Metal loaded activated carbon modified silk protein porous membrane and preparation and application methods thereof

A fibroin and metal-loading technology, applied in the field of textile materials, can solve the problem of high cost of precious metals, and achieve the effects of more active points, high residual carbon content, and increased adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

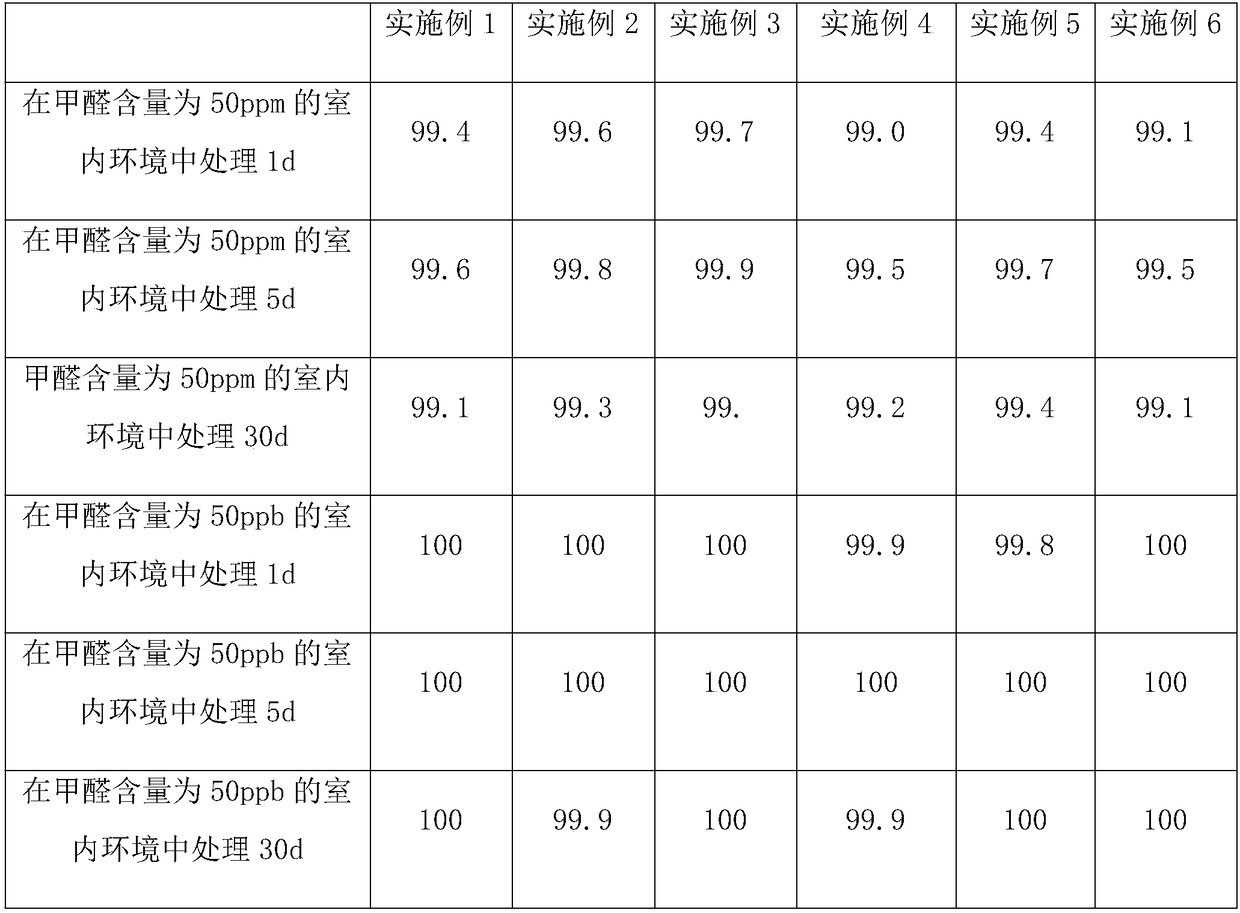

Examples

Embodiment 1

[0025] (1) Take the peripheral fibers of the loofah as raw materials, and process the raw materials so that the thickness is not higher than 2mm, and the area is not larger than 10mm 2 Sheet material, at 20 ℃, pretreatment in 5% sodium hydroxide solution for 5min, then completely immersed in the furfuryl alcohol solution containing metal salt, wherein, the furfuryl alcohol solution containing metal salt contains 8wt% oxalic acid, 5wt% Gold and manganese metal salts, the balance is furfuryl alcohol, 10L / h of nitrogen gas is passed into the solution to form tiny bubbles with a diameter of no more than 1cm, soak for 30min, take it out, squeeze to remove excess furfuryl alcohol solution, and dry at 80°C After curing for 1 hour, place it at 800° C. for high-temperature carbonization treatment for 60 minutes to obtain a loofah-based sheet-like activated carbon material.

[0026] (2) Mix the loofah-based sheet-shaped activated carbon material with a mass ratio of 1:5 and the silk pro...

Embodiment 2

[0028] (1) Take the peripheral fibers of the loofah as raw materials, and process the raw materials so that the thickness is not higher than 2mm, and the area is not larger than 10mm 2Sheet material, at 60 ℃, pretreatment in 10% sodium hydroxide solution for 15min, then completely immersed in the furfuryl alcohol solution containing metal salt, wherein, the furfuryl alcohol solution containing metal salt contains 16wt% oxalic acid, 15wt% Platinum and cerium metal salt, the balance is furfuryl alcohol, 30L / h of nitrogen gas is passed into the solution to form tiny bubbles with a diameter of no more than 1cm, soak for 60min, take it out, squeeze to remove excess furfuryl alcohol solution, and dry at 140°C After curing for 3 hours, place it at 900° C. for high-temperature carbonization treatment for 90 minutes to obtain a loofah-based sheet-like activated carbon material.

[0029] (2) Mix the loofah base sheet-shaped activated carbon material with a mass ratio of 1:10 and the sil...

Embodiment 3

[0031] (1) Take the peripheral fibers of the loofah as raw materials, and process the raw materials so that the thickness is not higher than 2mm, and the area is not larger than 10mm 2 Sheet material, at 45 ℃, pretreatment in 6% sodium hydroxide solution for 10min, then completely immersed in the furfuryl alcohol solution containing metal salt, wherein, the furfuryl alcohol solution containing metal salt contains 12wt% oxalic acid, 10wt% Palladium and titanium metal salt, the balance is furfuryl alcohol, 20L / h of nitrogen gas is passed into the solution to form micro bubbles with a diameter of no more than 1cm, soak for 45min, take it out, squeeze to remove excess furfuryl alcohol solution, and dry at 100°C After curing for 2 hours, place it at 850° C. for high-temperature carbonization treatment for 75 minutes to obtain a loofah-based sheet-like activated carbon material.

[0032] (2) Mix the loofah base sheet-shaped activated carbon material with a mass ratio of 1:6 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com