Residual oil modified fire retardation agent composition and fire retardation polyolefin material prepared from the same

A flame retardant and composition technology, which is applied in the field of residual oil modified flame retardant composition and its preparation, can solve the problems of unimproved dispersibility, poor compatibility of organic polymer materials, etc., and achieves high phosphorus content. , the structure is stable, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 N, N-dimethylformamide solution and phosphorus oxychloride molar ratio 1.5: 1 are formulated into Vilsmeier reagent, then 10-20 mass parts are added the aromatic component separated by heavy residual oil to 80 -In 100 parts of Vilsmeier reagent, stir evenly, heat the mixture to about 95°C within 30 minutes, and wait until the reaction is complete. Hydrolyze the unreacted phosphorus oxychloride with ice water, and then separate the yellow viscous aromatic aldehyde product by column chromatography; slowly add 50-75 mass parts of sodium borohydride to 10-15 mass parts of aromatic aldehyde, React for about 5 hours. Add ice water to hydrolyze excess sodium borohydride, distill off the solvent to obtain the aromatic alcohol; carefully pour phosphorus oxychloride into the aromatic alcohol in batches at a molar ratio of 1:1, wait for white crystals to form, filter off the solvent, The white crystals were filtered and dried under reduced pressure to obtain a white ...

Embodiment 6

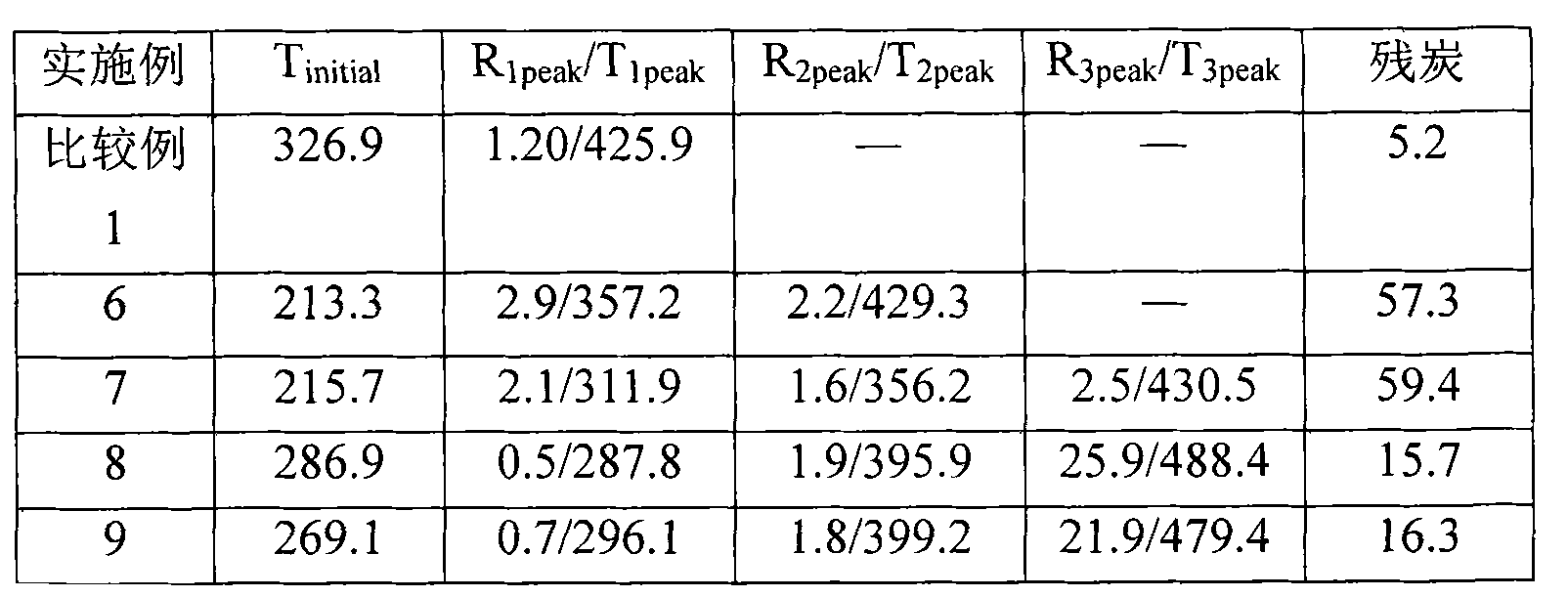

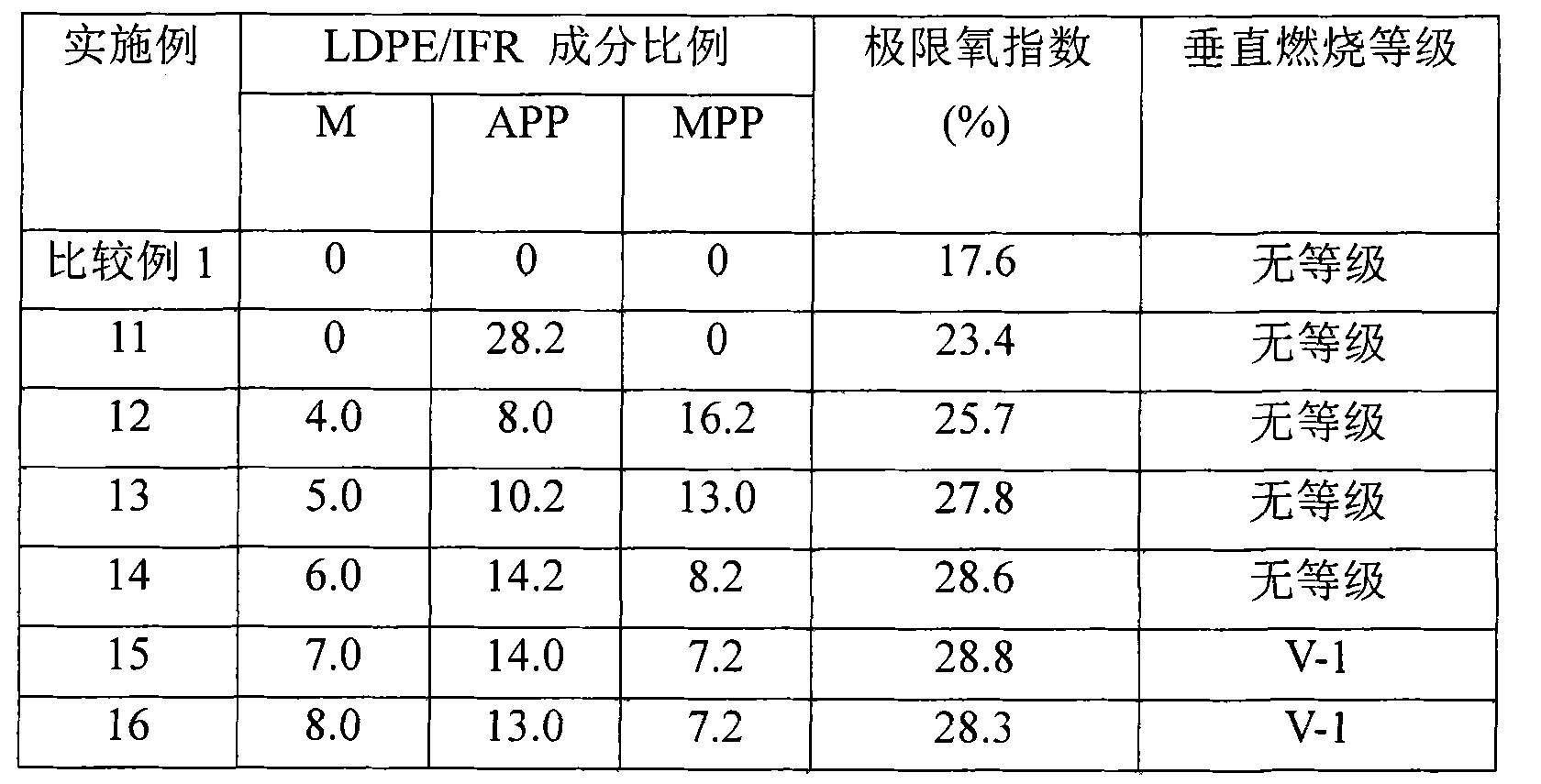

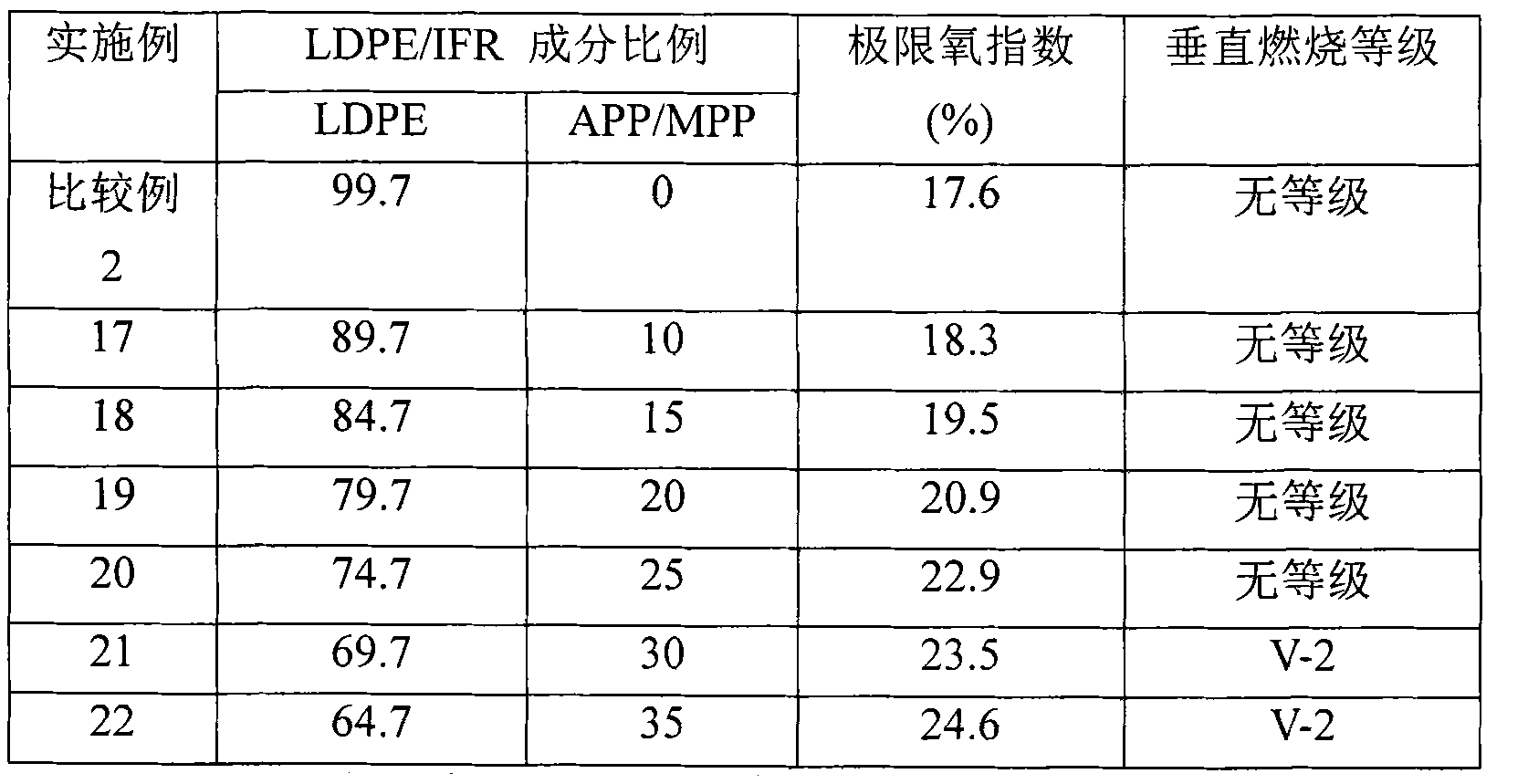

[0055] Example 6 Add ammonium polyphosphate and melamine polyphosphate into a high-speed mixer according to the mass ratio of 2:1, and mix at a high speed for 3-10 minutes to obtain a flame retardant composition of ammonium polyphosphate and melamine polyphosphate, and measure its performance, see Table 2.

Embodiment 7

[0056] Example 7 Add residual oil modified flame retardant, ammonium polyphosphate and melamine polyphosphate into the high-speed mixer according to the mass ratio (1-10): (2-5): (1-5) for 3-10 minutes After high-speed mixing, a composition of residual oil modified flame retardant, ammonium polyphosphate, and melamine polyphosphate flame retardant was obtained, and its properties were determined in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com