Phosphorus-containing crosslinked gel polymer electrolyte and on-site thermal-polymerization preparation method and application thereof

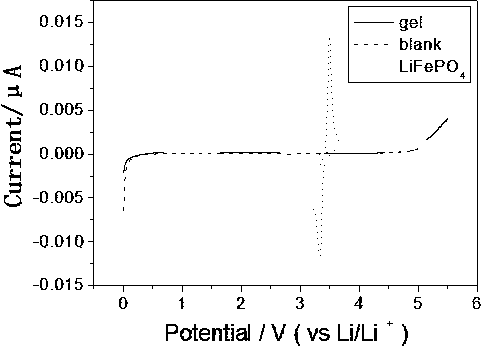

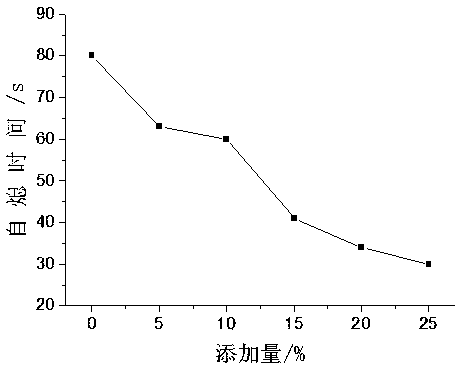

A cross-linked gel and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of low mechanical strength, high operating conditions, assembly and use requirements, etc., and achieve good electrochemical stability , high ionic conductivity, and the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

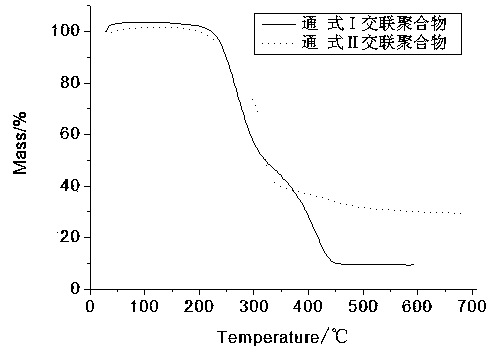

[0036] Embodiment 1: corresponding preparation general formula Ⅳ

[0037] Diethyl allyl phosphate (formula Ⅰ) 1.0 g, triethylene glycol dimethacrylate 0.7 g, AIBN 0.0075 g, lithium ion battery liquid electrolyte (the electrolyte is lithium hexafluorophosphate, the concentration is 1M, the solvent is ethylene carbonate ester and diethyl carbonate (1:1, v%)) 8.3 g, mixed evenly and reacted at 75 °C for 1 h under the protection of nitrogen to obtain a transparent, uniform, soft gel polymer electrolyte, at 25 °C The measured conductivity was 6.95 ms / cm.

[0038]

Embodiment 2

[0039] Embodiment 2: corresponding preparation general formula Ⅳ

[0040] 2-acryloyloxyethyl phosphate diethyl ester (general formula II) 1.0 g, triethylene glycol diacrylate 0.5 g, AIBN 0.0075 g, lithium-ion battery liquid electrolyte (electrolyte is lithium hexafluorophosphate, concentration is 1M, solvent It is 8.5 g of ethylene carbonate and dimethyl carbonate (1:1, v%), mixed evenly, and reacted at 75 °C for 1 h under nitrogen protection to obtain transparent, uniform, viscous, elastic, and good mechanical properties. Gel polymer electrolyte, the conductivity measured at 25 ℃ is 7.86 ms / cm.

[0041]

Embodiment 3

[0042] Embodiment 3: corresponding preparation general formula Ⅳ

[0043] Diethyl butenyl phosphonate (general formula III) 1.0 g, triethylene glycol dimethacrylate 0.5 g, AIBN 0.0075 g, liquid electrolyte for lithium-ion batteries (the electrolyte is lithium hexafluorophosphate, the concentration is 1M, the solvent is carbonic acid Vinyl ester and dimethyl carbonate (1:1, v%)) 8.5 g, after mixing evenly, under the protection of nitrogen, react at 75 ℃ for 1 h to obtain a transparent, uniform, and mechanically good gel polymer electrolyte. The conductivity measured at °C was 8.58 ms / cm.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com