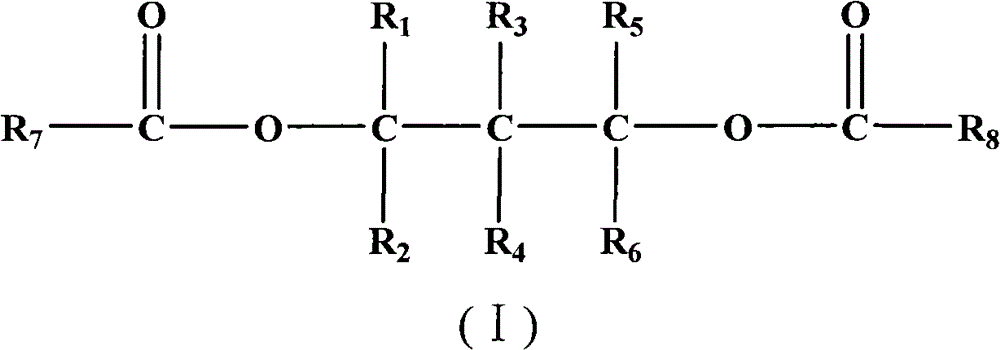

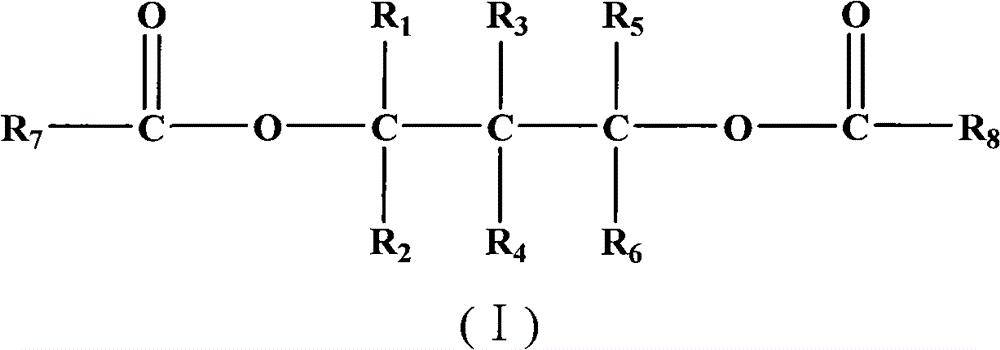

Catalyst component for olefin polymerization and catalyst thereof

An olefin polymerization and catalyst technology, which is applied in the field of olefin polymerization catalyst components and catalysts, can solve the problems of low melt flow index, etc., and achieve the effects of good hydrogen adjustment sensitivity, high melt flow rate, and high tactic index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of catalyst solid components

[0042] In a 250ml reactor equipped with a reflux condenser, a mechanical stirrer and a thermometer and fully replaced by nitrogen, add 36.5ml of absolute ethanol, 21.3g of anhydrous magnesium chloride, heat up under stirring, and add 75ml of white oil after the magnesium chloride is completely dissolved. Silicone oil 75ml, maintain 120 ℃ for a certain period of time. In another reaction bottle with a volume of 500ml and a high-speed stirrer, 112.5ml of white oil and the same volume of silicone oil were added in advance, preheated to 120°C, and the aforementioned mixture was quickly pressed into the second reactor and maintained at 120°C. °C was stirred at 3500rmp for 3 minutes, and under stirring, the material was transferred to the third reactor that had previously added 1600ml of hexane and cooled to -25 °C until the material transfer was completed, and the final temperature did not exceed 0 °C. Suction filtration, washi...

Embodiment 2

[0047] Same as Example 1, except that 0.9 g of tributyl phosphate was added. Aggregated data are shown in Table 1.

Embodiment 3

[0049] Same as Example 1, except that 3.8 g of triethyl phosphate was added. Aggregated data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com