Halogen-free flame retardant polyester material and preparation method thereof

A technology of flame-retardant polyester and polyester, which is applied in the manufacture of fire-retardant and flame-retardant filaments, and single-component polyester rayon. Unsatisfactory, large amount of flame retardant, etc., to achieve the effect of increasing the thickness of the carbonized layer and the amount of residual carbon, improving the insulation effect, and reducing the amount of smoke generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

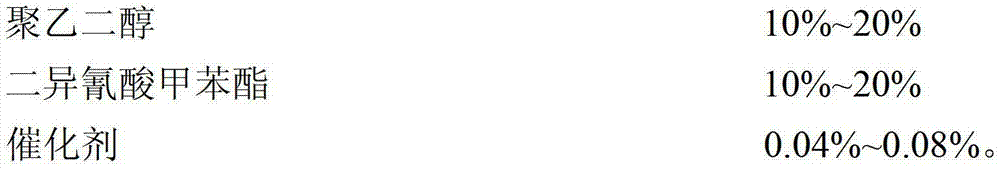

[0046] (1) Preparation of polyethylene glycol modified polyester: prepared by two-stage twin-screw extrusion equipment, and 7.996 mol polyethylene terephthalate (Rongsheng Petrochemical, fiber grade filament PET polyester chips) , 1mol of toluene diisocyanate, 0.0013mol of dibutyltin maleate are mixed uniformly at a low temperature and high speed (5000 revolutions per minute) at 20℃, and then extruded through first-stage co-directional parallel blending (first-stage extrusion temperature 242.5℃ ±7.5℃); then add 1mol polyethylene glycol (average molecular weight 10000) and 0.0027mol catalyst dibutyltin maleate at the feeding port of the second-stage extrusion, and granulate through the second-stage co-directional parallel blending and extrusion (two Step extrusion temperature is 245℃±5℃) to obtain polyethylene glycol modified polyester.

[0047] (2) Preparation of flame retardant: the average particle size of 1kg is 200nm and the CEC is 1mmol·g -1 The sodium-based montmorillonite ...

Embodiment 2

[0051] (1) Preparation of polyethylene glycol modified polyester: Prepared by two-stage twin-screw extrusion equipment, 5.992mol polytrimethylene terephthalate (Rongsheng Petrochemical, fiber grade filament PTT polyester chips), 2mol Toluene diisocyanate and 0.0026mol dibutyltin maleate are mixed uniformly at a low temperature and high speed (5000 rpm) at 15℃, and then extruded through first-stage co-directional parallel blending (first-stage extrusion temperature 242.5℃±7.5 ℃); then add 2mol polyethylene glycol (average molecular weight 8000) and 0.0054mol catalyst dibutyl tin maleate at the feeding port of the second-stage extrusion, and granulate through the second-stage co-directional parallel blending and extrusion (two-stage extrusion) The output temperature is 245℃±5℃) to obtain polyethylene glycol modified polyester.

[0052] (2) Preparation of flame retardant: the average particle size of 1kg is 200nm and the CEC is 1mmol·g -1 The sodium-based montmorillonite is uniforml...

Embodiment 3

[0056] (1) Preparation of polyethylene glycol modified polyester: prepared by a two-stage twin-screw extrusion equipment, 6.794mol polybutylene terephthalate (Rongsheng Petrochemical, fiber grade filament PBT polyester chip) , 1.6mol of toluene diisocyanate, 0.002mol of dibutyltin maleate, mixed uniformly at 10℃, low temperature and high speed (5000 revolutions / min), and extruded through first-order co-directional parallel blending (first-order extrusion temperature 242.5 ℃±7.5℃); Then add 1.6mol polyethylene glycol (average molecular weight 10000) and 0.004mol catalyst dibutyltin maleate at the feeding port of the second-stage extrusion, and granulate through the second-stage co-directional parallel blending and extrusion (The second-stage extrusion temperature is 245℃±5℃), and the polyethylene glycol modified polyester is prepared.

[0057] (2) Preparation of flame retardant: the average particle size of 1kg is 200nm and the CEC is 1mmol·g -1 The sodium-based montmorillonite is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com