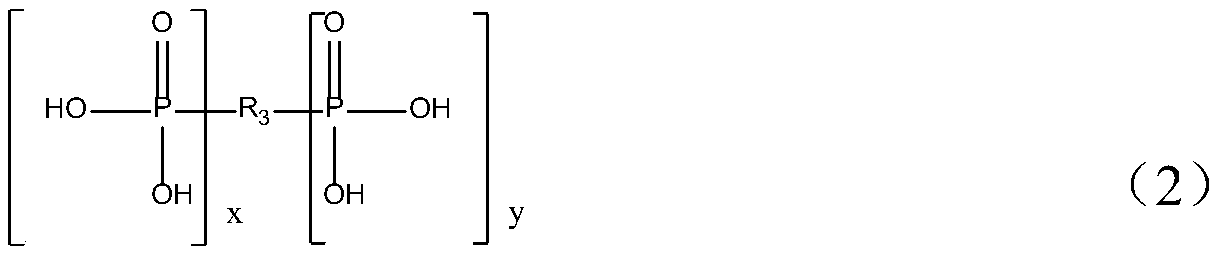

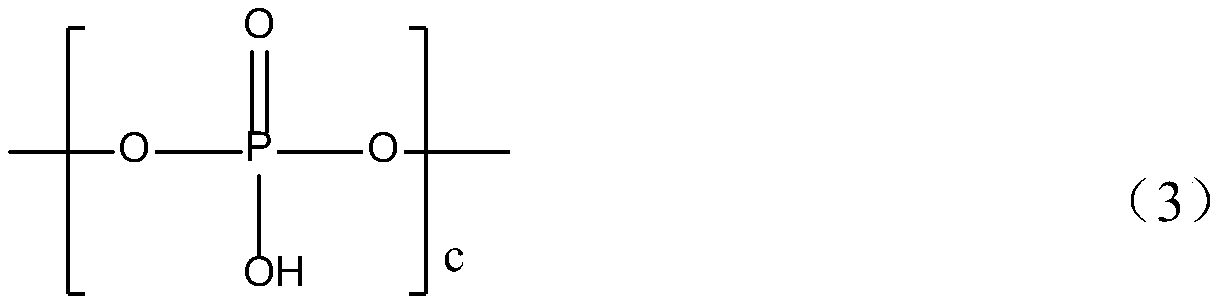

Novel organic phosphide flame retardant and preparation method and application thereof

A technology of organic phosphorus and flame retardants, applied in the field of flame retardants, can solve the problems of high processing temperature of polyphenylene ether, inability to achieve flame retardant effect, pure white color is not easy to match, etc., to improve the carbon residue rate and save production Expenses, high whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Dissolve 122g of diethyl hypophosphorous acid and 611g of sodium hexametaphosphate in 1000g of water at the same time to obtain solution ①, then add 40g of sodium hydroxide to solution ① to obtain the corresponding sodium salt mixture solution ②; dissolve 777g of aluminum sulfate octadecahydrate Obtain the solution ③ in 1000g of water; add the solution ② dropwise to the solution ③ to react to obtain a turbid solution, continue to stir for 0.5 hours after the addition, and control the entire reaction temperature at 0°C, and finally filter, wash and dry the obtained turbid solution , pulverized to obtain the compound salt ADXP, the ADXP whiteness is 96.

[0046] Or first dissolve 122g diethyl hypophosphorous acid and 611g sodium hexametaphosphate in 1000g water to obtain solution ①, then add 40g sodium hydroxide to solution ① to obtain the corresponding sodium salt mixture solution ②; Dissolve aluminum in 1000g water to obtain solution ③; add solution ③ dropwise to soluti...

Embodiment 2

[0048] 732g of diethyl hypophosphorous acid and 294g of aminotrimethylene phosphonic acid were simultaneously dissolved in 1500g of water to obtain a solution ④, and then 480g of sodium hydroxide was added into the solution ④ to obtain a corresponding sodium salt mixture solution ⑤; Dissolve aluminum in 5000g water to obtain solution ⑥; add solution ⑤ dropwise to solution ⑥ for reaction to obtain a turbid solution, continue stirring for 3 hours after the addition, control the entire reaction temperature at 50°C, and finally filter and wash the obtained turbid solution , dried, and pulverized to obtain the compound salt ADXP, and the whiteness of this ADXP is 97.

[0049] Or first 732g diethyl hypophosphorous acid and 294g aminotrimethylene phosphonic acid are dissolved in 1500g water to obtain a solution ④, then 480g sodium hydroxide is added to the solution ④ to obtain a corresponding sodium salt mixture solution ⑤; 1998g 18 Dissolve aluminum sulfate water in 5000g water to o...

Embodiment 3

[0051] Dissolve 244g of diethyl hypophosphorous acid and 43.6g of ethylenediamine tetramethylene phosphoric acid in 2000g of water simultaneously to obtain a solution ⑦, then add 112g of sodium hydroxide to the solution ⑦ to obtain the corresponding sodium salt mixture solution ⑧; Dissolve aluminum sulfate octahydrate in 2500g water to obtain solution ⑨; add solution ⑧ dropwise to solution ⑨ to react to obtain a turbid solution, continue to stir for 9 hours after the addition, and control the entire reaction temperature at 90°C. Finally, the obtained turbid solution Filter, wash, dry and pulverize to obtain the compound salt ADXP, and the whiteness of this ADXP is 95.

[0052] Or first dissolve 244g diethyl hypophosphorous acid and 43.6g ethylenediamine tetramethylene phosphoric acid in 2000g water to obtain solution ⑦, then add 112g sodium hydroxide to the solution ⑦ to obtain the corresponding sodium salt mixture solution ⑧; Dissolve 888g of aluminum sulfate octadecahydrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com