Manufacturing method of mobile phone oscillator

A vibrator, mobile phone technology, applied to other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of large aspect ratio, unfriendly environment, long heat preservation time, etc., to achieve the improvement of the crushing strength of the middle hole, and improve the comprehensive Mechanical properties, the effect of reducing the holding time of degreasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

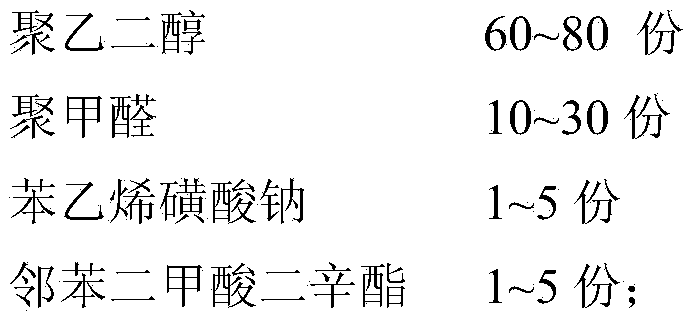

[0025] Preparation of adhesive: mix adhesive containing 74 parts by weight of polyethylene glycol, 24 parts by weight of polyoxymethylene, 1 part by weight of sodium styrene sulfonate, and 1 part by weight of dioctyl phthalate at 140 °C for 40 minutes.

[0026] Mix the tungsten-based alloy powder with the binder: mix the tungsten-based alloy powder and the binder with a mass ratio of 25-1 for 1 hour; wherein the tungsten-based alloy powder contains 93 parts by weight of tungsten, 5 parts by weight Nickel, 2 parts by weight of copper.

[0027] Compression molding: put the mixture of the tungsten-based alloy powder and the binder into the corresponding mold, and press it with a pressure of 10KN to form a blank.

[0028] Degreasing: put the billet into a degreasing device and raise the temperature to 70° C. and keep it warm for 2 hours.

[0029] Sintering: firstly sinter the degreased blank in a microwave oven at 1375°C under the protection of nitrogen, and keep it warm for 40 ...

Embodiment 2

[0031] Preparation of adhesive: mix adhesive containing 76 parts by weight of polyethylene glycol, 22 parts by weight of polyoxymethylene, 1 part by weight of sodium styrene sulfonate, and 1 part by weight of dioctyl phthalate at 140 °C for 40 minutes.

[0032] Mix the tungsten-based alloy powder with the binder: mix the tungsten-based alloy powder and the binder with a mass ratio of 35:1 for 1 hour; wherein the tungsten-based alloy powder contains 95 parts by weight of tungsten, 2 parts by weight Nickel, 3 parts by weight of copper.

[0033] Compression molding: Put the mixture of the tungsten-based alloy powder and the binder into a corresponding mold, and press it with a pressure of 15KN to form a blank.

[0034] Degreasing: put the billet into a degreasing device and raise the temperature to 75° C. and keep it warm for 2 hours.

[0035] Sintering: firstly sinter the degreased blank in a microwave oven at 1410°C under the protection of nitrogen, and keep it warm for 30 mi...

Embodiment 3

[0037] Preparation of adhesive: mix adhesive containing 75 parts by weight of polyethylene glycol, 23 parts by weight of polyoxymethylene, 1 part by weight of sodium styrene sulfonate, and 1 part by weight of dioctyl phthalate at 140 °C for 40 minutes.

[0038] Mix the tungsten-based alloy powder with the binder: mix the tungsten-based alloy powder and the binder with a mass ratio of 45:1 for 1 hour; wherein the tungsten-based alloy powder contains 95 parts by weight of tungsten, 3 parts by weight of Nickel, 2 parts by weight of copper.

[0039] Compression molding: Put the mixture of the tungsten-based alloy powder and the binder into the corresponding mold, and press it with a pressure of 20KN to form a blank.

[0040] Degreasing: put the billet into a degreasing device and raise the temperature to 70° C. and keep it warm for 2.5 hours.

[0041] Sintering: first sinter the degreased blank in a microwave oven at 1450°C under the protection of nitrogen, and keep it warm for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com