P-N-Si flame-retardant nanogel and preparation method and application thereof

A nanogel, p-n-si technology, applied in the manufacture of fire-resistant and flame-retardant filaments, artificial filaments made of viscose, etc., can solve the problems of unfriendly environment, releasing a large amount of poisonous gas and smoke, environmental hazards, etc. Achieve the effects of rich benzene rings and carbon chains, improved flame retardancy, and high carbon residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

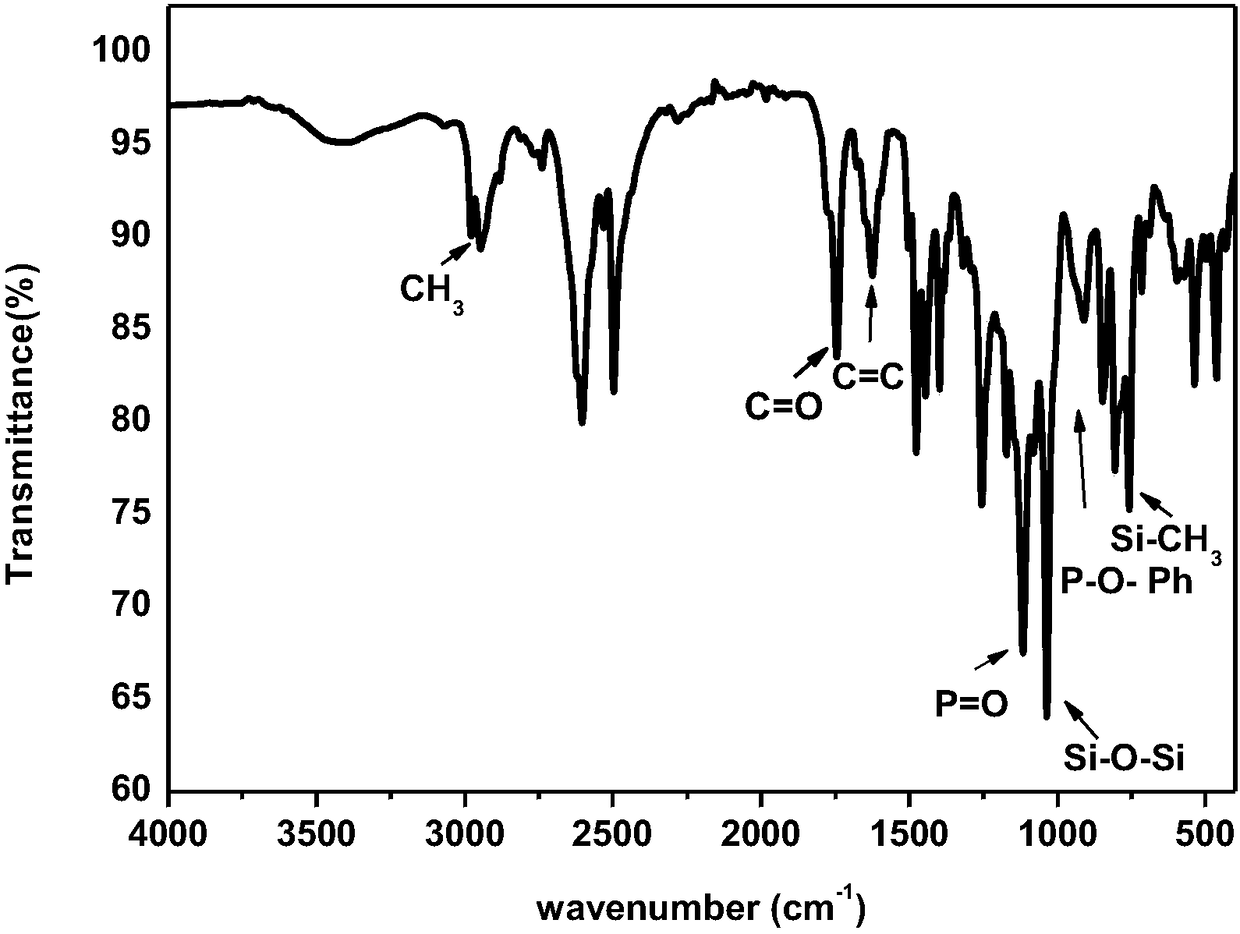

Method used

Image

Examples

Embodiment 1

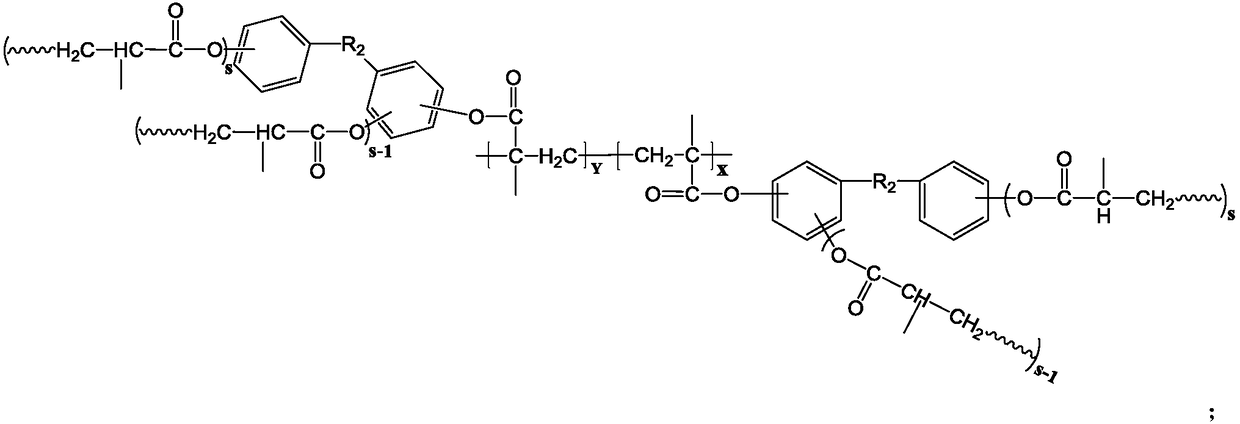

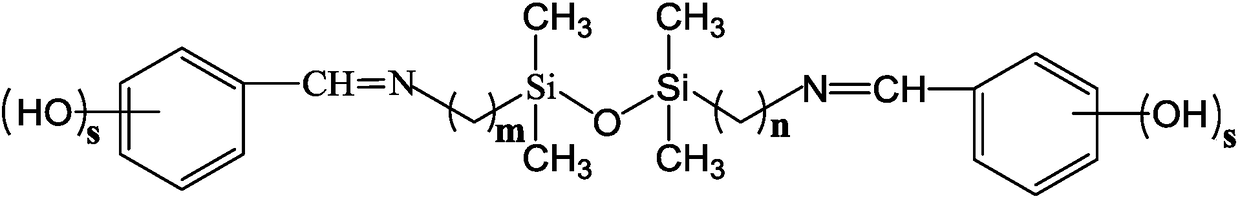

[0045] (1) Weigh 2.76g of 0.02mol 3,4-dihydroxybenzaldehyde and dissolve it in 30ml of methanol, put 1mg of zinc acetate as a catalyst, weigh 0.01mol of 1,3-bis(3-aminopropyl)-1, 2.48g of 1,3,3-tetramethyldisiloxane, dissolved in 15ml of methanol, put into a 100ml constant pressure separatory funnel, and slowly added dropwise to the solution containing 3,4-dihydroxybenzene within 1 hour In a three-necked flask of formaldehyde, magnetically stirred, heated to 70°C in a water bath, and reacted for 10 hours, the reactant was precipitated with a mixture of ice and water, and vacuum-dried at 50°C for 12 hours, and the obtained intermediate product (I) was brown-black powder.

[0046] (2) Weigh 0.01mol intermediate product (I) 4.88g and 0.02mol 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide 4.32g, with 60ml absolute ethanol as solvent, The oil bath was heated to 70°C and reacted for 12 hours. The reacted product was precipitated with a mixture of ice and water, and dried in vacu...

Embodiment 2

[0056] (1) Dissolve 0.02mol 2.44g p-hydroxybenzaldehyde in 30ml methanol, put 1mg zinc acetate as catalyst, weigh 0.01mol 1,3-bis(3-aminoethyl)tetramethyldisiloxane 2.20g, dissolved in 15ml of methanol, put into a 100ml constant pressure separatory funnel, slowly added dropwise to the three-necked flask containing p-hydroxybenzaldehyde within 1 hour, stirred magnetically, heated the water bath to 70°C, and reacted After 10 hours, the reactant was precipitated with a mixture of ice and water, and dried under vacuum at 50° C. for 12 hours, and the obtained intermediate product (I) was brownish yellow powder.

[0057] (2) Weigh 0.01mol intermediate product (I) 4.28g and 0.02mol 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide 4.32g, with 50ml absolute ethanol as solvent, The oil bath was heated to 70°C and reacted for 12 hours. The reacted product was precipitated with a mixture of ice and water, and dried in vacuum at 60°C for 12 hours. The obtained intermediate product (II) w...

Embodiment 3

[0068] (1) Weigh 0.02mol 2.44g o-hydroxybenzaldehyde and dissolve it in 30ml methanol, put 1mg zinc acetate as catalyst, weigh 0.01mol 1,3-bis(3-aminopropyl)tetramethyldisiloxane 2.48g, the reaction conditions are the same as in Example 1, and the intermediate product (I) obtained is a bright yellow powder.

[0069] (2) Weigh 4.56 g of 0.01 mol of intermediate product (I) and 2.76 g of 0.02 mol of diethyl phosphate, the reaction conditions are the same as in Example 1, and the obtained intermediate product (II) is gray powder.

[0070] (3) Weigh 0.0005mol intermediate product (II) 0.382g and 0.005mol methacryloyl chloride 0.52g (0.48ml), dissolve in 15ml tetrahydrofuran, 0.005mol triethylamine 0.5g (0.7ml) is a binding agent, react The conditions were the same as in Example 1, and the obtained intermediate product (III) was a white powder.

[0071] (4) With 20ml dimethyl sulfoxide as a solvent and 0.01g ammonium persulfate as an initiator, 0.5g of the intermediate product (II...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com