm -1 It can be proved by the broad absorption peak at the position that the prepared amino-rich graphitic carbon nitride contains a graphite-like structure, which can also be proved by the sharp peaks near 13.5° and 27.5° in the ...

Embodiment 2

[0067] A kind of hybrid modified phosphoric acid salt, its preparation steps are as follows:

[0068] (1) Preparation of amino-rich graphitic carbon nitride nanosheets:

[0069] 1) First heat dicyandiamine to 350°C at a heating rate of 22°C / min and keep it warm for 5 hours;

[0070] 2) Then raise the temperature to 490°C at a heating rate of 19°C / min and keep it warm for 8 hours;

[0071] 3) Then raise the temperature to 530° C. at a heating rate of 11.5° C. / min and keep it warm for 9 hours to obtain amino-rich graphite carbon nitride; the nitrogen element content of the prepared amino-rich graphite carbon nitride is 67.3 wt%. Its chemical structure is rich in amino groups, and the prepared amino-rich graphite carbon nitride contains graphite-like structures.

[0072] 4) Completely immerse the amino-rich graphite carbon nitride in liquid oxygen and maintain the temperature T1 and maintain the pressure P1 for 22 minutes;

[0073] 5) Take out the amino-rich graphite carbon ni...

Embodiment 3

[0079] A kind of hybrid modified phosphoric acid salt, its preparation steps are as follows:

[0080] (1) Preparation of amino-rich graphitic carbon nitride nanosheets:

[0081] 1) First heat cyanamide to 300°C at a heating rate of 5°C / min and keep it warm for 6 hours;

[0082] 2) Then raise the temperature to 400°C at a heating rate of 3.5°C / min and keep it warm for 10 hours;

[0083] 3) Then raise the temperature to 550° C. at a heating rate of 18° C. / min and keep it warm for 2 hours to obtain amino-rich graphitic carbon nitride; the nitrogen content of the prepared amino-rich graphitic carbon nitride is 66 wt%. The chemical structure is rich in amino groups, and the prepared amino-rich graphitic carbon nitride contains a graphite-like structure.

[0084] 4) Completely immerse the amino-rich graphite carbon nitride in liquid helium and maintain the temperature T1 and maintain the pressure P1 for 18 minutes;

[0085] 5) Take out the amino-rich graphite carbon nitride, plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com