Phenyl phosphate flame retardant containing DOPO, and preparation method and application thereof

A technology of phenyl phosphate and flame retardants, applied in the field of phenyl phosphate flame retardants, can solve problems such as the inability to meet the processing temperature of polymer materials, and achieve the effects of easy industrial production, advanced technology, and high phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

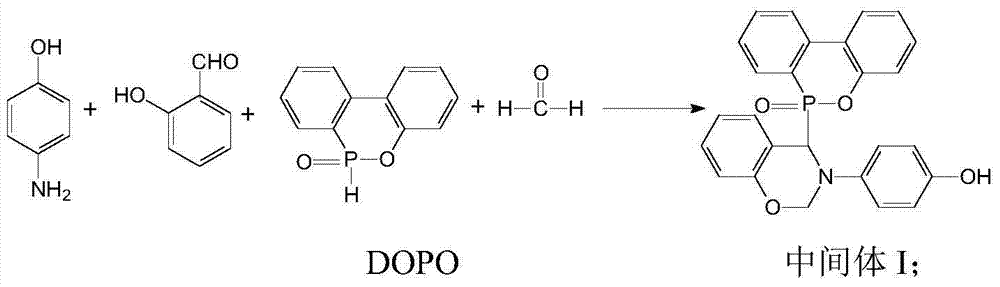

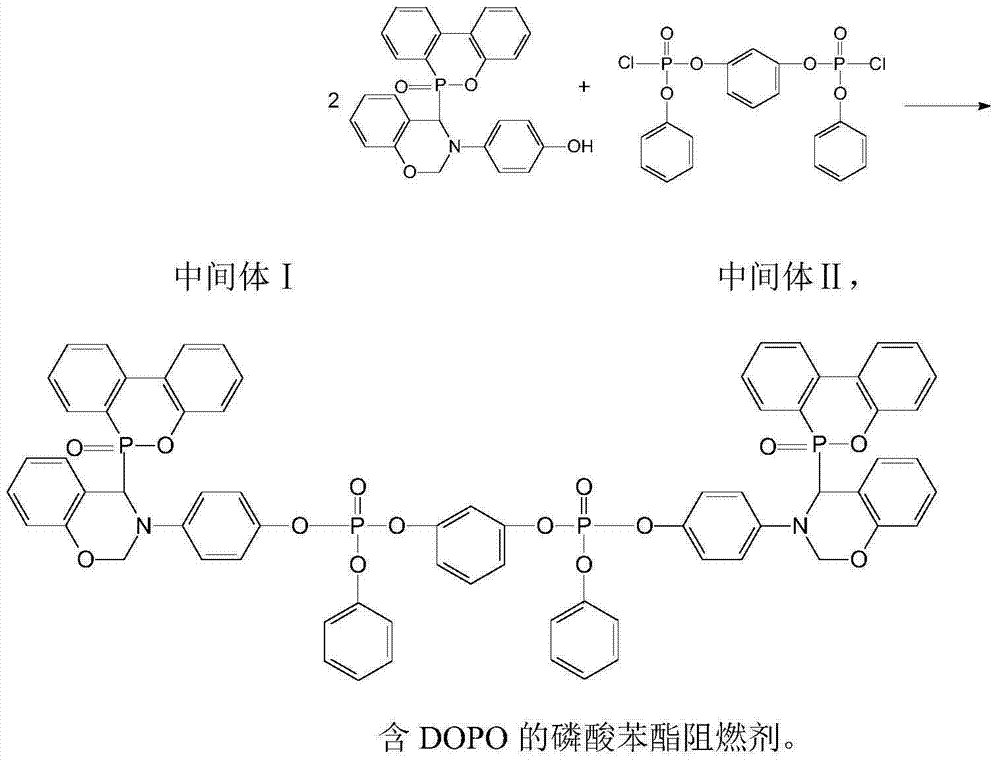

[0027] A preparation method of DOPO-containing phenyl phosphate flame retardant, the steps are:

[0028] Add 13.10 g (0.12 mol) of 4-aminophenol, 14.66 g (0.12 mol) of 2-hydroxybenzaldehyde, 25.94 g (0.12 mol) of DOPO, and 250 mL of methanol into a flask equipped with a stirrer, a reflux condenser and a tail gas absorber. Nitrogen gas was introduced, and after 10 hours of reaction at room temperature, 9.84 g (0.12 mol) of 37% formaldehyde was added, and the reaction was carried out at room temperature for 6 hours. After the reaction, the reaction solution was poured into 300 mL of water, and a large amount of white solid was precipitated, which was filtered by suction and dried in vacuum to obtain Intermediate I with a yield of 91.2%.

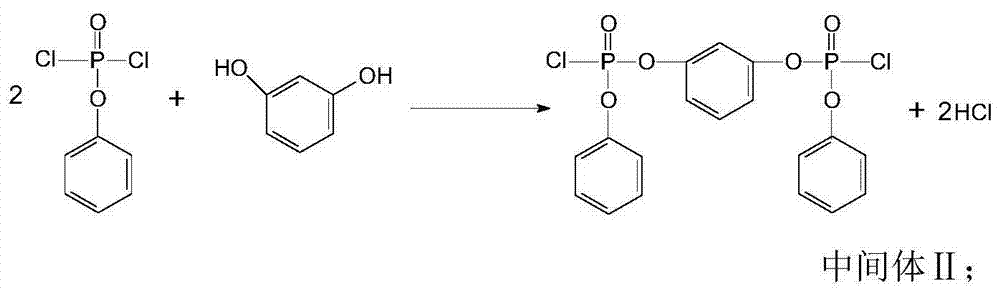

[0029] In the flask equipped with stirrer, reflux condenser and tail gas absorbing device, add 50.64g (0.24mol) phenoxyphosphoryl dichloride, start stirring, 13.2g (0.12mol) resorcinol and 101.28g (0.48 mol) phenoxyphosphoryl dichloride was ad...

Embodiment 2

[0037] A preparation method of DOPO-containing phenyl phosphate flame retardant, the steps are:

[0038]Add 13.10 g (0.12 mol) of 4-aminophenol, 14.66 g (0.12 mol) of 2-hydroxybenzaldehyde, 25.94 g (0.12 mol) of DOPO, and 260 mL of acetonitrile into a flask equipped with a stirrer, a reflux condenser, and a tail gas absorption device. Nitrogen gas was introduced, and after 10 hours of reaction at room temperature, 9.84 g (0.12 mol) of 37% formaldehyde was added, and the reaction was carried out at room temperature for 6 hours. After the reaction, the reaction solution was poured into 300 mL of water, and a large amount of white solid was precipitated, which was filtered by suction and dried in vacuum to obtain Intermediate I with a yield of 91.2%.

[0039] In the flask equipped with stirrer, reflux condenser and tail gas absorbing device, add 50.64g (0.24mol) phenoxyphosphoryl dichloride, start stirring, 13.2g (0.12mol) resorcinol and 101.28g (0.48 mol) phenoxyphosphoryl dich...

Embodiment 3

[0043] A preparation method of DOPO-containing phenyl phosphate flame retardant, the steps are:

[0044] Add 13.10 g (0.12 mol) of 4-aminophenol, 14.66 g (0.12 mol) of 2-hydroxybenzaldehyde, 25.94 g (0.12 mol) of DOPO, and 250 mL of methanol into a flask equipped with a stirrer, a reflux condenser and a tail gas absorber. Nitrogen gas was introduced, and after 10 hours of reaction at room temperature, 9.84 g (0.12 mol) of 37% formaldehyde was added, and the reaction was carried out at room temperature for 6 hours. After the reaction, the reaction solution was poured into 300 mL of water, and a large amount of white solid was precipitated, which was filtered by suction and dried in vacuum to obtain Intermediate I with a yield of 91.2%.

[0045] In the flask equipped with stirrer, reflux condenser and tail gas absorbing device, add 50.64g (0.24mol) phenoxyphosphoryl dichloride, start stirring, 13.2g (0.12mol) resorcinol and 101.28g (0.48 mol) phenoxyphosphoryl dichloride was ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com