Synergistically modified APP (ammonium polyphosphate), preparation method for same and application to flame-retardant polypropylene

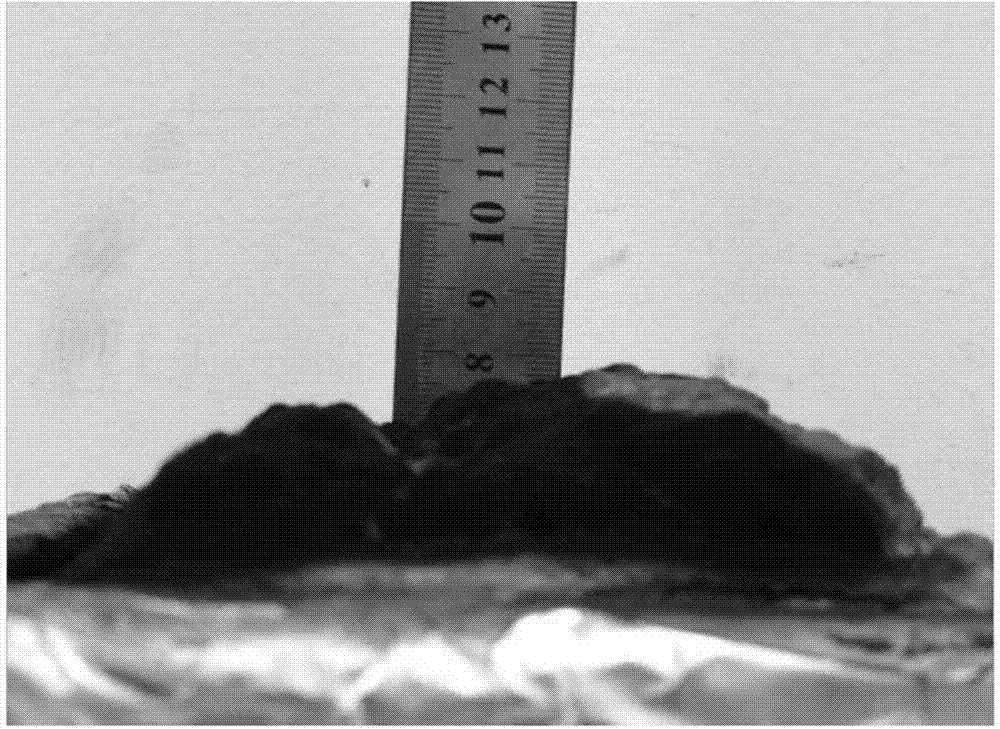

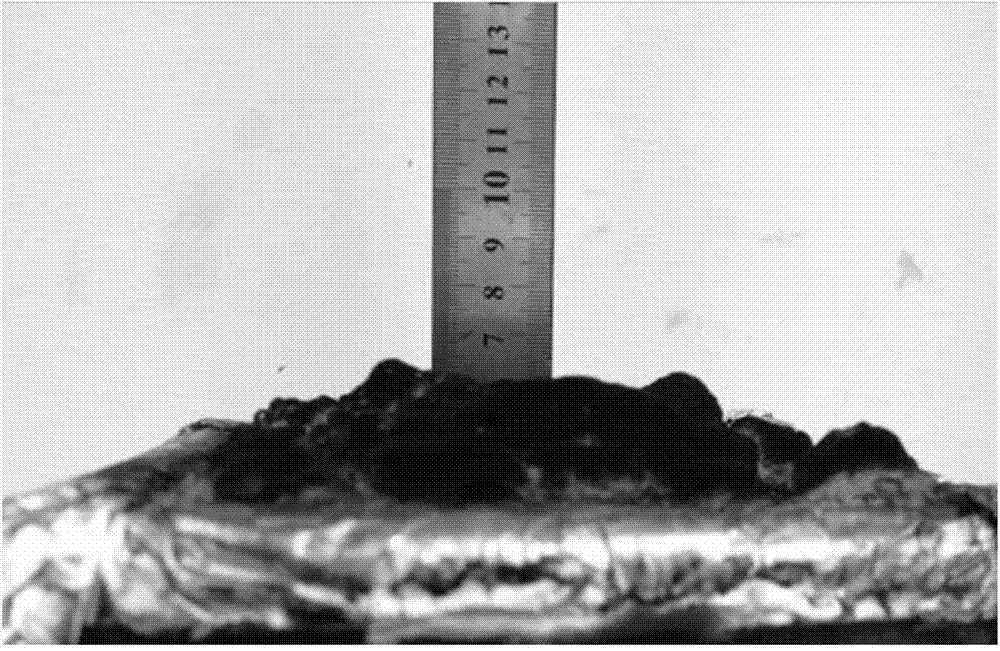

An ammonium polyphosphate and modified technology, applied in the field of flame retardant, can solve the problems of improved water resistance and flame retardant performance, unfavorable industrial application, increased system viscosity, etc., and achieves improved flame retardant performance, low cost, and carbon layer expansion. height increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Disperse 30 g of ammonium polyphosphate (APP, crystal type II) in 90 ml of absolute ethanol, stir evenly to obtain the dispersion of APP, and transfer to a 500 ml three-necked flask.

[0051] (2) Dissolve 1.5 g of aluminum chloride in 20 ml of distilled water to obtain a colorless and transparent solution.

[0052] (3) Under stirring, add the aluminum chloride solution dropwise to the dispersion of APP.

[0053] (4) Add 6 g of 25% ammonia water dropwise to the above mixed system, and the pH value at this time is 8.6. Raise the temperature to 50°C, 120min later, the reaction is complete, filter suction, wash off impurities, dry in an oven at 80°C, pulverize to obtain the surface modified APP-1 powder, and then water the obtained APP-1 powder Solubility test, and use TG for thermal stability analysis.

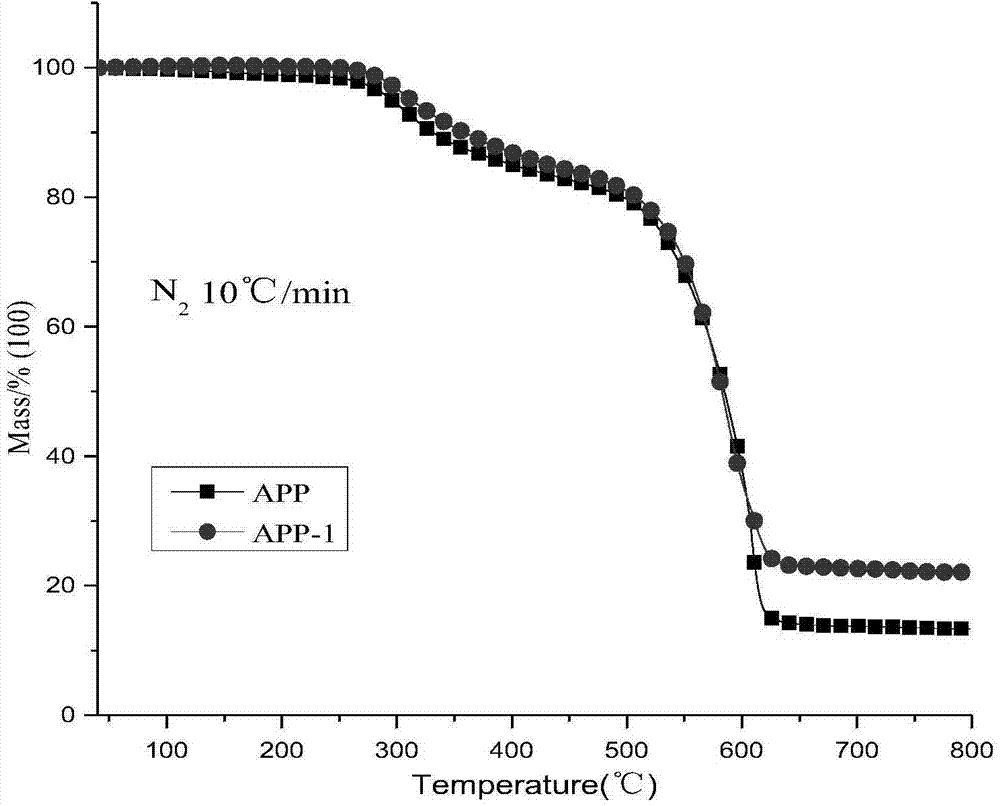

[0054] Test result: The water solubility of ammonium polyphosphate at 25°C decreased from 1.0135g / 100mL before modification to 0.2975g / 100mL after modification, a decrease of...

Embodiment 2

[0061] (1) Disperse 10 g of ammonium polyphosphate (APP, crystal type II) in 100 ml of isopropanol, stir evenly to obtain a dispersion of APP, and transfer to a 500 ml three-necked flask.

[0062] (2) Dissolve 2 g of aluminum sulfate in 20 ml of distilled water to obtain a colorless and transparent solution.

[0063] (3) While stirring, add the aluminum sulfate solution dropwise to the dispersion of APP.

[0064] (4) Add 5 g of 20% ammonia water dropwise to the above mixed system, and the pH value at this time is 8.7. Raise the temperature to 60°C, 100min later, the reaction is complete, suction filter, wash off impurities, dry in a 90°C oven, pulverize to obtain the surface modified APP-2 powder, and then water the obtained APP-2 powder Solubility test, and use TG for thermal stability analysis.

[0065] Test result: The water solubility of ammonium polyphosphate at 25°C decreased from 1.0135g / 100mL before modification to 0.3375g / 100mL after modification, a decrease of 67%. TG resu...

Embodiment 3

[0069] (1) Disperse 20 g of ammonium polyphosphate (APP, crystal type II) in 100 ml of absolute ethanol, stir evenly to obtain a dispersion of APP, and transfer to a 500 ml three-necked flask.

[0070] (2) Weigh 3g aluminum isopropoxide and dissolve it in 250ml anhydrous methanol.

[0071] (3) Under stirring, the methanol solution of aluminum isopropoxide was added dropwise to the dispersion of APP.

[0072] (4) Finally, add 2ml of distilled water dropwise. Raise the temperature to 85°C, after 60 minutes, the reaction is complete, filter with suction, wash off impurities, dry in an oven at 110°C, and finally pulverize to obtain modified APP-3. Then the obtained APP-2 powder was tested for water solubility, and TG was used for thermal stability analysis.

[0073] Test results: The water solubility of ammonium polyphosphate at 25°C decreased from 1.0135g / 100mL before modification to 0.2615g / 100mL after modification, a decrease of 74%. TG results under nitrogen atmosphere showed that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water solubility | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com