Ammonium polyphosphate flame retardant and preparing method thereof

A technology of ammonium polyphosphate and flame retardant, which is applied in the field of flame retardants and can solve problems such as poor synergistic flame retardant effect, poor compatibility, and poor thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a kind of preparation method of ammonium polyphosphate flame retardant, it is characterized in that, comprises the following steps:

[0042] A) After the carbon nitride and the solvent are ultrasonically stirred, a dispersion is obtained;

[0043]B) After mixing and reacting the dispersion liquid obtained in the above step A) with ammonium polyphosphate, an ammonium polyphosphate flame retardant is obtained.

[0044] In the present invention, carbon nitride, solvent and ammonium polyphosphate are used as raw materials, carbon nitride and solvent are assisted by ultrasound to obtain dispersion liquid, and carbon nitride is used as the surface coating layer, and ammonium polyphosphate is used as the inner core. Ammonium polyphosphate flame retardant, which is a kind of halogen-free flame retardant.

[0045] In the present invention, the carbon nitride and the solvent are ultrasonically stirred to obtain a dispersion liquid; the mass ra...

Embodiment 1

[0052] Add 5.3 g of carbon nitride into a 1000 ml three-necked flask, then add 400 g of isopropanol into the three-necked flask, and perform ultrasonic stirring for 4 hours to obtain a dispersion.

[0053] Then add 100 grams of ammonium polyphosphate to the above dispersion, raise the temperature to 100°C, stir and react for 10 hours at the same time, then cool the dispersion to room temperature, suction filter and dry, and dry the filter cake at 80°C for 7 hours to obtain Ammonium polyphosphate flame retardant CNAPP5.

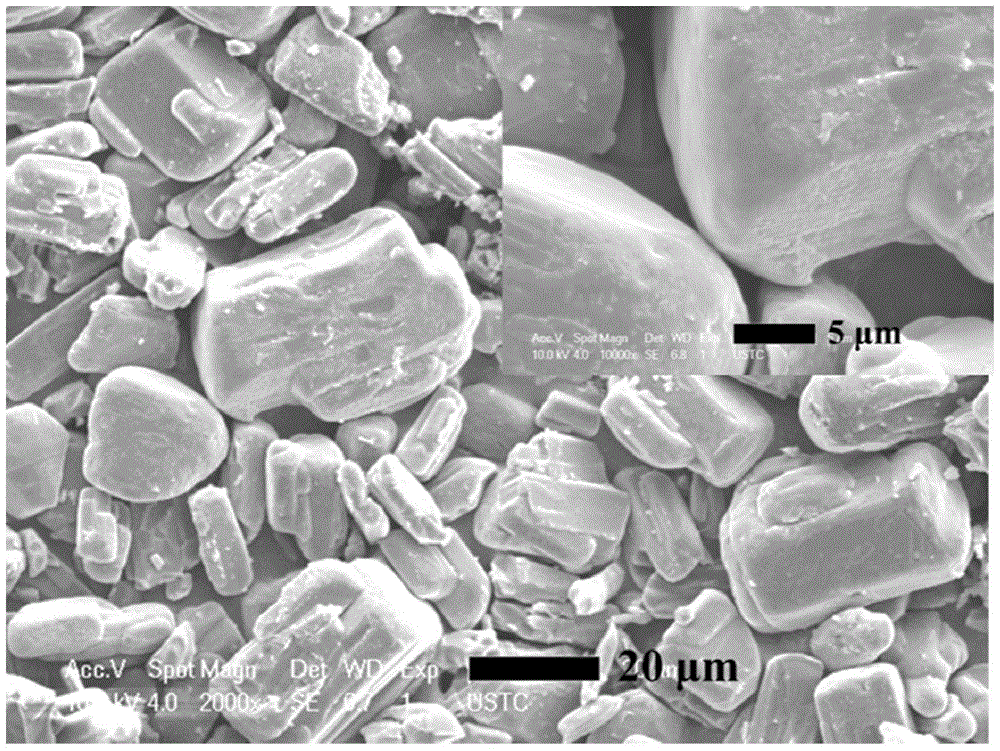

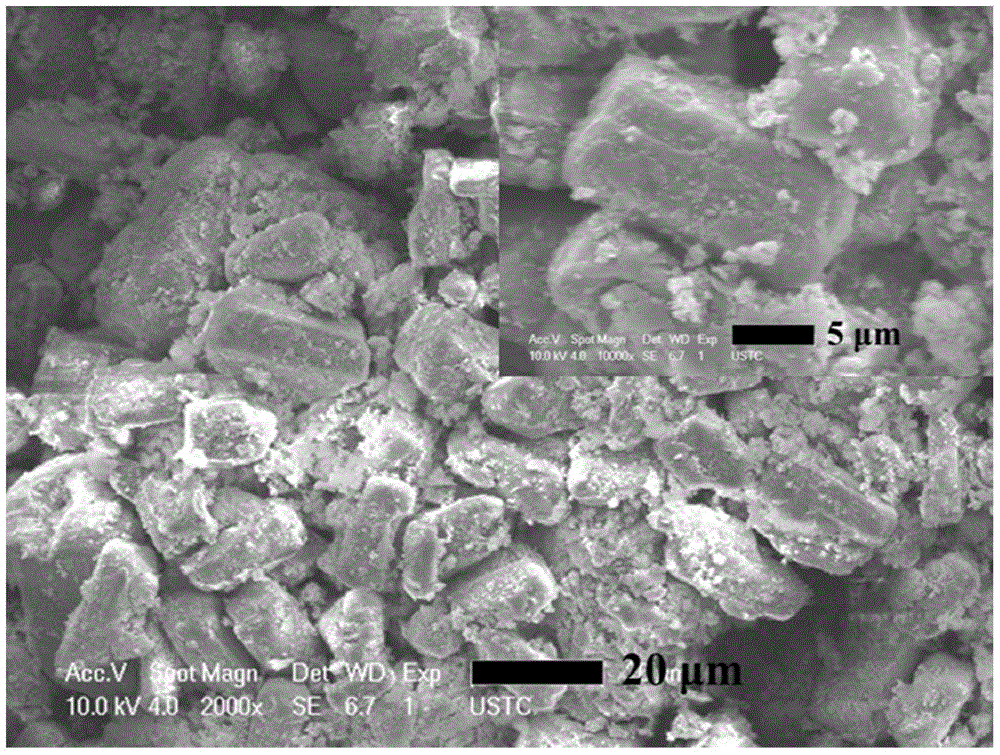

[0054] The ammonium polyphosphate flame retardant CNAPP5 prepared by the above steps is scanned by scanning electron microscope, see figure 2 , figure 2 It is the SEM scanning electron microscope picture of the ammonium polyphosphate flame retardant prepared in Example 1. see figure 1 , figure 1 It is the SEM scanning electron microscope picture of uncoated ammonium polyphosphate. Depend on figure 1 with figure 2 It can be seen from the comparison th...

Embodiment 2

[0057] 11.1 g of carbon nitride was added into a 2000 ml three-necked flask, and 900 g of isopropanol was added into the three-necked flask, and ultrasonically stirred for 4.5 hours to obtain a dispersion.

[0058] Then add 100 grams of ammonium polyphosphate to the above dispersion, raise the temperature to 100°C, stir and react for 16 hours at the same time, then cool the dispersion to room temperature, suction filter and dry, and dry the filter cake at 70°C for 8 hours to obtain Ammonium polyphosphate flame retardant CNAPP10.

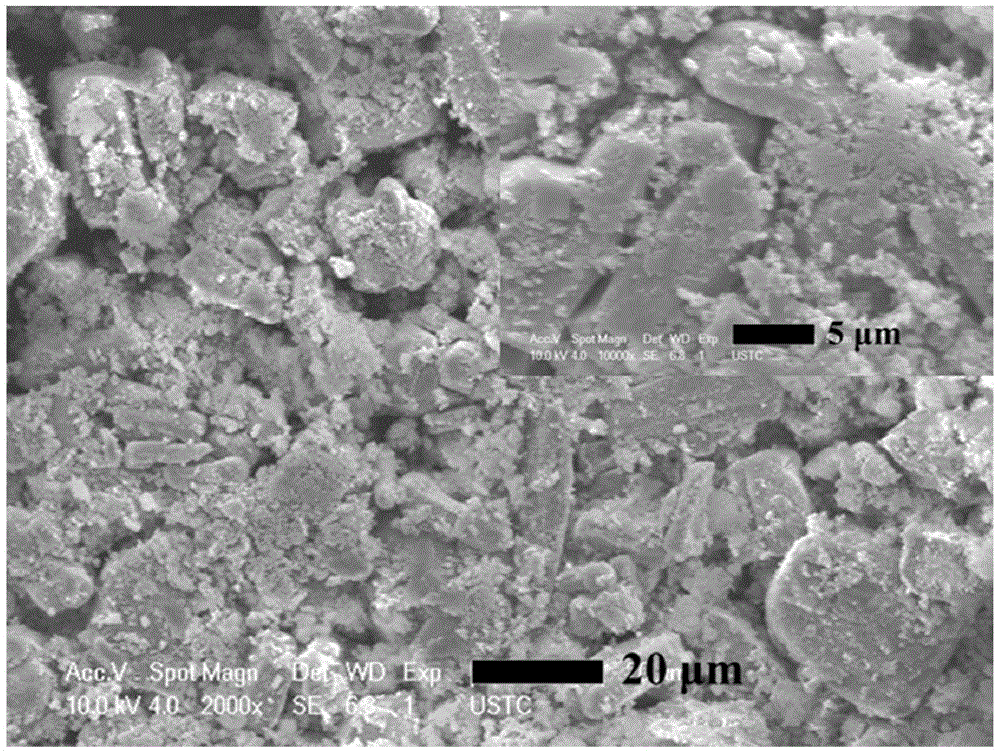

[0059] The ammonium polyphosphate flame retardant CNAPP10 prepared by the above steps is scanned by scanning electron microscope, see image 3 , image 3 SEM electron microscope scanning picture of the ammonium polyphosphate flame retardant prepared for Example 2. Depend on image 3 It can be seen that the carbon nitride-coated ammonium polyphosphate flame retardant prepared in Example 2 of the present invention has a rough surface and is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com