High-polymer bromine flame retardant/nano clay compound flame-retardant ABS (acrylonitrile-butadiene-styrene) resin and preparation method thereof

A technology of brominated flame retardant and ABS resin, which is applied in the field of flame retardant ABS resin compounded with polymer brominated flame retardant and nano-clay and its preparation, can solve the problem of corrosive, decabromodiphenyl Ether is easy to migrate, poor light stability and other problems, to achieve good mechanical properties and thermal stability, not easy to migrate, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

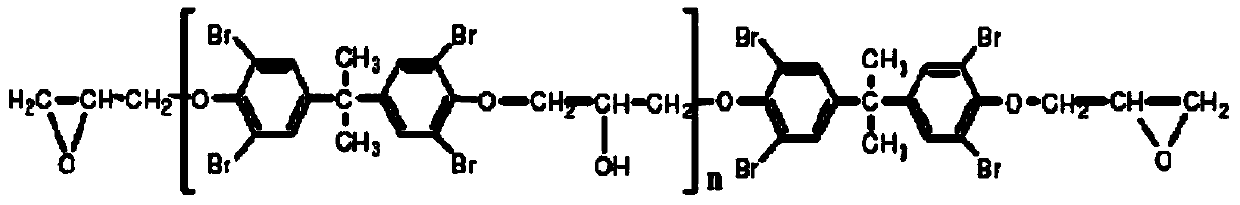

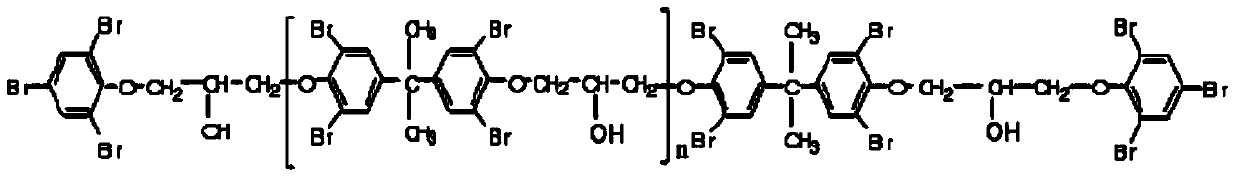

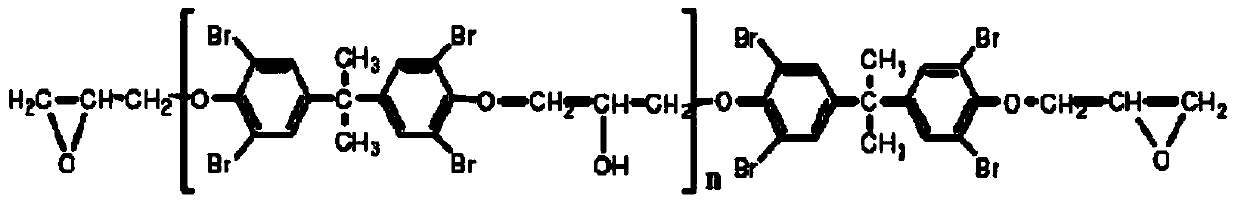

Image

Examples

Embodiment

[0036] Example thermal stability

[0037] Take 5-10 mg of powder sample, and use SDTQ600 thermogravimetric analyzer (TA, USA) to measure the thermal stability of the material in air atmosphere, the heating rate is 10 °C / min, and the temperature range is 50-700 °C. After taking the average value of three parallel experiments, the experimental data obtained are shown in Table 2.

[0038] Table 2 Thermal stability of material embodiments of the present invention

[0039]

[0040] a T onset Expressed as the temperature when the sample thermal weight loss is 5wt%; T max refers to the temperature at the maximum thermal weight loss rate,

[0041] max1, max2, and max3 correspond to the first, second, and third maximum thermal decomposition rates, respectively.

[0042] It can be found from Table 2 that the thermal degradation temperature of each embodiment far exceeds the molding processing temperature of ABS resin, and the residue mass at 500°C exceeds 20wt%, indicating that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com