Nitrogen-rich group functionalized graphene oxide and preparation method and application thereof

A functionalized graphene technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as processing difficulties, dispersion stability effects, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

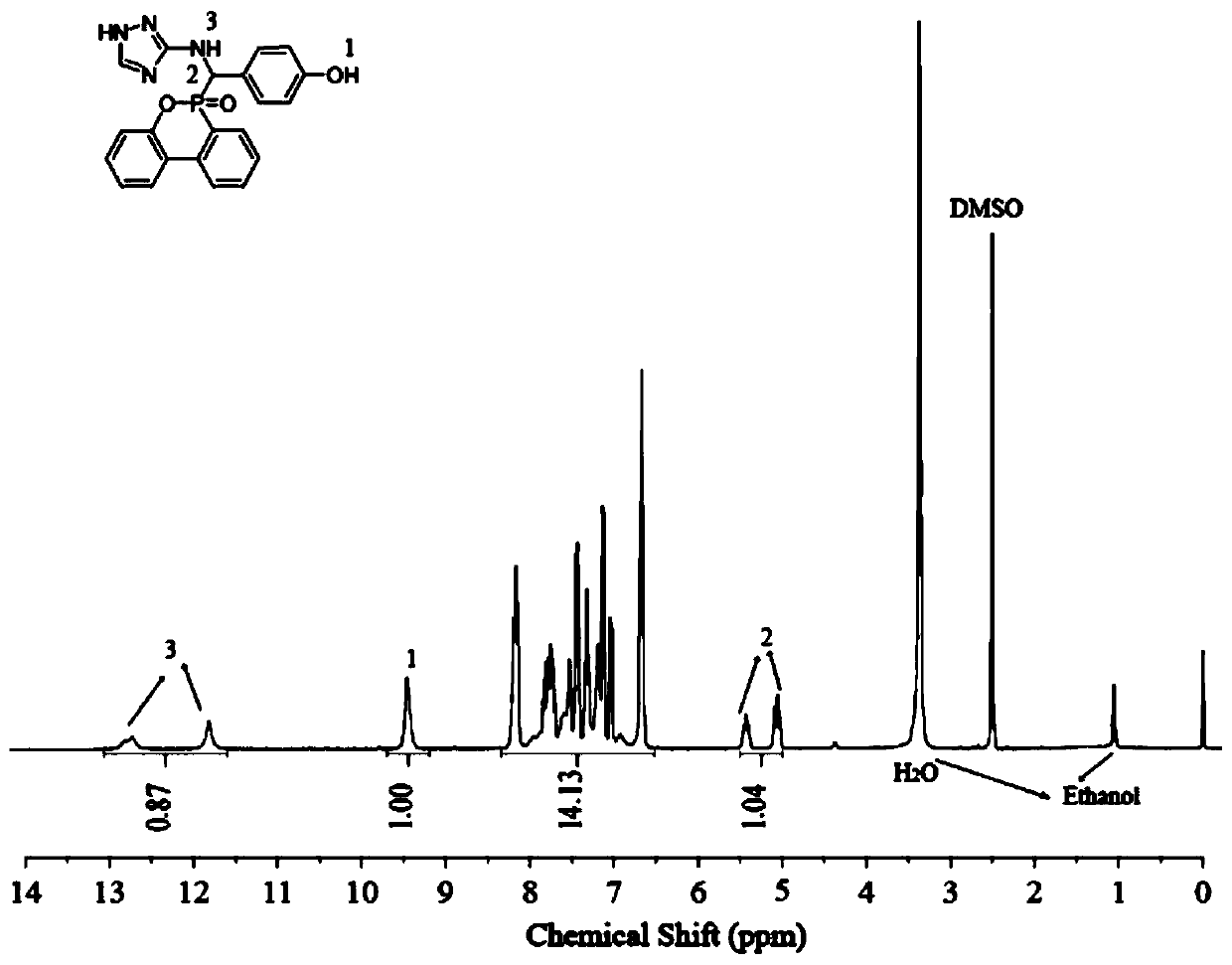

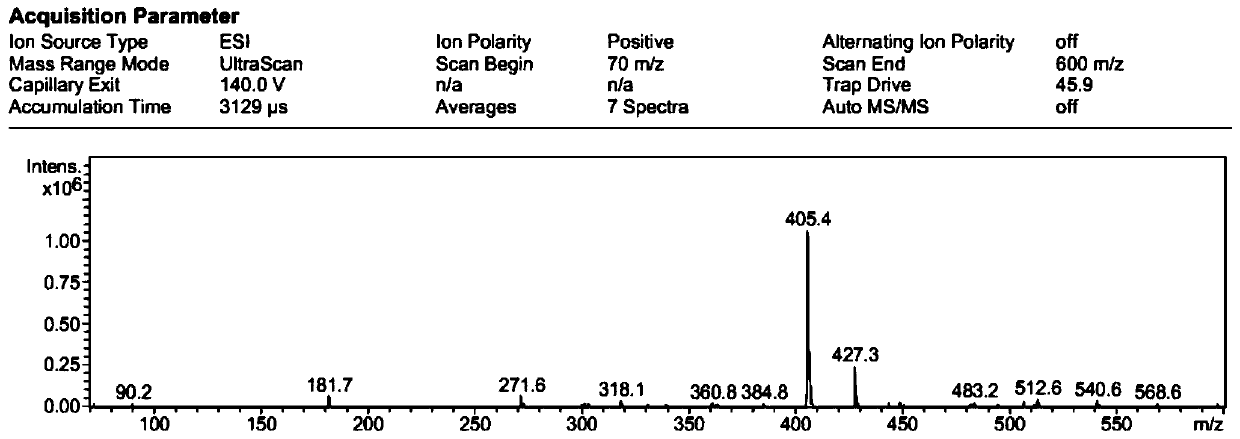

[0025] (1) Synthesis of compounds containing phosphorus and nitrogen elements

[0026] In a 150mL three-necked flask, add 1.83g of 3-amino-1,2,4-triazole and 2.66g of p-hydroxybenzaldehyde dissolved in 30mL of absolute ethanol, and stir the reaction at a reaction temperature of 50°C under nitrogen protection. Hour. Then, 30 mL of absolute ethanol containing 4.70 g DOPO was added dropwise with a constant pressure dropping funnel, and the reaction was continued for 12 hours. Finally, it was cooled to room temperature, and the product was purified by vacuum filtration and drying.

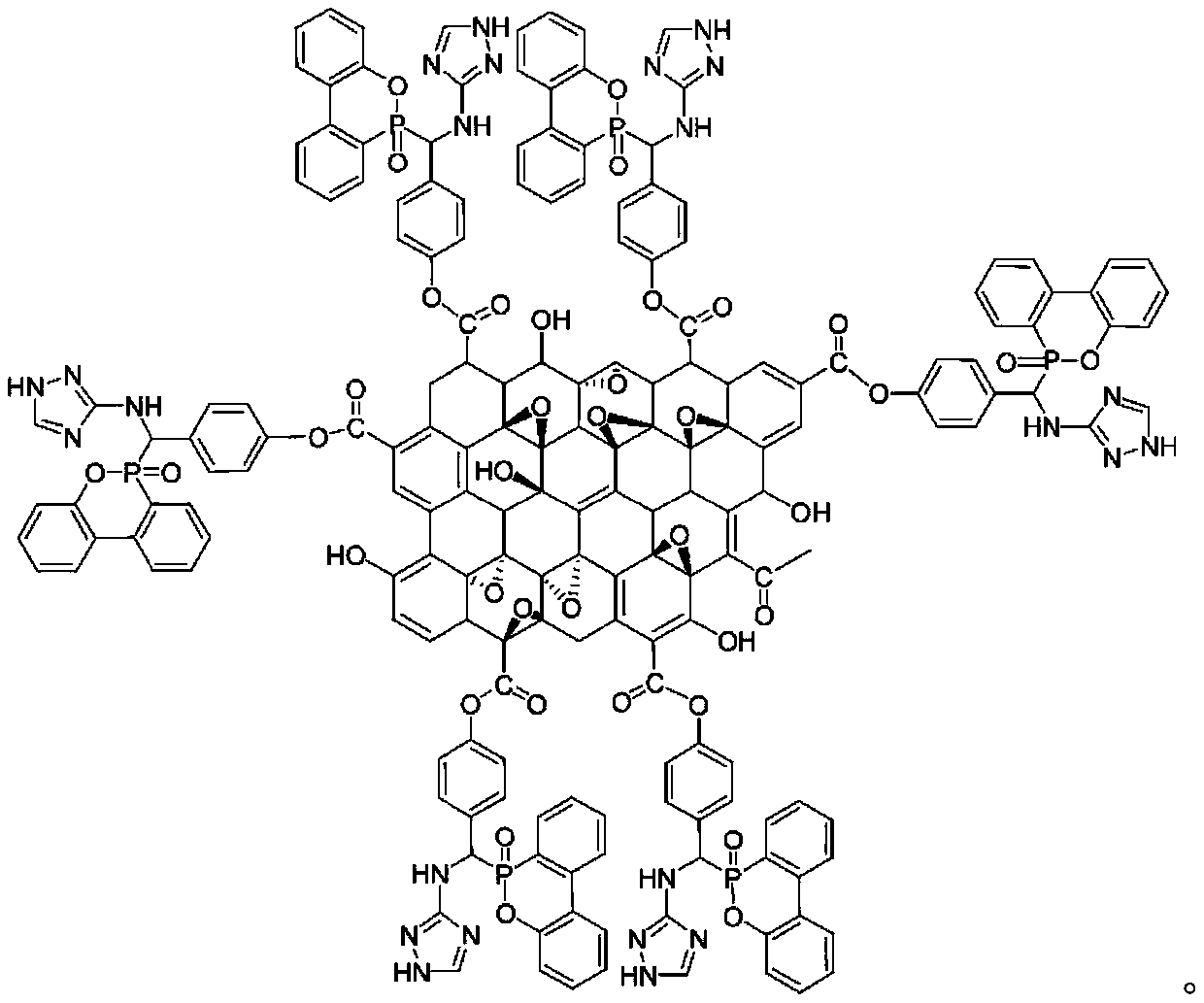

[0027] (2) Synthesis of Phosphorus and Nitrogen Functionalized Graphene

[0028] After 50 mg of graphene oxide was sonicated in DMF for 1 hour, 15 mL of DMF dissolved in 25 mg of DMAP, 100 mg of DCC and 0.174 g of a compound containing phosphorus and nitrogen was added, and stirred at room temperature for 36 hours. After the reaction, the product was washed with DMF and deionized water several times...

Embodiment 2

[0031] (1) Synthesis of compounds containing phosphorus and nitrogen elements

[0032] In a 150mL three-necked flask, add 1.83g of 3-amino-1,2,4-triazole and 2.66g of p-hydroxybenzaldehyde dissolved in 30mL of anhydrous methanol, and stir the reaction at a reaction temperature of 50°C under nitrogen protection. Hour. Then, 30 mL of anhydrous methanol containing 4.70 g DOPO was added dropwise with a constant pressure dropping funnel, and the reaction was continued for 12 hours. Finally, it was cooled to room temperature, and the product was purified by vacuum filtration and drying.

[0033] (2) Synthesis of Phosphorus and Nitrogen Functionalized Graphene

[0034] After 50 mg of graphene oxide was sonicated in DMF for 1 hour, 15 mL of absolute ethanol dissolved in 50 mg of DMAP, 200 mg of DCC and 0.18 g of phosphorus and nitrogen-containing compounds were added, and stirred at room temperature for 36 hours. After the reaction, the product was washed with absolute ethanol and ...

Embodiment 3

[0036] (1) Synthesis of compounds containing phosphorus and nitrogen elements

[0037] In a 150mL three-neck flask, add 1.83g of 3-amino-1,2,4-triazole and 3.16g of p-hydroxybenzaldehyde dissolved in 30mL of absolute ethanol, and stir the reaction at a reaction temperature of 50°C under nitrogen protection. Hour. Then, 30 mL of absolute ethanol containing 5.21 g DOPO was added dropwise with a constant pressure dropping funnel, and the reaction was continued for 12 hours. Finally, it was cooled to room temperature, and the product was purified by vacuum filtration and drying.

[0038] (2) Synthesis of Phosphorus and Nitrogen Functionalized Graphene

[0039] After 100 mg of graphene oxide was sonicated in DMF for 1 hour, 15 mL of DMF dissolved in 50 mg of DMAP, 150 mg of EDC and 0.20 g of a compound containing phosphorus and nitrogen was added, and stirred at room temperature for 36 hours. After the reaction, the product was washed with DMF and deionized water several times, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com