High-elasticity gasket for high-voltage transmission line clamp and preparation method thereof

A technology of high-voltage transmission lines and gaskets, applied in transportation and packaging, metal processing equipment, cable suspension devices, etc., can solve problems such as damage to mechanical properties, changes in phase transition process, difficulties, etc., to reduce the degreasing temperature and avoid a large number of Oxidation, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

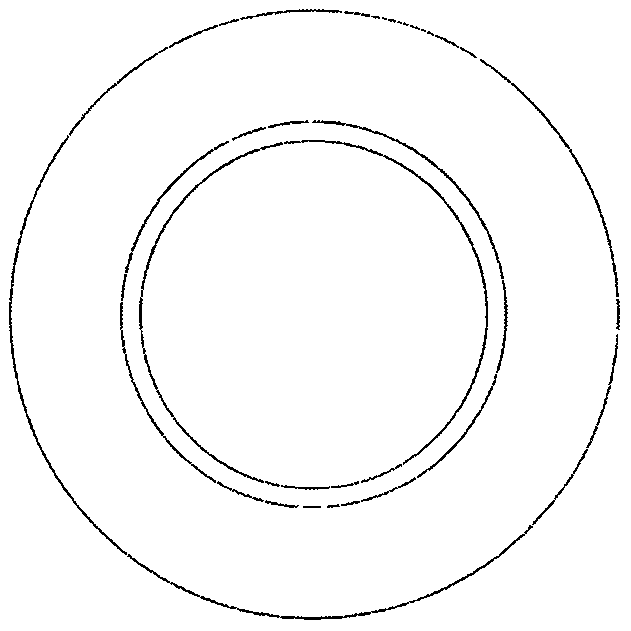

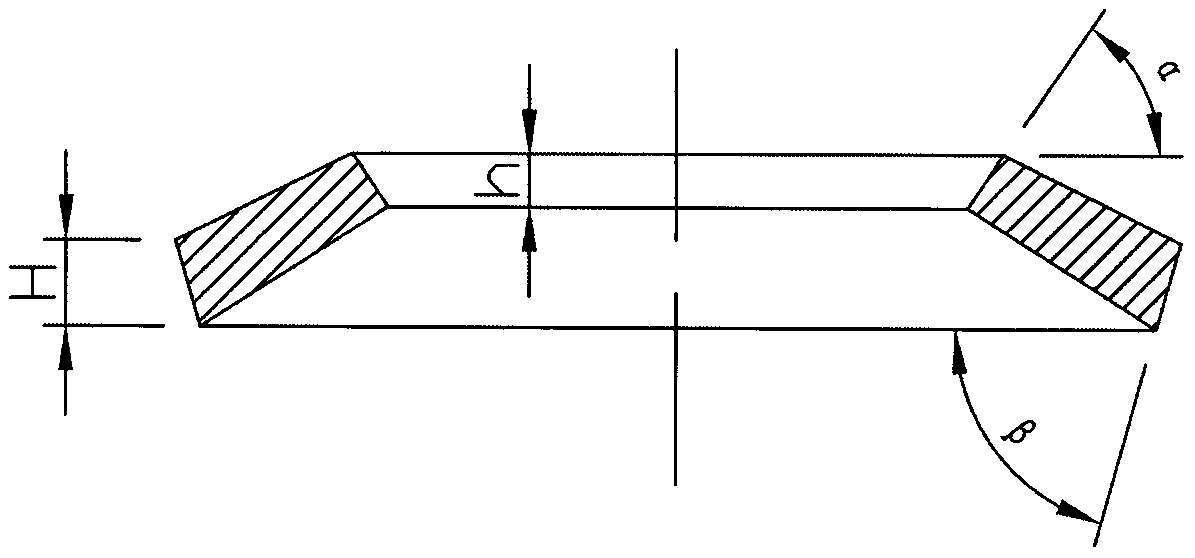

[0025] Such as figure 1 and figure 2 As shown, the gasket is made of NiTi alloy material, where the atomic percentage of Ni is 49.5, the shape of the gasket is circular, the ratio of the height of the outer ring (H) to the height of the inner ring (h) is 1.2, and the surface of the gasket is along the diameter direction Extended to a plane, the chamfer β of the outer edge of the gasket ring is 35°, and the chamfer α of the edge of the ring hole is 30°. Figure 4 Schematic diagram of the cross-sectional structure of the high-elastic gasket used for the high-voltage transmission line clamp under the loaded state and flattened.

[0026] Its preparation method includes:

[0027] (1) Powder and binder preparation: the average particle size of the NiTi pre-alloyed powder is 15 μm, the main component is Ti-x Ni (atomic percentage), wherein x=49.5, and the total amount of impurities is 0.2wt.%. Combining water base and plastic base resin, the main components (mass percentage) are:...

Embodiment 2

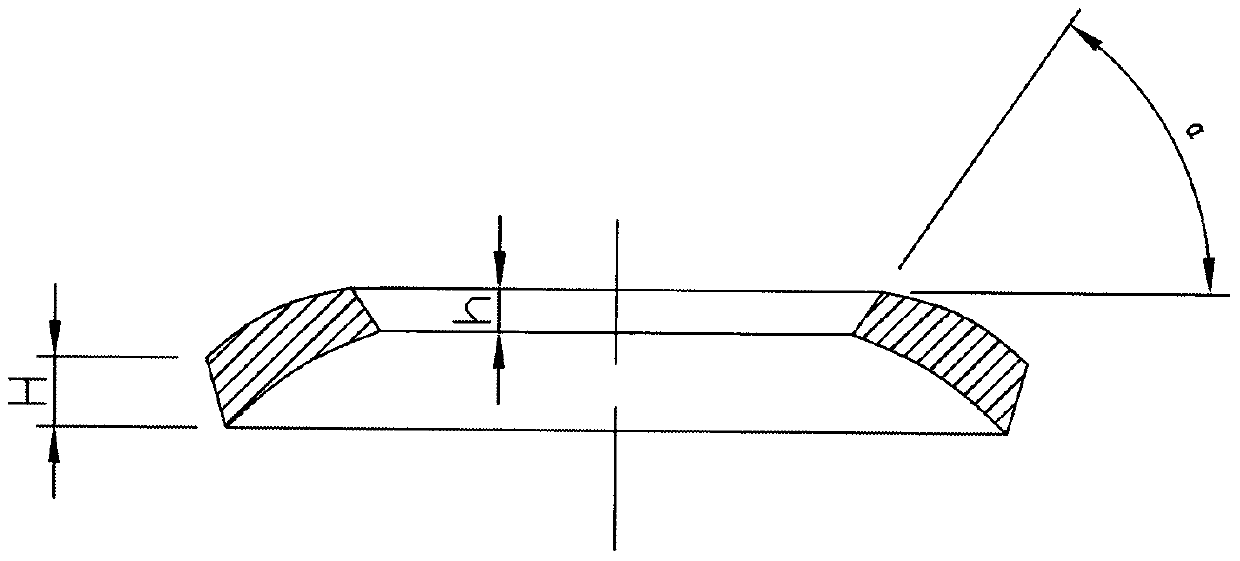

[0035] The gasket is made of NiTi alloy material, in which the atomic percentage of Ni is 50.0, the gasket is in the shape of a ring, and the ratio of the height of the outer ring (H) to the height of the inner ring (h) is H / h=1.7; image 3As shown, the surface of the gasket expands into a parabolic surface along the diameter direction; the chamfer β of the outer edge of the gasket ring is 60°, and the chamfer α of the ring hole edge is 53°; other dimensions of the gasket are designed according to the actual service clamp standard.

[0036] Its preparation method includes:

[0037] (1) Powder and binder preparation: the average particle size of the NiTi pre-alloyed powder is 20 μm, the main component is Ti-x Ni (atomic percentage), wherein x=50.0, and the total amount of impurities is 0.2wt.%. Combining water base and plastic base resin, the main components (mass percentage) are: polyethylene glycol 35%, polyoxymethylene 60%, polypropylene 3%, ethylene-ethylene acetic acid cop...

Embodiment 3

[0045] The high-elastic gasket for high-voltage transmission line clip of the present invention adopts NiTi alloy material, wherein the atomic percentage of Ni is 49.8, and the gasket is in the shape of a ring, and the ratio of the height of the outer ring (H) to the height of the inner ring (h), H / h=1.8; the surface of the gasket expands into a plane along the diameter direction; the chamfer β of the outer edge of the gasket ring is 35°, and the chamfer α of the ring hole edge is 30°.

[0046] Its preparation method includes:

[0047] (1) Powder and binder preparation: the average particle size of the NiTi pre-alloyed powder is 20 μm, the main component is Ti-x Ni (atomic percentage), wherein x=49.8, and the total amount of impurities is 0.1wt.%. Combining water base and plastic base resin, the main components (mass percentage) are: polyethylene glycol 20%, polyoxymethylene 60%, polypropylene 15%, ethylene-ethylene acetic acid copolymer 5%;

[0048] (2) Mixing. Under the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Phase transition peak temperature | aaaaa | aaaaa |

| Phase transition peak temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com