WC-Co-RE compound powder and preparation method and application thereof

A composite powder, wc-co-re technology, applied in the field of cemented carbide, can solve the problems of uneven dispersion, lower thermoplasticity and toughness, uneven distribution of rare earth elements, etc., to improve mixing uniformity, reduce grain size, Avoid the effects of massive oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

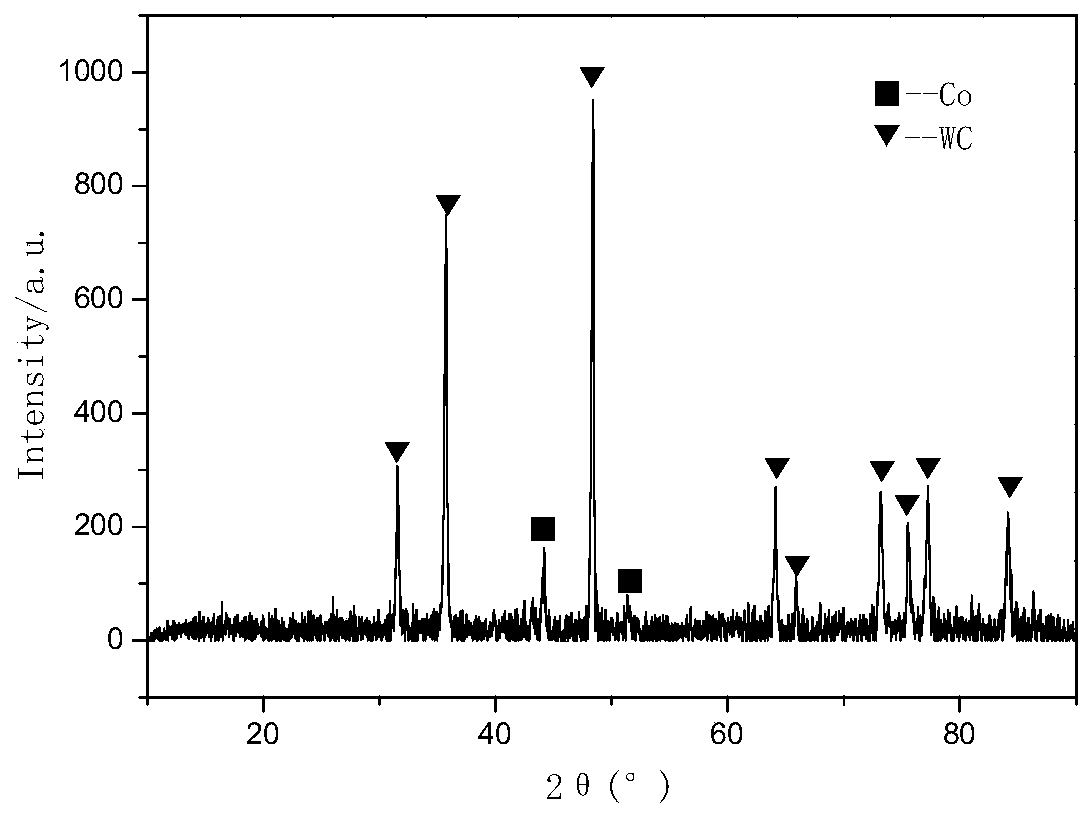

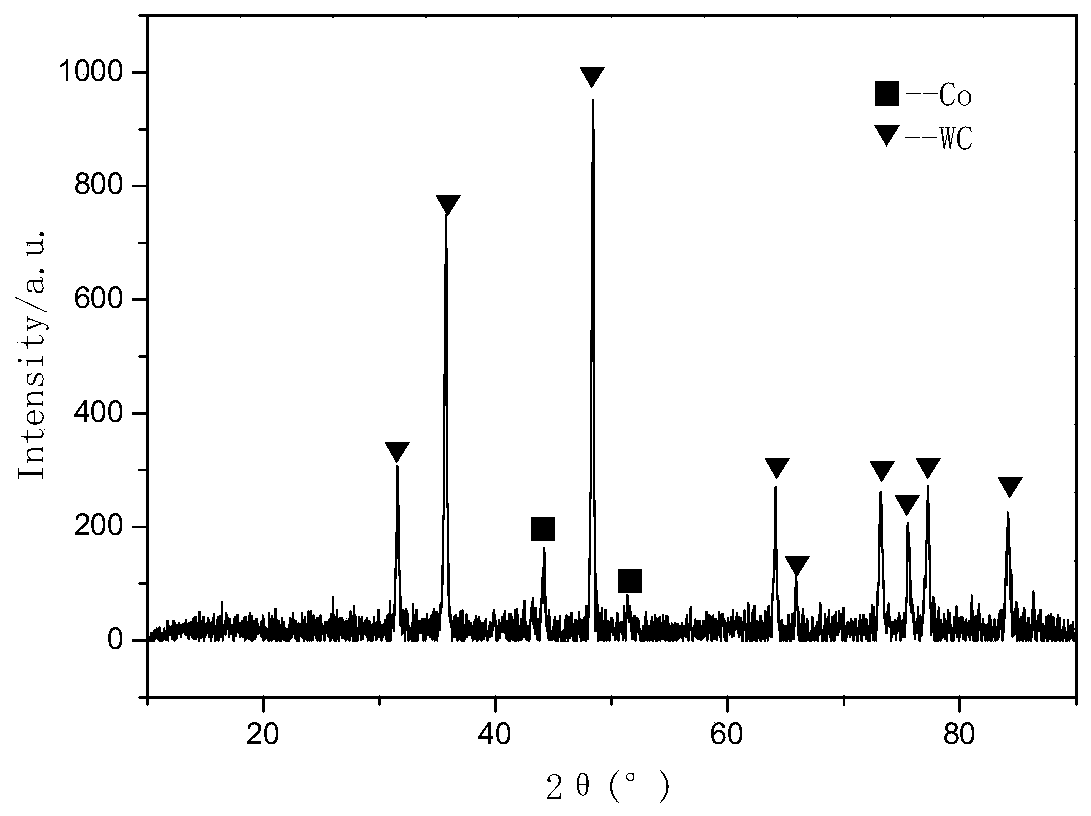

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of WC-Co-RE composite powder, comprising the following steps:

[0026] mixing the soluble cobalt salt solution and the soluble rare earth salt solution to obtain a mixed solution;

[0027] Adjusting the ammonium tungstate aqueous solution to acidity, carbon powder and the mixed solution undergo precipitation reaction, and then dry to obtain the mixed powder;

[0028] In a protective atmosphere, the mixed powder is decomposed and reduced sequentially, and cooled to obtain a WC-Co-RE composite powder.

[0029] The invention mixes the soluble cobalt salt aqueous solution and the soluble rare earth salt aqueous solution to obtain a mixed solution.

[0030] In the present invention, the mass ratio of the cobalt element in the soluble cobalt salt solution to the rare earth element in the soluble rare earth salt solution is preferably 3-30: 0.1-0.6, more preferably 10-20: 0.2-0.5; There is no special requirement for the mixing cond...

Embodiment 1

[0055] Prepare the metal composite powder of WC-10%Co-0.1%Y (the mass percentage content of each element in the powder is: 10%Co, 0.1%Y, and the rest is WC), and weigh the corresponding mass of ammonium tungstate, Cobalt nitrate, yttrium nitrate and carbon powder, the specific surface area of carbon powder is 1200m 2 / g.

[0056] The cobalt nitrate solution and the yttrium nitrate solution are mixed to obtain a mixed solution. Dissolve ammonium tungstate in water to obtain ammonium tungstate solution, heat the ammonium tungstate solution to 80°C and stir, use HNO 3 Adjust the pH value to 5, then add the weighed carbon powder into the ammonium tungstate, then slowly add the mixed solution into the ammonium tungstate solution containing carbon powder, and add dropwise while stirring until the precipitation reaction is completed (after the dropwise addition is complete A total of 5h until the reaction is complete), a suspension or a paste is obtained, and the suspension or pa...

Embodiment 2

[0060] Prepare the composite powder of WC-6%Co-0.1%Y-0.1%Ce (the mass percentage content of each element in the powder is: 6%Co, 0.1%Y, 0.1%Ce, and the rest of WC), and weigh the corresponding Quality ammonium tungstate, cobalt nitrate, yttrium nitrate, cerium nitrate and carbon powder, the specific surface area of the carbon powder is 1300m 2 / g.

[0061] The cobalt nitrate aqueous solution, the yttrium nitrate aqueous solution and the cerium nitrate aqueous solution are mixed to obtain a mixed solution. Dissolve ammonium tungstate in water to obtain ammonium tungstate solution, heat the ammonium tungstate solution to 90°C and stir, use HNO 3 Adjust the pH value to 6, then add the weighed carbon powder into the ammonium tungstate, then slowly add the mixed solution into the ammonium tungstate solution containing carbon powder, and add dropwise while stirring until the precipitation reaction is completed (after the dropwise addition is complete A total of 3h until the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com