Polystyrene fire-retardant foam material and prepapration method thereof

A technology for flame retardant foam and polystyrene, which is applied in the field of polystyrene flame retardant foam material and its preparation, can solve the problems of complex preparation method, unsatisfactory flame retardant performance of products, and many components involved in flame retardant polystyrene foam. , to achieve the effect of simple and easy preparation method, low cost and good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of polystyrene flame-retardant foam material, comprising the following steps:

[0042] (a), pre-expanding and curing the expandable polystyrene particles;

[0043] (b) Mix the liquid thermoplastic phenolic resin with the mature expandable polystyrene particles, and vacuumize at 50-70°C for 25-35min;

[0044] (c) Add expanded graphite and mix evenly, vacuumize at 50-70° C. for 1-2 hours, and then foam molding to obtain the final product.

[0045] In the preparation method of the polystyrene flame-retardant foam material provided by the embodiment of the present invention, the expandable polystyrene particles are pre-foamed and matured, mixed evenly with the thermoplastic phenolic resin dissolved in the organic solvent, and part of the organic solvent is removed to increase the Viscosity, then adding expanded graphite, then vacuum drying to completely remove the organic solvent, and finally foaming to prepare polys...

Embodiment 1

[0049] In percent by weight, get the following materials, expandable polystyrene particles 65%, thermoplastic phenolic resin 20%, expanded graphite 15%, wherein, thermoplastic phenolic resin is dissolved with ethanol, and the addition of ethanol is 8% of thermoplastic phenolic resin weight %;

[0050] Pre-expand the expandable polystyrene particles, the pre-expansion temperature is 120°C, the pre-expansion time is 5min, and then aged at room temperature for 24h;

[0051] Mix the liquid thermoplastic phenolic resin with the cured expandable polystyrene particles, and vacuumize at 60°C for 30 minutes;

[0052] Add expanded graphite and mix well, vacuumize at 60°C for 2h, and then foam molding to obtain the final product.

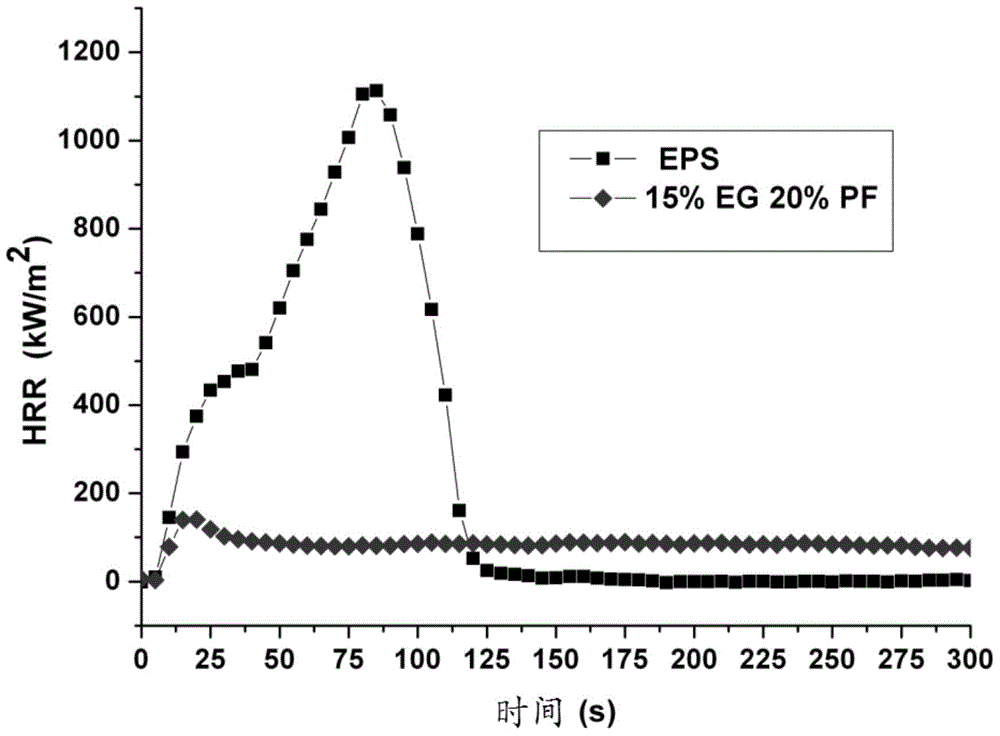

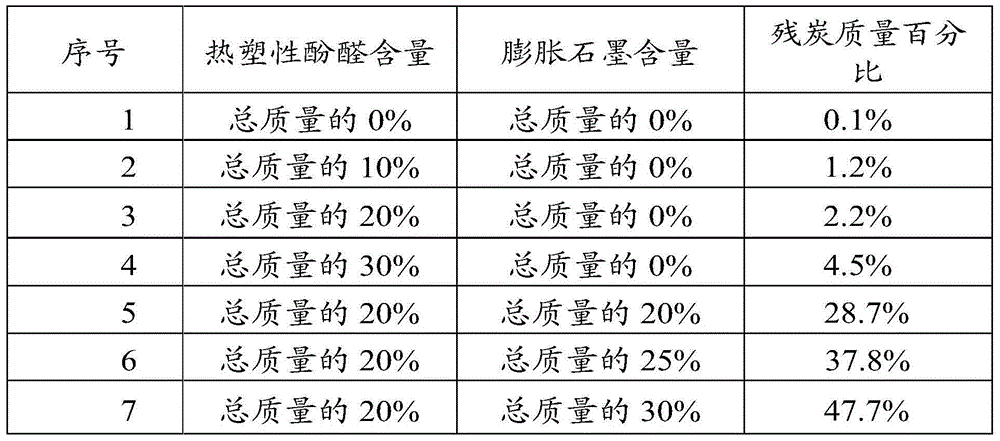

[0053] The measured limit oxygen index value of the final product is 30.5%, and the amount of carbon residue at 400-600 °C measured by thermogravimetric loss is 37.8% of the total mass; and the heat release rate is determined for the final product polystyrene...

Embodiment 2

[0055] In percent by weight, get the following materials, expandable polystyrene particles 85%, thermoplastic phenolic resin 5%, expanded graphite 10%, wherein, thermoplastic phenolic resin is dissolved with acetone and chloroform, and the addition amount of acetone and chloroform is thermoplastic phenolic resin 7% of resin weight;

[0056] Pre-expand the expandable polystyrene particles, the pre-expansion temperature is 105°C, the pre-expansion time is 15min, and then aged at room temperature for 10h;

[0057] Mix the liquid thermoplastic phenolic resin with the cured expandable polystyrene particles, and vacuumize at 60°C for 30 minutes;

[0058] Add expanded graphite and mix well, vacuumize at 60°C for 1.5h, and then foam molding to obtain the final product.

[0059] The measured limiting oxygen index value of the final product is 25.3%, and the amount of carbon residue at 400-600 °C measured by thermogravimetric loss is 20.8% of the total mass; and the heat release rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com