Self-repairing anhydrous stemming

An anhydrous taphole clay and self-repairing technology, applied in the field of ferrosilicon production, can solve the problems of increasing the operating cost of the submerged arc furnace, short overhaul period of the submerged arc furnace, poor self-repairing performance, etc. The effect of smooth production and high refractoriness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

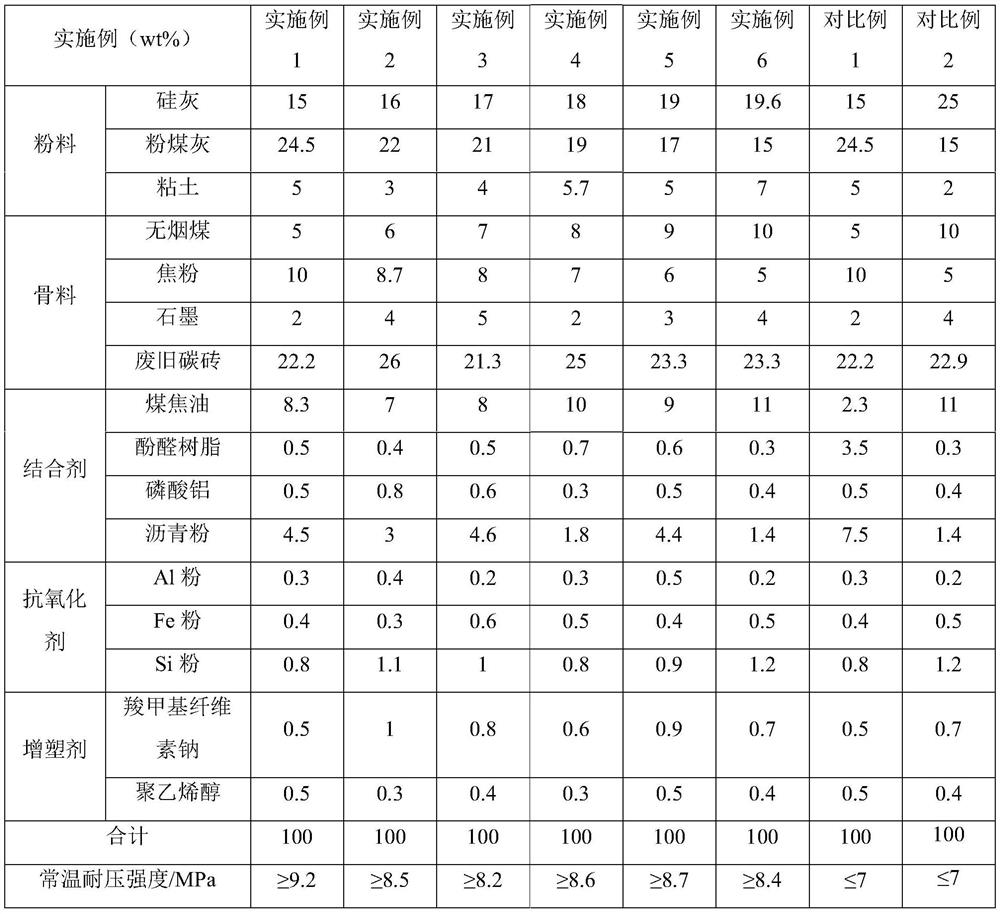

[0037] A specific embodiment of self-repairing waterless taphole cement of the present invention is provided below, but the present invention is not limited to the provided examples.

[0038] The gun clay in the embodiment of the present invention and comparative example adopts following preparation method to obtain:

[0039] Put the corresponding raw materials into the mixer according to the ratio, mix them evenly, enter the molding machine for pressing and molding, and leave it for 1 hour after molding to get the finished product.

[0040]

[0041] In comparative example 1, coal tar is 2.3%, less than the scope of 7-11% limited by the present invention, phenolic resin is 3.5%, greater than the scope of 0.3-0.7% limited by the present invention, asphalt powder is 7.5%, greater than the scope of this invention The range of 1.4-5% limited by the invention, at this time, the normal temperature compressive strength of the anhydrous taphole clay is not more than 7MPa, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com