Graphene/carbon nanotube compound, conductive functional polymer and preparation method

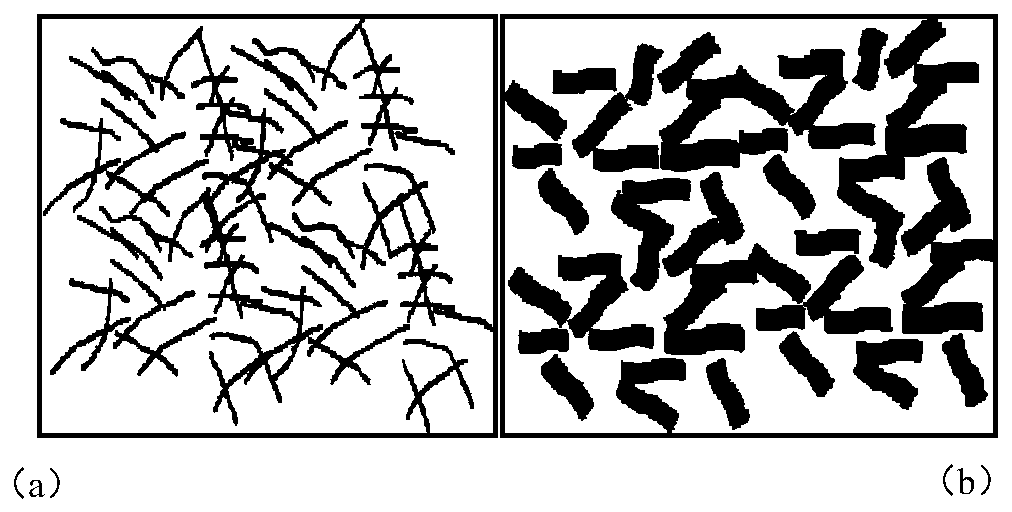

A technology of carbon nanotubes and graphene, which is applied in the field of carbon nanomaterials, can solve the problems of small apparent density, uneven dispersion, singleness, etc., and achieve the effect of improving quality and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

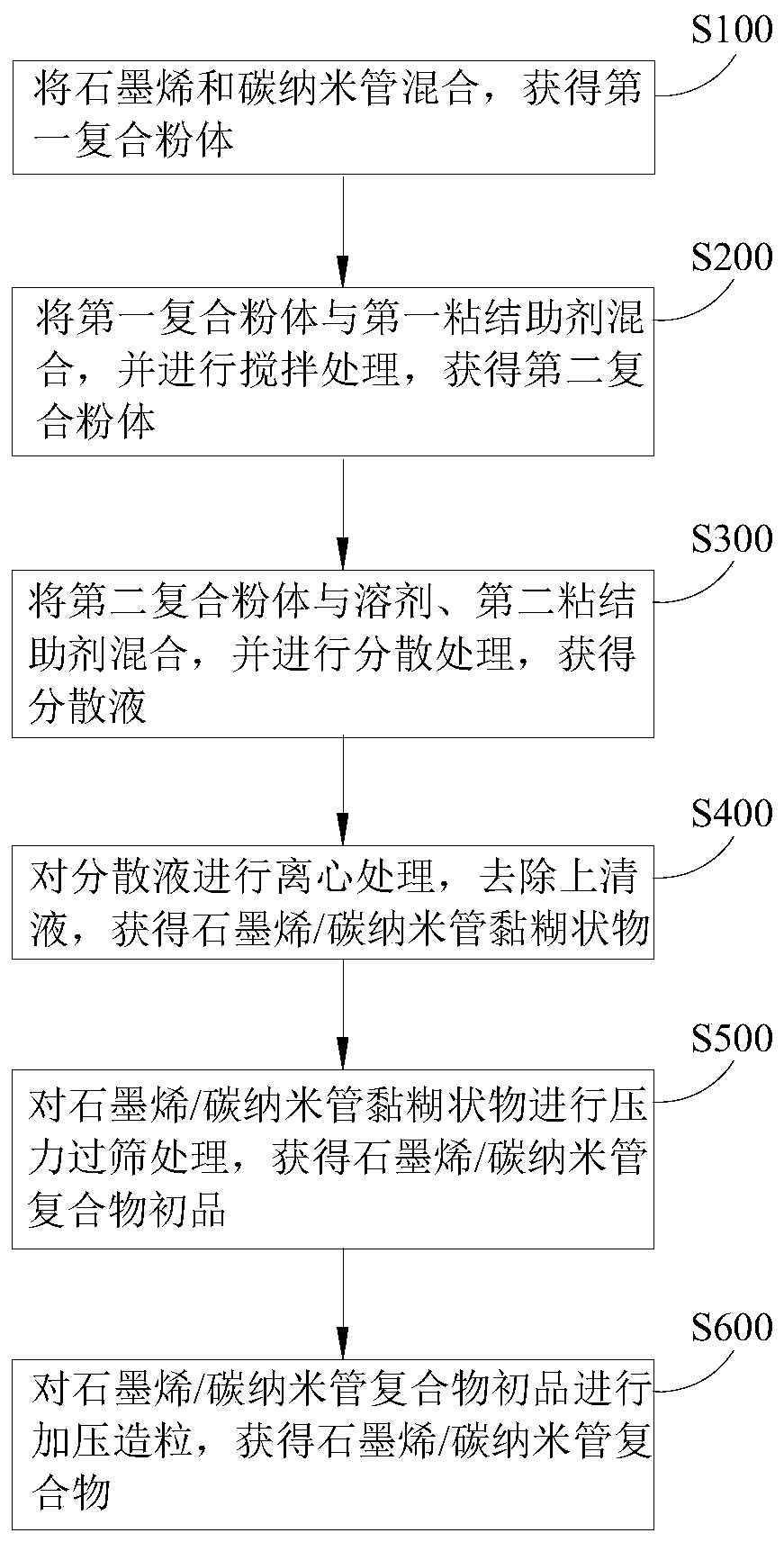

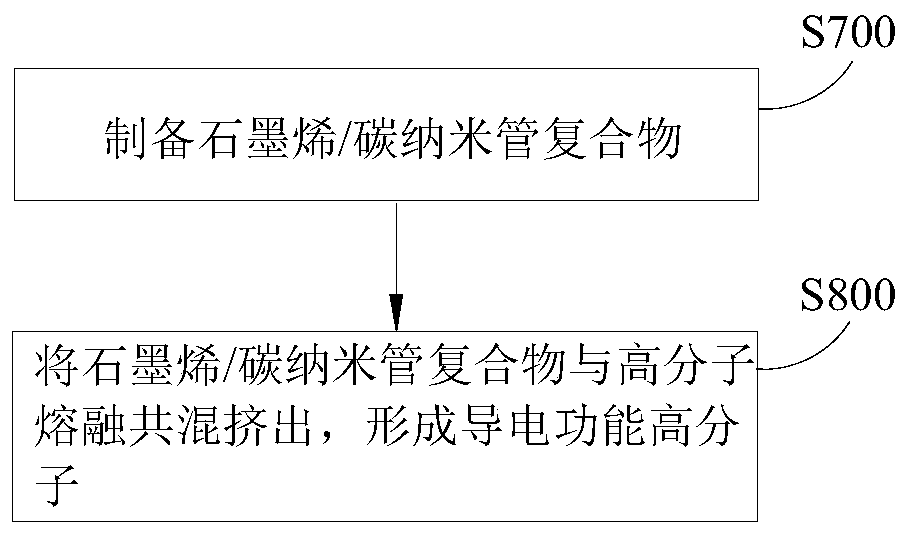

[0071] 1. Preparation of graphene / carbon nanotube composites:

[0072] (1) Mixing graphene powder and carbon nanotube powder in a ratio of 2:1 to obtain a first composite powder. Wherein, the graphene powder body takes 10g, and the carbon nanotube powder body takes 5g.

[0073] (2) Mix the first composite powder and polyethylene wax in a ratio of 1:1, that is, take 15g of polyethylene wax. Put the mixed first composite powder and polyethylene wax into a high-speed crushing mixer for high-speed stirring, the stirring speed is 2500r / min, the stirring time is 10s, and the temperature of the inner cavity of the mixer reaches 90°C during the stirring process. The apparent volume of the second composite powder obtained by high-speed stirring was reduced by nearly 30% compared with that before high-speed stirring.

[0074] (3) Take 200ml of absolute ethanol and mix it with the second composite powder, and add 30g of paraffin oil, and ultrasonically disperse for 1 hour to obtain a d...

Embodiment 2

[0084] 1. Preparation of graphene / carbon nanotube composites:

[0085] (1) Mix the graphene powder and the carbon nanotube powder at a ratio of 5:1 to obtain the first composite powder. Wherein, the graphene powder body takes 25g, and the carbon nanotube powder body takes 5g.

[0086] (2) Mix the first composite powder and polyethylene wax at a ratio of 1:3, that is, take 90g of polyethylene wax. Put the mixed first composite powder and polyethylene wax into a high-speed crushing mixer for high-speed stirring, the stirring speed is 2500r / min, the stirring time is 10s, and the temperature of the inner cavity of the mixer reaches 90°C during the stirring process. The apparent volume of the second composite powder obtained by high-speed stirring was reduced by nearly 50% compared with that before high-speed stirring.

[0087] (3) Mix 400ml of absolute ethanol with the second composite powder, add 60g of paraffin oil, and disperse by ball milling for 1 hour to obtain a dispersio...

Embodiment 3

[0097] 1. Preparation of graphene / carbon nanotube composites:

[0098] (1) Mixing the graphene powder and the carbon nanotube powder at a ratio of 1:5 to obtain the first composite powder. Wherein, the graphene powder body takes 5g, and the carbon nanotube powder body takes 25g.

[0099] (2) Mix the first composite powder and polyethylene wax at a ratio of 1:3, that is, take 90g of polyethylene wax. Put the mixed first composite powder and polyethylene wax into a high-speed crushing mixer for high-speed stirring, the stirring speed is 2500r / min, the stirring time is 10s, and the temperature of the inner cavity of the mixer reaches 90°C during the stirring process. The apparent volume of the second composite powder obtained by high-speed stirring was reduced by nearly 50% compared with that before high-speed stirring.

[0100] (3) Take 400ml of absolute ethanol and mix it with the second composite powder, and add 60g of paraffin oil, and ultrasonically disperse for 1 hour to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com