Hybrid modified melamine salt, preparation method and application thereof

A technology of melamine salt and melamine, which is applied in the field of hybrid modified melamine salt, can solve the problems of failing to improve the thermal stability of melamine salt, the thermal decomposition temperature is not significantly improved, the mechanical properties are retained, and the like, so as to avoid a large number of problems. Oxidation, increase special effect, increase the effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A hybrid modified melamine salt, the preparation steps of which are as follows:

[0049] (1) Preparation of amino-rich graphitic carbon nitride nanosheets:

[0050] 1) First heat the melamine to 330°C at a heating rate of 2°C / min and keep it warm for 2 hours;

[0051] 2) Then raise the temperature to 480°C at a heating rate of 2°C / min and keep it warm for 2h;

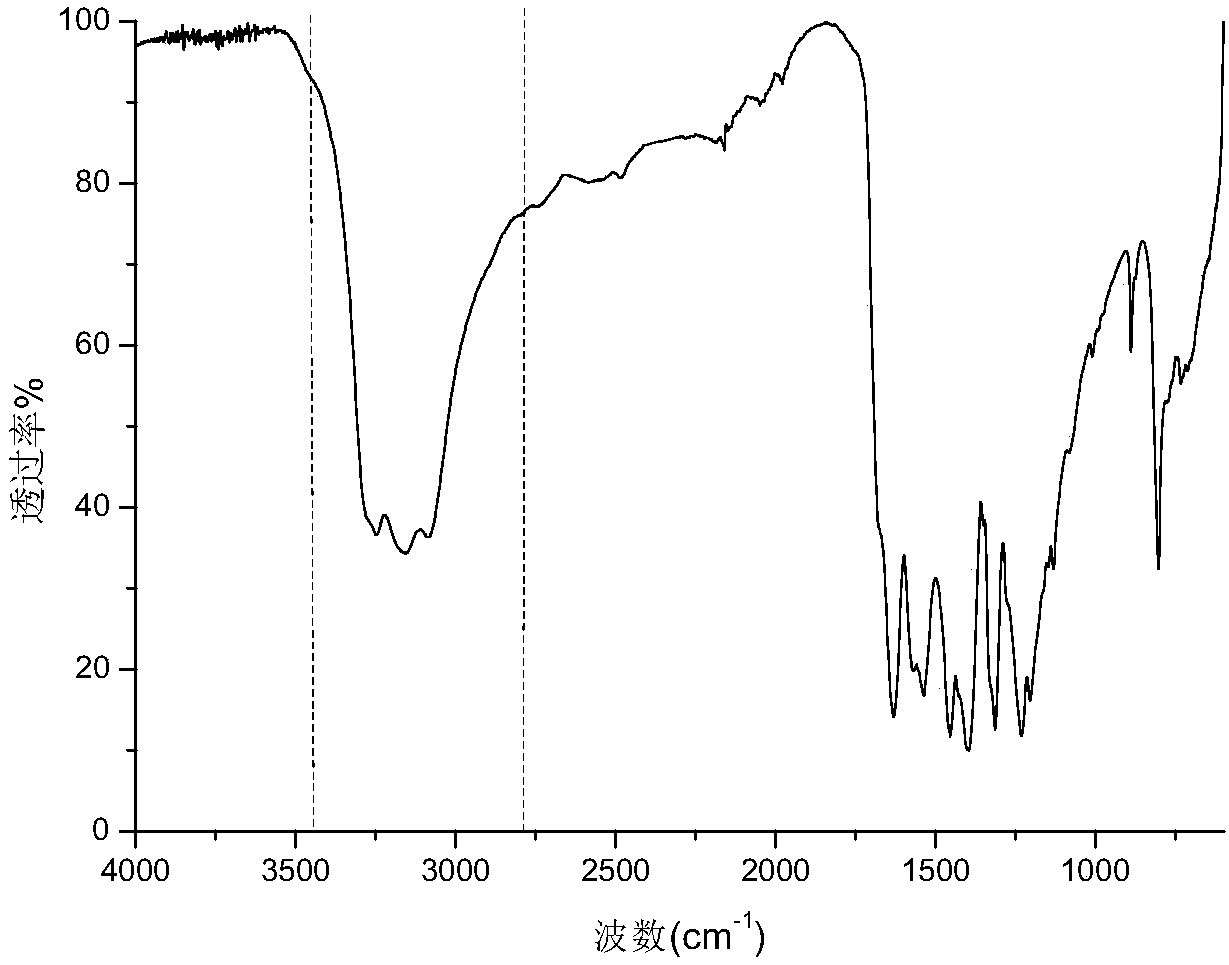

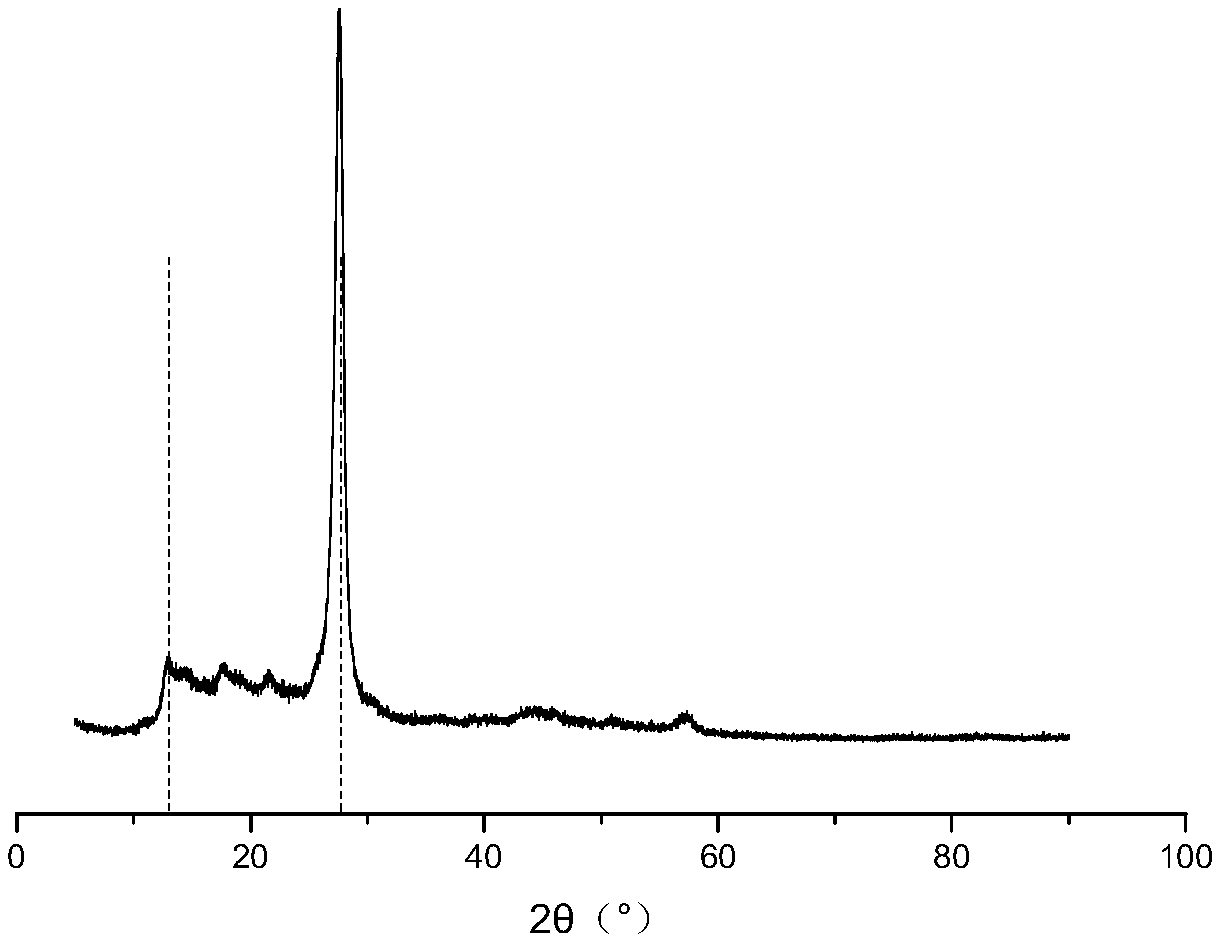

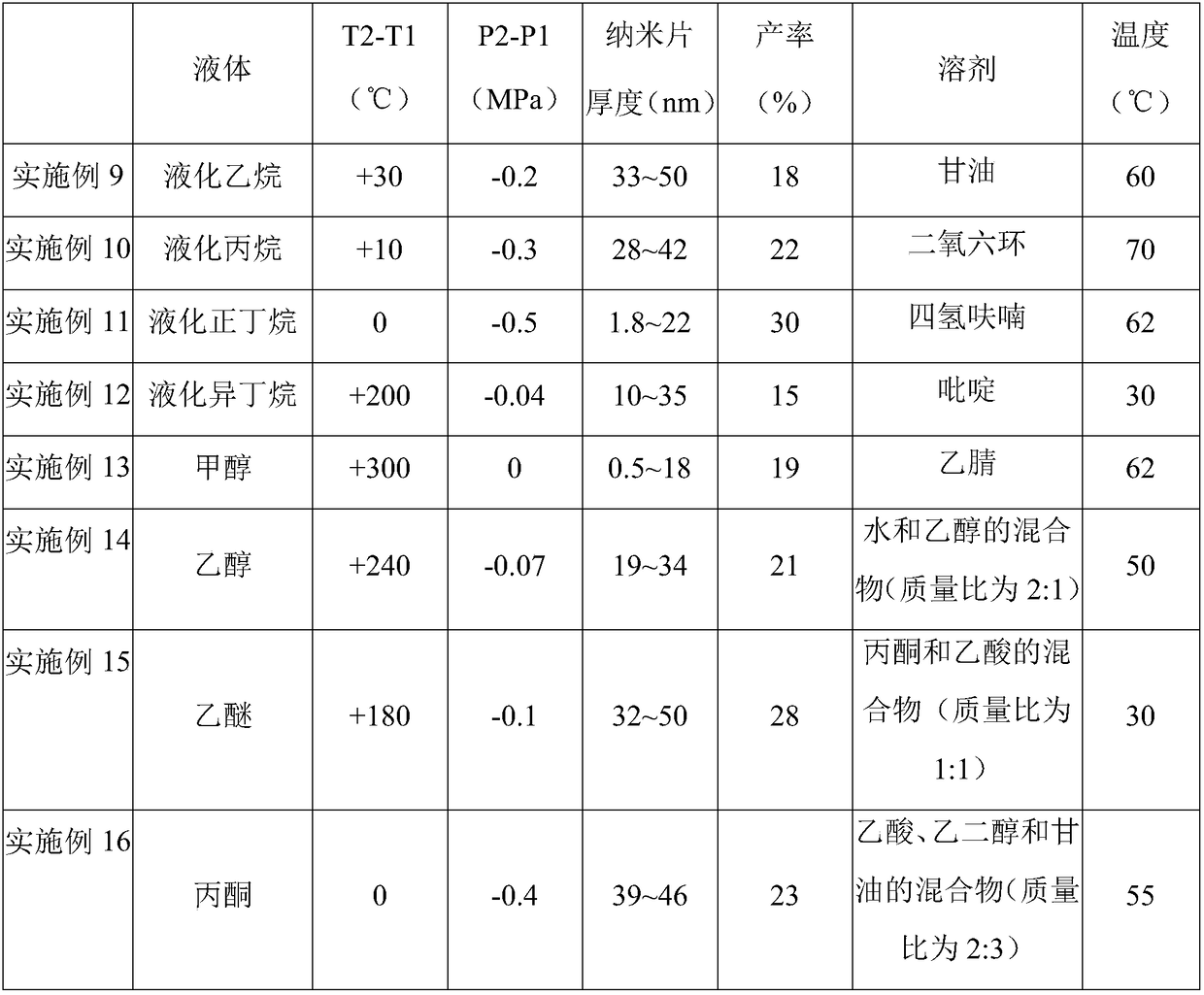

[0052] 3) Then raise the temperature to 500° C. at a heating rate of 2° C. / min and keep it warm for 2 hours to obtain amino-rich graphite carbon nitride; the nitrogen content of the prepared amino-rich graphite carbon nitride is 66.5 wt%. Its chemical structure is rich in amino groups, such as figure 1 The shown Fourier transform infrared spectrum is at 2700-3400cm -1 It can be proved by the broad absorption peak at the position that the prepared amino-rich graphitic carbon nitride contains a graphite-like structure, which can also be proved by the sharp peaks near 13.5° and 27.5° in the X-ray diffraction patt...

Embodiment 2

[0060] A hybrid modified melamine salt, the preparation steps of which are as follows:

[0061] (1) Preparation of amino-rich graphitic carbon nitride nanosheets:

[0062] 1) First heat dicyandiamine to 350°C at a heating rate of 22°C / min and keep it warm for 5 hours;

[0063] 2) Then raise the temperature to 490°C at a heating rate of 19°C / min and keep it warm for 8 hours;

[0064] 3) Then raise the temperature to 530° C. at a heating rate of 11.5° C. / min and keep it warm for 9 hours to obtain amino-rich graphite carbon nitride; the nitrogen element content of the prepared amino-rich graphite carbon nitride is 67.3 wt%. Its chemical structure is rich in amino groups, and the obtained amino-rich graphite carbon nitride contains graphite-like structures;

[0065] 4) Completely immerse the amino-rich graphite carbon nitride in liquid oxygen and maintain the temperature T1 and maintain the pressure P1 for 22 minutes;

[0066] 5) Take out the amino-rich graphite carbon nitride ...

Embodiment 3

[0072] A hybrid modified melamine salt, the preparation steps of which are as follows:

[0073] (1) Preparation of amino-rich graphitic carbon nitride nanosheets:

[0074] 1) First heat cyanamide to 300°C at a heating rate of 5°C / min and keep it warm for 6 hours;

[0075] 2) Then raise the temperature to 400°C at a heating rate of 3.5°C / min and keep it warm for 10 hours;

[0076] 3) Then raise the temperature to 550° C. at a heating rate of 18° C. / min and keep it warm for 2 hours to obtain amino-rich graphitic carbon nitride; the nitrogen content of the prepared amino-rich graphitic carbon nitride is 66 wt%. The chemical structure is rich in amino groups, and the prepared amino-rich graphitic carbon nitride contains a graphite-like structure.

[0077] 4) Completely immerse the amino-rich graphite carbon nitride in liquid helium and maintain the temperature T1 and maintain the pressure P1 for 18 minutes;

[0078] 5) Take out the amino-rich graphite carbon nitride and place i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com