Triazine compound, as well as preparation method and application thereof

A compound and triazine technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of low thermal stability of products, large amount of organic solvents, and difficulty in subsequent processing. and other problems, to avoid excessive reaction time, less side reactions, and facilitate industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

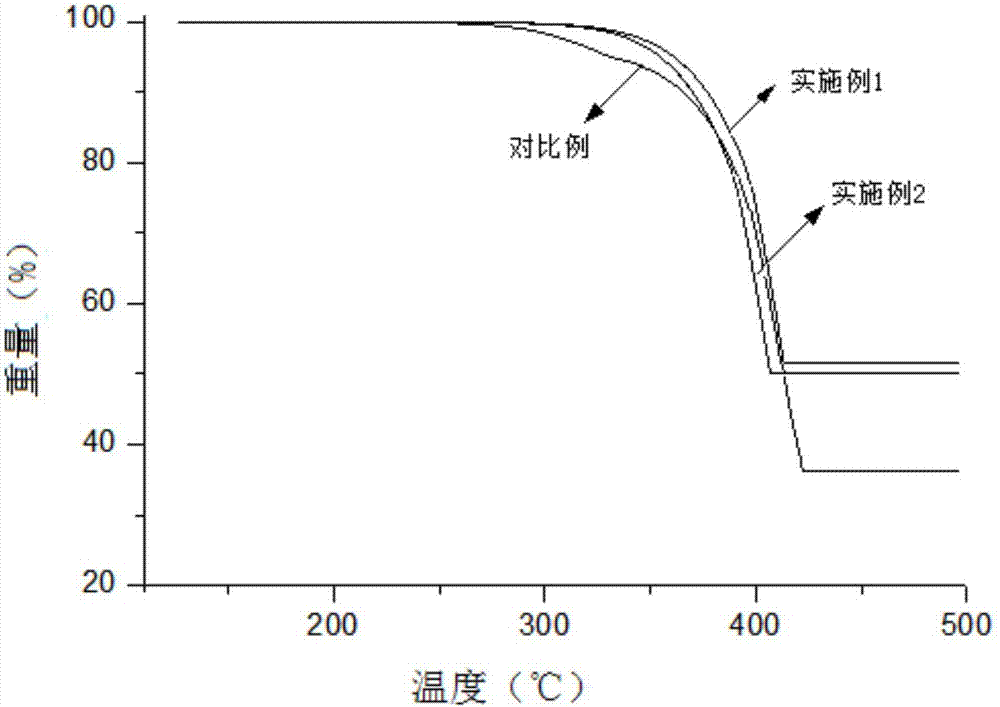

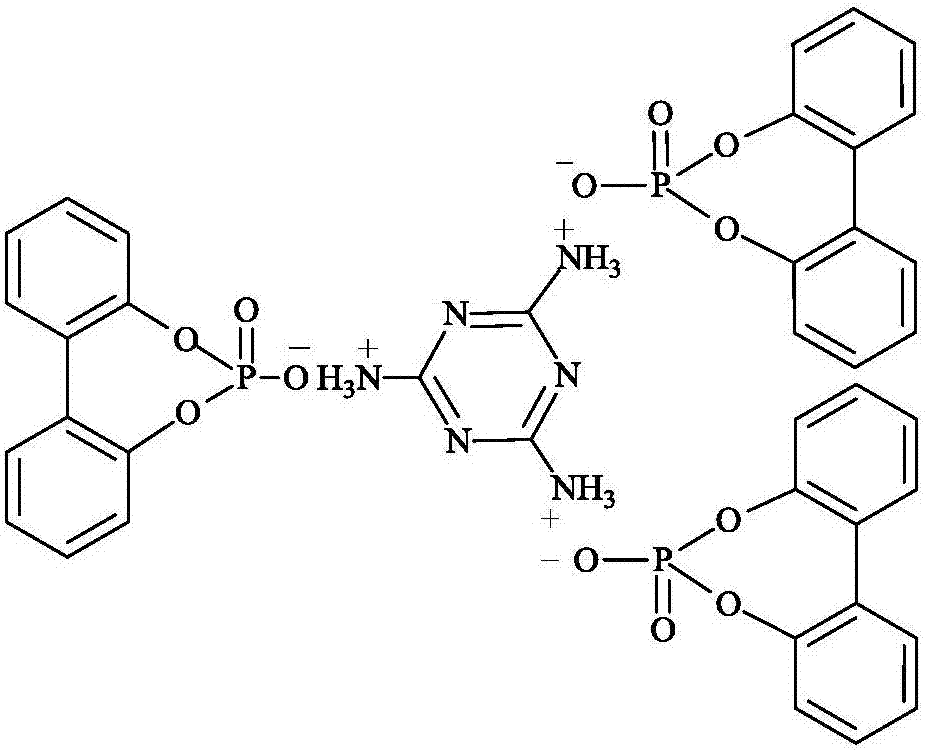

[0034] Add 188.0g (1mol) of 2,2'-dihydroxybiphenyl (99.0%), 433.0g of toluene (99.5%) to a 2L four-necked round-bottomed flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, 132.9g (1.3mol) of triethylamine (content 99.0%), start stirring, control the temperature at 10°C, add 155.6g (1mol) (98.5%) of phosphorus oxychloride dropwise for 1.0h, and continue the reaction for 4h. Rotary steam toluene, add 800g water, 37.9g (0.3mol) melamine (99.8%), cool down after 100 ℃ of reflux reaction 3h, filter, dry, obtain product 801.1g, calculate yield 96.0% with phosphorus oxychloride, heat The amount of carbon formed at 500°C by gravimetric analysis is 51.8%, and the thermal decomposition temperature is 305°C.

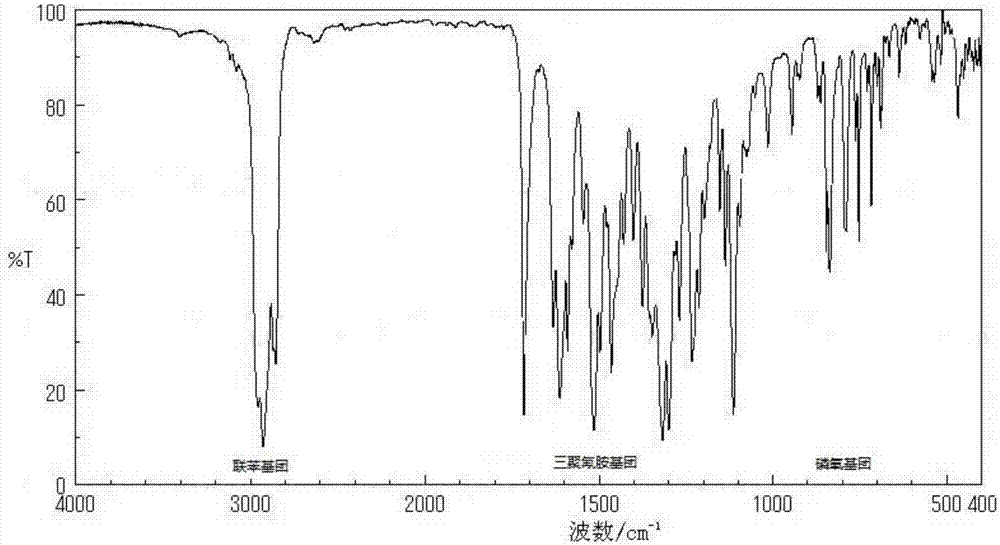

[0035] figure 1 It is the infrared spectrogram of embodiment 1 gained triazine compound, from figure 1 It can be seen that there are melamine groups (1650~1000cm -1 ), biphenyl group (3500~2800cm -1 ) and phosphorus oxygen group (600~750cm ...

Embodiment 2

[0037] Add 225.6g (1.2mol) of 2,2'-dihydroxybiphenyl (99.0%) and 433.0g of toluene (99.5%) to a 2L four-necked round-bottomed flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel , 112.4g (1.1mol) triethylamine (content 99.0%), start stirring, control the temperature at 10°C, add 155.6g (1mol) (98.5%) of phosphorus oxychloride dropwise for 1.5h, and continue the reaction for 5h. Rotary steam toluene, add 800g of water, 39.1g of melamine (0.31mol) (99.8%), reflux at 100°C for 3.5h, then cool down, filter, and dry to obtain 821.5g of the product, with a yield of 98.5% based on phosphorus oxychloride. According to thermogravimetric analysis, the amount of carbon formed at 500°C is 50.2%, and the thermal decomposition temperature is 304°C.

Embodiment 3

[0039] Add 188.0g (1mol) of 2,2'-dihydroxybiphenyl (99.0%), 433.0g of toluene (99.5%) to a 2L four-necked round-bottomed flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, 102.2g (1mol) of triethylamine (content 99.0%), start stirring, control the temperature at 10°C, add 155.6g (1mol) (98.5%) of phosphorus oxychloride dropwise for 3h, and continue the reaction for 7h. Rotary steam toluene, add 800g of water, 37.9g (0.3mol) of melamine (99.8%), reflux at 100°C for 5h, cool down, filter, and dry to obtain 809.8g of the product, with a yield of 97.1% based on phosphorus oxychloride. According to thermogravimetric analysis, the amount of carbon formed at 500°C is 50.2%, and the thermal decomposition temperature is 304°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com