Combustion-resisting electrolyte of lithium secondary cell and its lithium cell

A lithium secondary battery and electrolyte technology, applied in the field of electrochemical and chemical power supply products, can solve the problems of high freezing point, great impact on battery performance, low lithium salt solubility, etc., and achieve the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

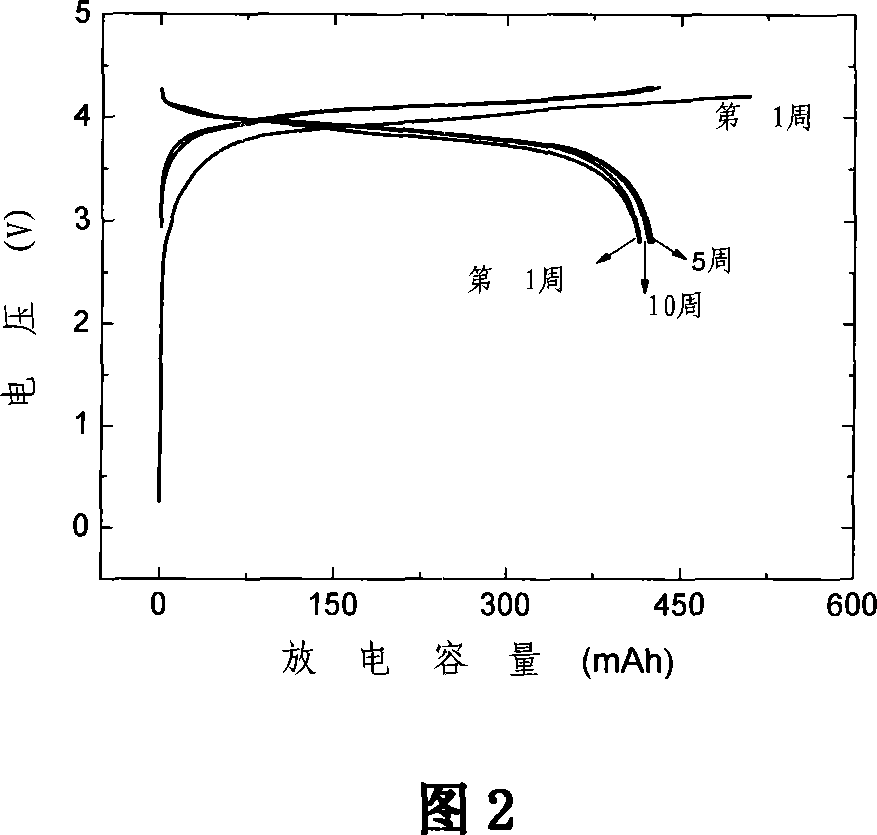

[0034] Lithium bisoxalate borate (LiBOB) and 10% VC were added to dimethyl methyl phosphate (DMMP) to form a 0.6M LiBOB+DMMP solution. Inject the electrolyte into graphite / LiCoO 2 Charge and discharge experiments were carried out in the battery (as shown in Figure 2). It can be seen from the figure that the efficiency in the first week can reach 86%, which is close to the initial efficiency of the traditional carbonate electrolyte, and the cycle performance is good.

Embodiment 2

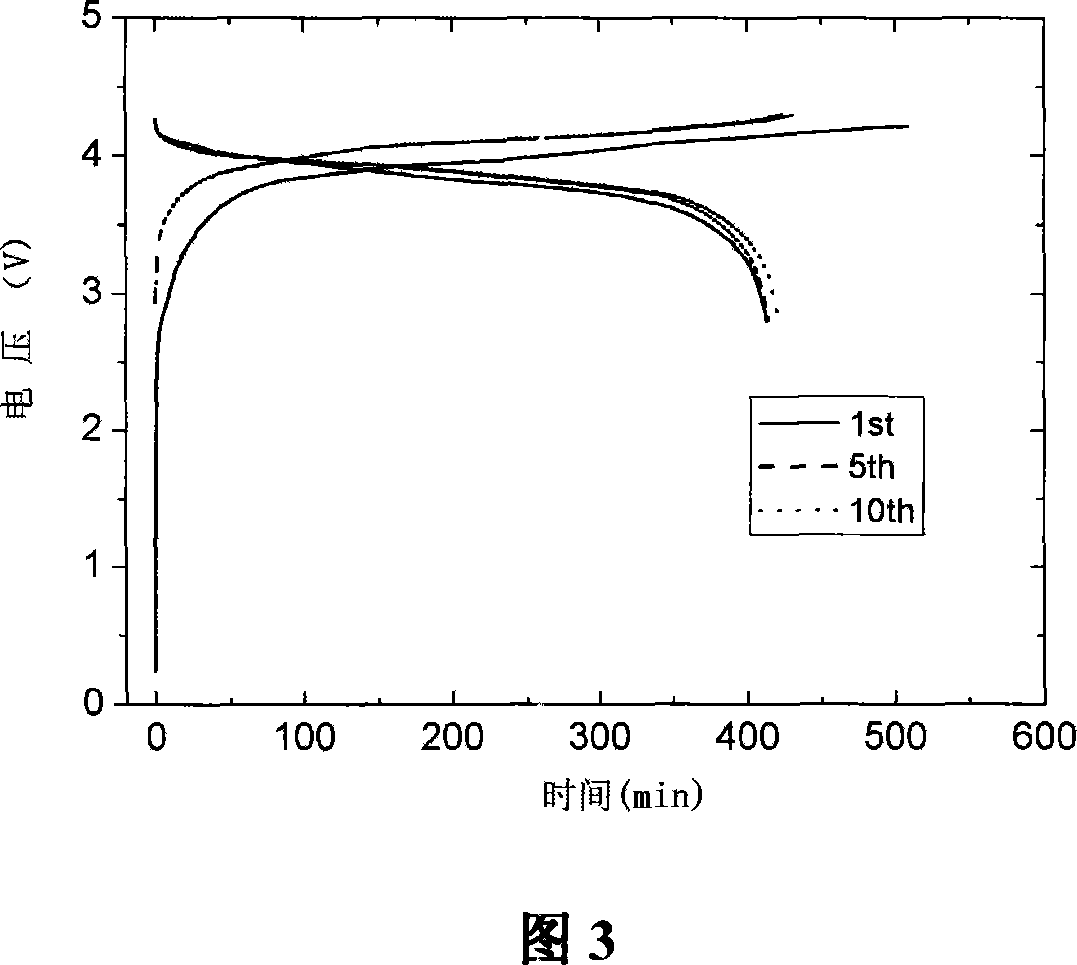

[0036] At 1M LiPF 6 / EC-DMC (1:1) solution was added with 20% diethyl ethyl phosphate. The electrolyte solution is added into a commercial LiMn2O4-C lithium ion battery. It can be seen from Figure 3 that, except for a slight decrease in the charge-discharge efficiency of the battery in the first week (~84%), the charge-discharge efficiency of the battery subsequently rises rapidly to ~100%, and the charge-discharge voltage platform is exactly the same as that without the flame retardant. It shows that this flame retardant can also be used as a safety additive in practical batteries.

Embodiment 3

[0037] Example 3: Lithium hexafluorophosphate (LiPF 6 ) into 0.6M Li LiPF 6 +DMMP+DEMP solution. Inject the electrolyte into commercial graphite / LiCoO 2 In batteries, the prepared commercial graphite / LiCoO 2 Initial efficiency was -84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com