Preparation method for benzoxazine resin nano-polymer sphere and benzoxazine resin nano-polymer carbon sphere

A nanopolymer and benzoxazine technology, applied in the field of controllable preparation of spherical nanomaterials, can solve the problems of uneven product size, difficult separation and purification, complicated operation, etc., and achieve uniform particle size, simple and fast operation, and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.11g resorcinol and put it into a round bottom flask, add 50ml deionized water and stir at room temperature, add 0.05g surfactant F127 (produced by Fluka company) after dissolving, add 146μl 37% formaldehyde solution and 0.029 1,6-g of 1,6-hexamethylenediamine, continue to stir, after the white colloid is obtained, the above reaction solution is moved to a water bath at 80°C, and stirred for 24 hours to obtain an aqueous solution of monodisperse nano-polymer spheres, after 12000r / min After centrifugation for 10 min, wash with water and ethanol, and dry the product at room temperature or in an oven at 50°C overnight.

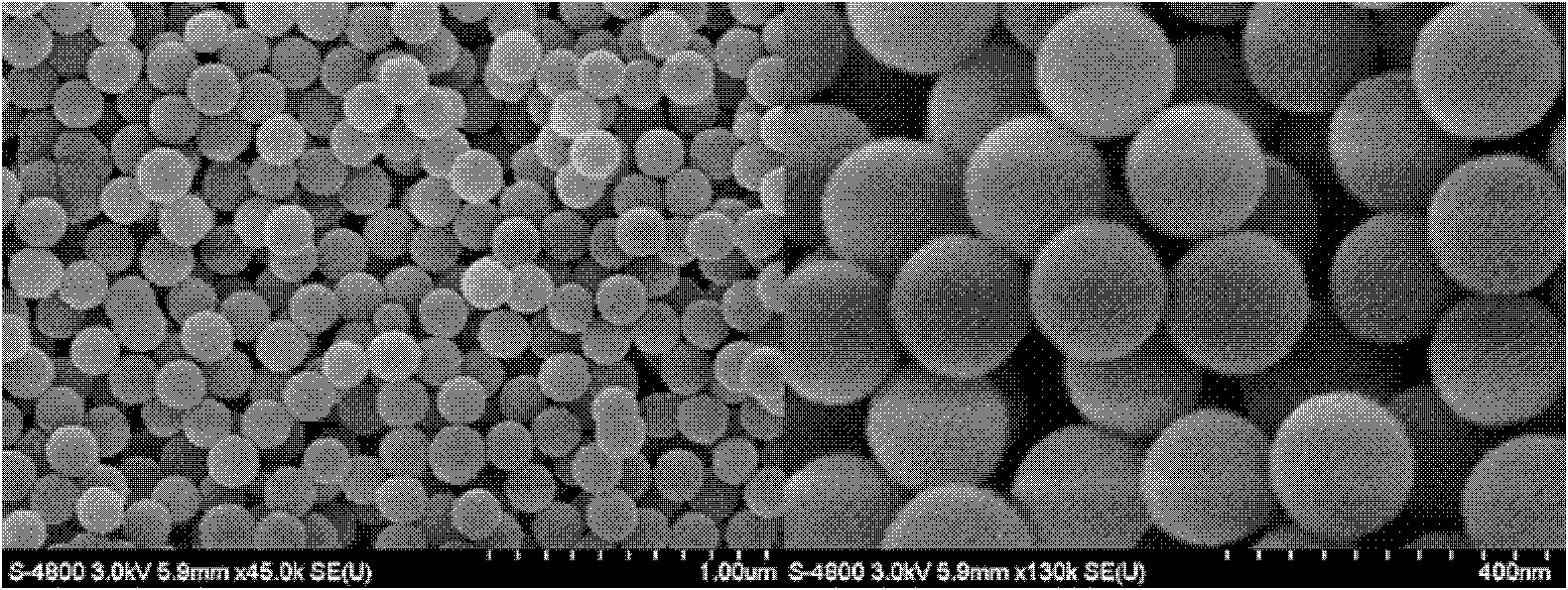

[0026] The obtained nanometer polymer sphere diameter of the present embodiment is 180 ± 10nm, and its scanning electron microscope is as follows: figure 1 shown.

Embodiment 2

[0028] Place the nanometer polymer balls prepared in Example 1 into a carbonization furnace for carbonization, and use an inert gas protection to rise from room temperature to 400°C at a rate of 1-3°C / min, and dry at a constant temperature for 60 minutes; The rate was increased from 400°C to the final carbonization temperature of 900°C, and the temperature was kept constant for 60 minutes to obtain carbonized nano-carbon spheres with shape retention.

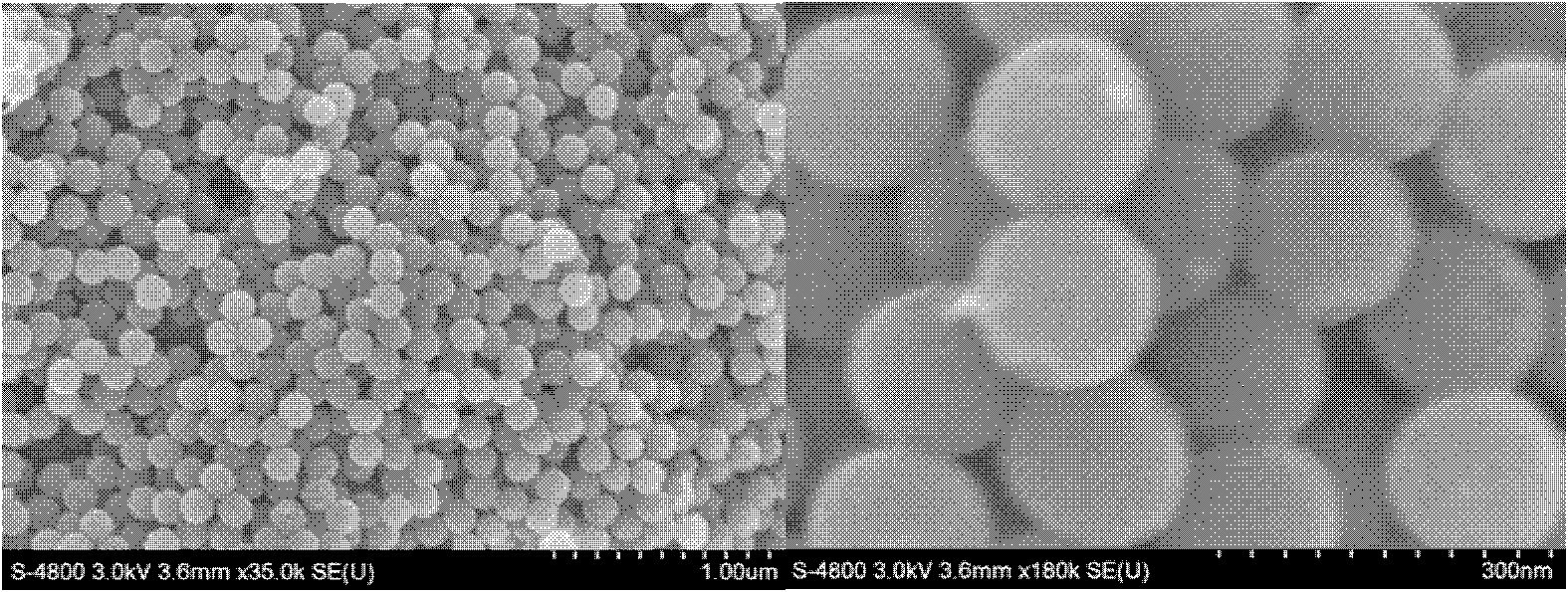

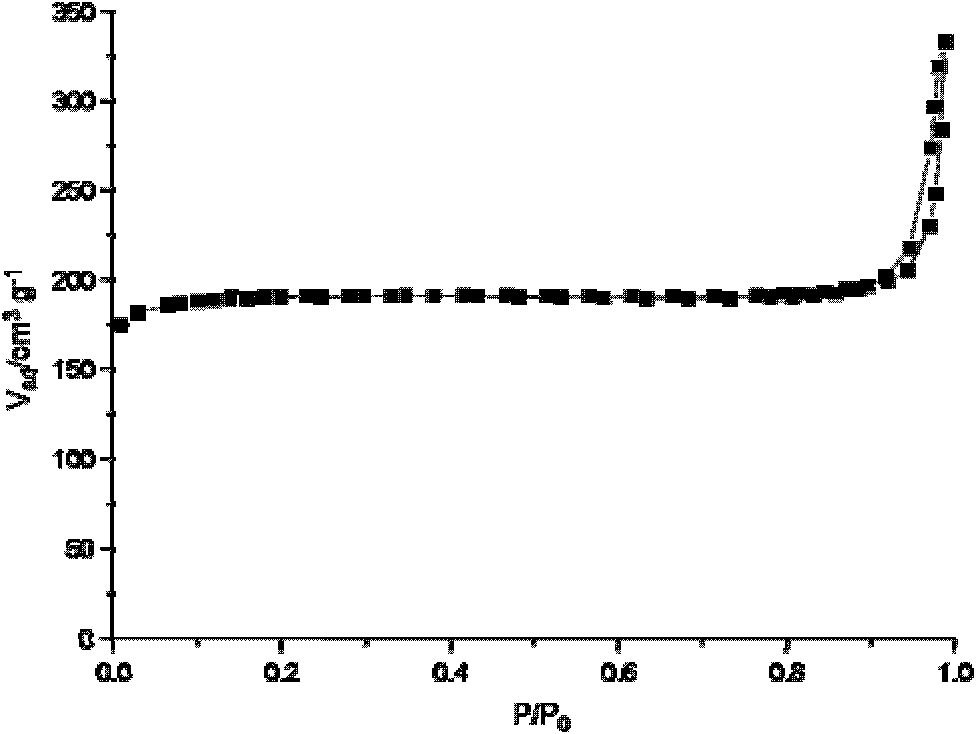

[0029] The particle size of nano carbon spheres obtained in this embodiment is 160 ± 5nm, and its scanning electron microscope is as follows: figure 2 As shown, its BET specific surface area is 635m 2 g -1 , micropore volume 0.27cm 3 g -1 .

Embodiment 3

[0031] Weigh 0.11g of resorcinol into a round bottom flask, add 50ml of deionized water and stir at room temperature, add 0.01g of surfactant F127 after dissolving, add 146μl of 37% formaldehyde solution and 33μl of ethylenediamine after stirring completely, Continue stirring to obtain a white colloid, move the above reaction solution to a water bath at 80°C, and stir for 24 hours to obtain an aqueous solution of monodisperse nano-polymer spheres, centrifuge at 12000r / min for 10min, wash with water and ethanol, and The product was dried overnight at room temperature or in an oven at 50 °C.

[0032] The diameter of the nano-polymer spheres prepared in this example is 700±50 nm.

[0033] The above-mentioned nano-polymer spheres are placed in a carbonization furnace for carbonization to obtain nano-polymer carbon spheres with a particle size of 550±20nm and a BET specific surface area of 610m 2 g -1 , micropore volume 0.26cm 3 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com