A kind of amino-rich graphitic carbon nitride and preparation method thereof

A graphitic carbon nitride, amino-rich technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen-metal/silicon/boron binary compounds, etc., can solve problems such as limiting the scope of application, increasing special functions, and low amino content , to achieve the effect of expanding the scope of application, reducing the degree of thermal oxidation, and increasing the content of amino groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of amino-rich graphitic carbon nitride, the steps are as follows:

[0033] 1) First heat cyanamide to 330°C at a heating rate of 13.5°C / min and keep it warm for 10 hours;

[0034] 2) Then raise the temperature to 480°C at a heating rate of 12°C / min and keep it warm for 11 hours;

[0035] 3) Then raise the temperature to 500°C at a heating rate of 0.5°C / min and keep it warm for 3 hours;

[0036] 4) The final collected product is amino-rich graphitic carbon nitride.

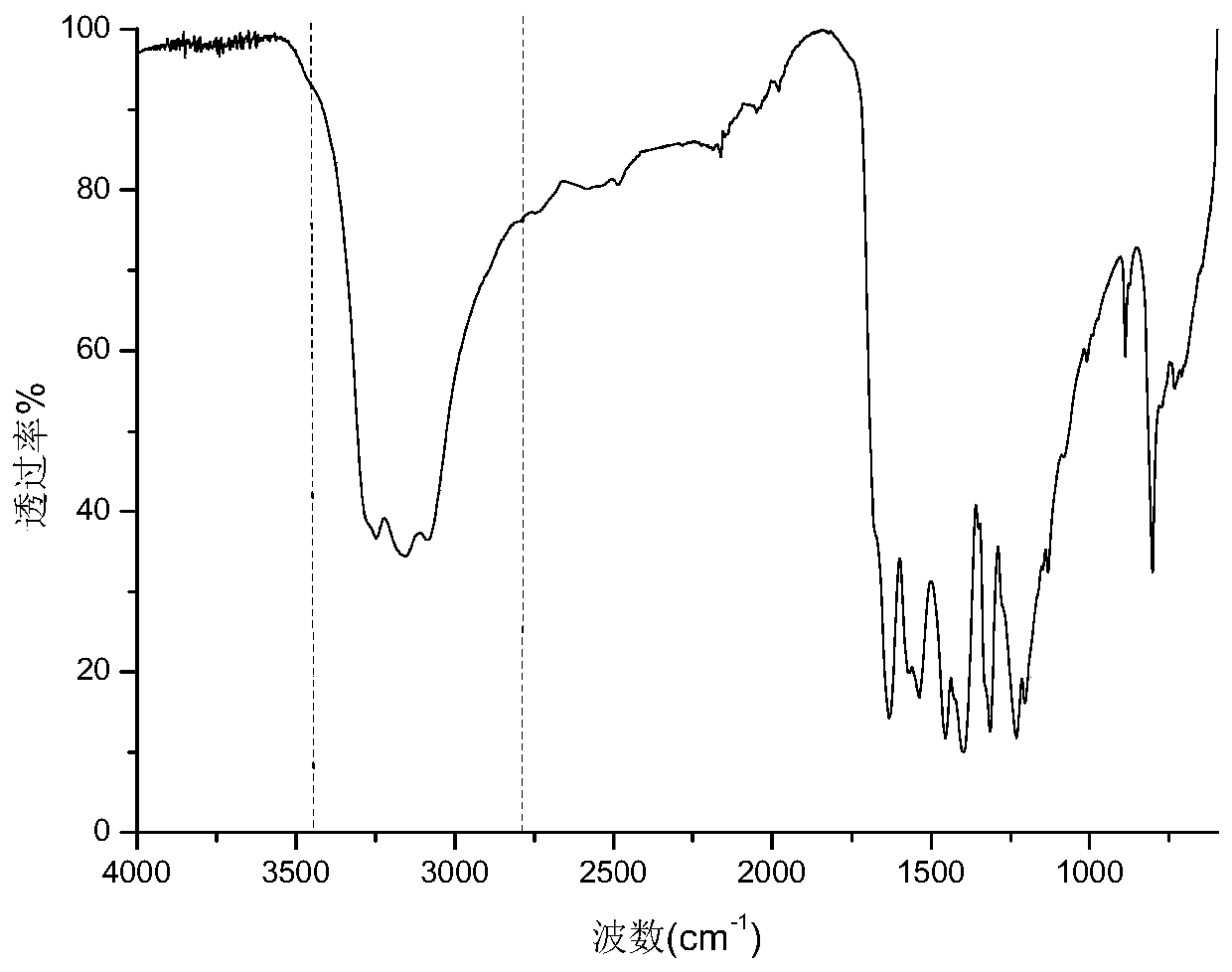

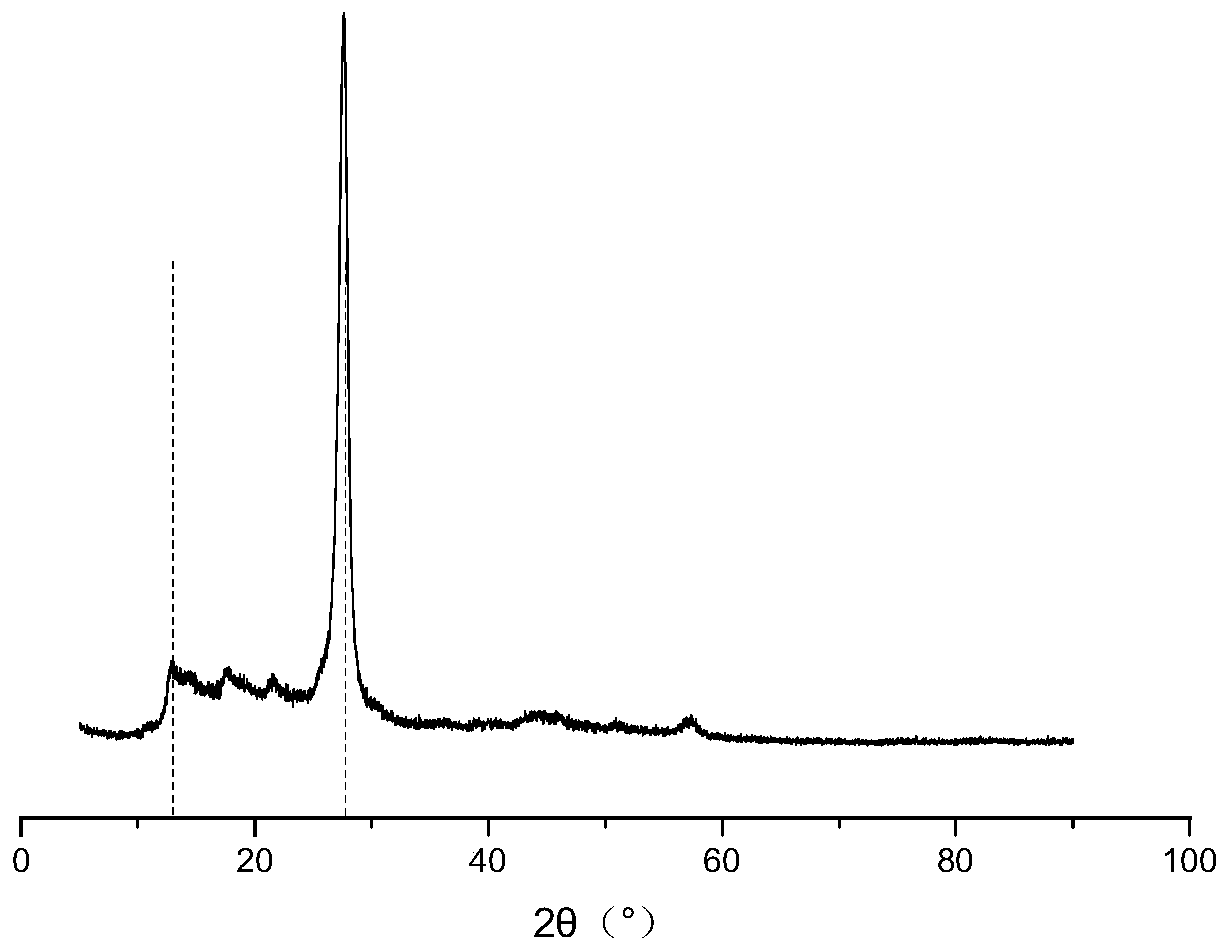

[0037] The nitrogen content of the obtained amino-rich graphitic carbon nitride is 66.5wt%, and its chemical structure is rich in amino groups, such as figure 1 The shown Fourier transform infrared spectrum is at 2700-3400cm -1 It can be proved by the broad absorption peak at the position that the prepared amino-rich graphitic carbon nitride contains a graphite-like structure, which can also be proved by the sharp peaks near 13.5° and 27.5° in the X-ray diffraction pattern, such as ...

Embodiment 2

[0039] A preparation method of amino-rich graphitic carbon nitride, the steps are as follows:

[0040] 1) First heat dicyandiamine to 350°C at a heating rate of 22°C / min and keep it warm for 5 hours;

[0041] 2) Then raise the temperature to 490°C at a heating rate of 19°C / min and keep it warm for 8 hours;

[0042] 3) Then raise the temperature to 530°C at a heating rate of 11.5°C / min and keep it warm for 9 hours;

[0043] 4) The final collected product is amino-rich graphitic carbon nitride.

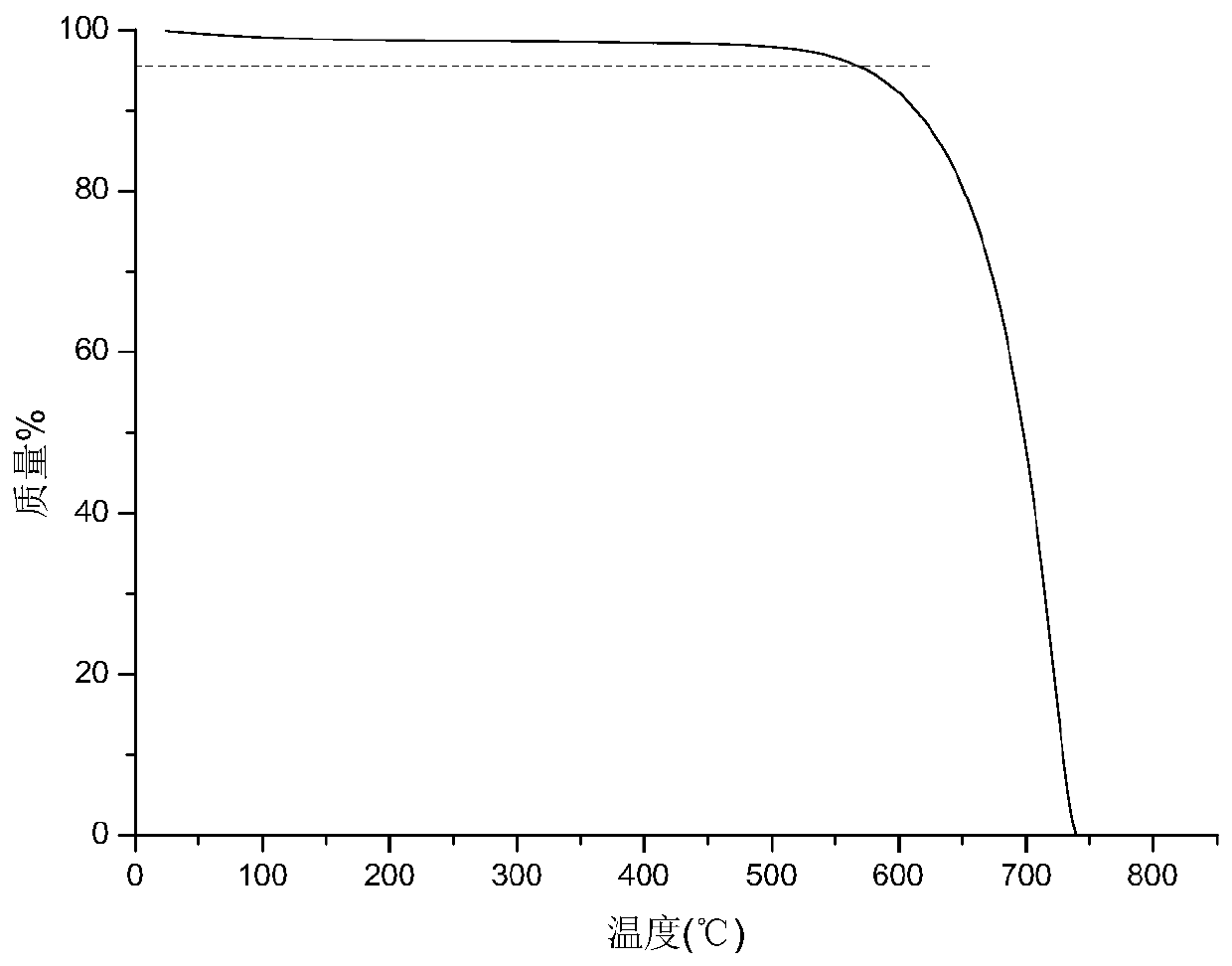

[0044] The nitrogen element content of the prepared amino-rich graphitic carbon nitride is 67.3 wt%, and its chemical structure is rich in amino groups, and the prepared amino-rich graphitic carbon nitride has a graphite-like structure. In addition, the 5wt% thermal weight loss temperature of the prepared amino-rich graphitic carbon nitride is 592°C.

Embodiment 3

[0046] A preparation method of amino-rich graphitic carbon nitride, the steps are as follows:

[0047] 1) First heat the melamine to 300°C at a heating rate of 5°C / min and keep it warm for 6 hours;

[0048]2) Then raise the temperature to 400°C at a heating rate of 3.5°C / min and keep it warm for 10 hours;

[0049] 3) Then raise the temperature to 550°C at a heating rate of 18°C / min and keep it warm for 2 hours;

[0050] 4) The final collected product is amino-rich graphitic carbon nitride.

[0051] The nitrogen element content of the prepared amino-rich graphitic carbon nitride is 66 wt%, and its chemical structure is rich in amino groups, and the prepared amino-rich graphitic carbon nitride contains a graphite-like structure. In addition, the 5wt% thermal weight loss temperature of the prepared amino-rich graphitic carbon nitride is 586°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com