Catalysis carbonization intumescent flame-retardant system and application thereof

An intumescent flame retardant system technology, applied in the direction of flame retardant fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of secondary damage, failure to meet the requirements of flame retardant performance, etc., achieve good flame retardant performance, reduce heat Release rate, effect of reducing total heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

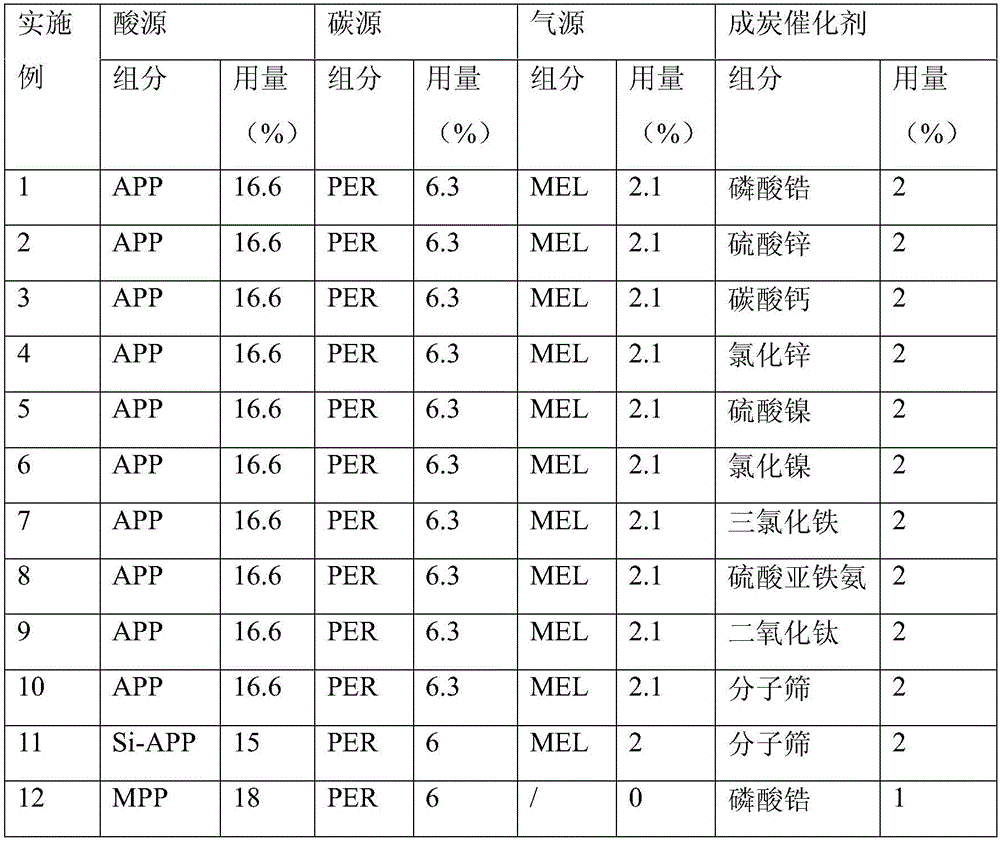

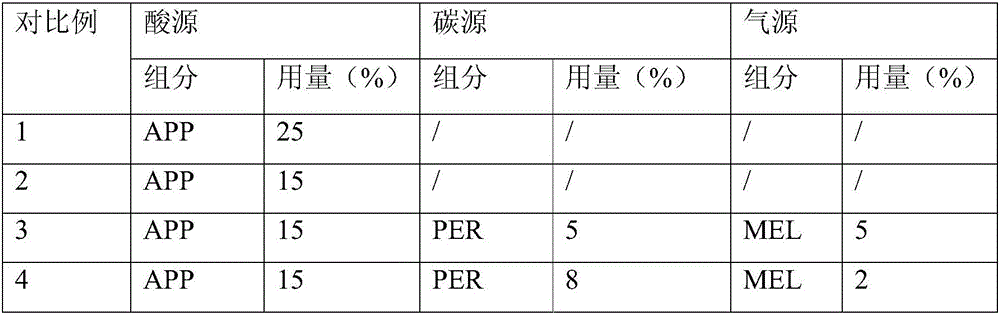

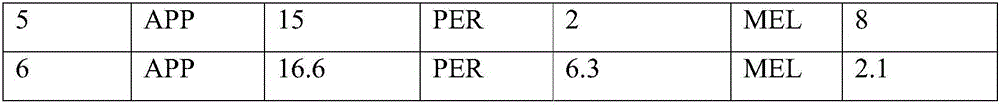

[0024] According to the ratio shown in Table 1, the acid source, carbon source, gas source, charring catalyst and water that make up the catalytic carbonization intumescent flame retardant system were added to the colloid mill and ground for 4 hours to obtain a milky white viscous catalytic carbonization intumescent flame retardant system .

[0025] Table 1 Proportion of catalytic carbonization expansion flame retardant system

[0026]

[0027] In the table, APP—ammonium polyphosphate, PER—pentaerythritol, MEL—melamine, MPP—melamine pyrophosphate, Si-APP—silane-modified ammonium polyphosphate, the same below. (Example 12 test used melamine pyrophosphate—prepared by the reaction of sodium pyrophosphate and melamine, and the gas source has been included therein.)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com