Grapheme/electroconductive polymer composite and preparation method thereof

A technology of conductive polymer and composite material, applied in the field of graphene/conductive polymer composite material and its preparation, can solve the problem that the stability of graphene/polyaniline composite material cannot be guaranteed, and achieve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

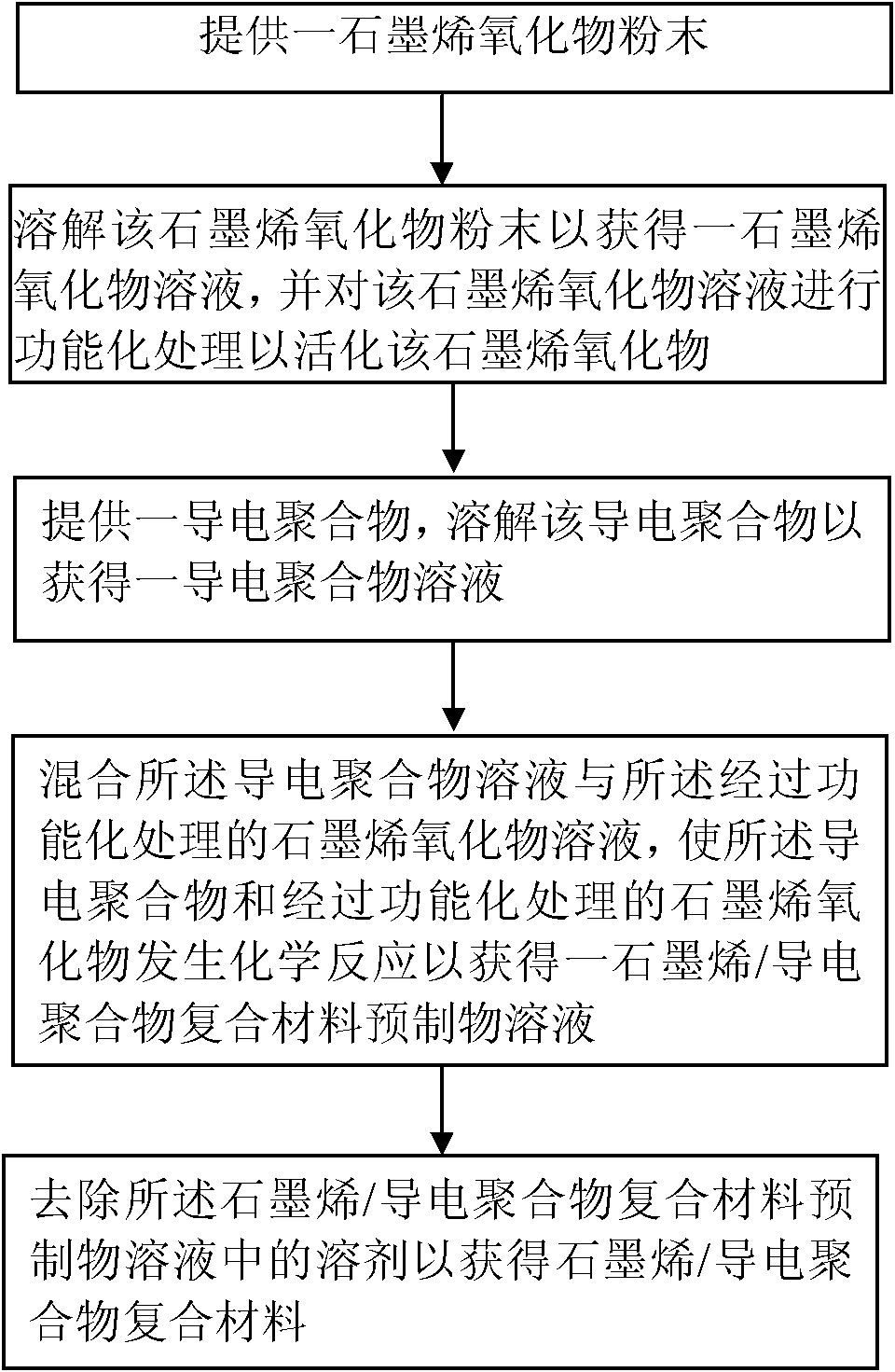

Method used

Image

Examples

Embodiment 1

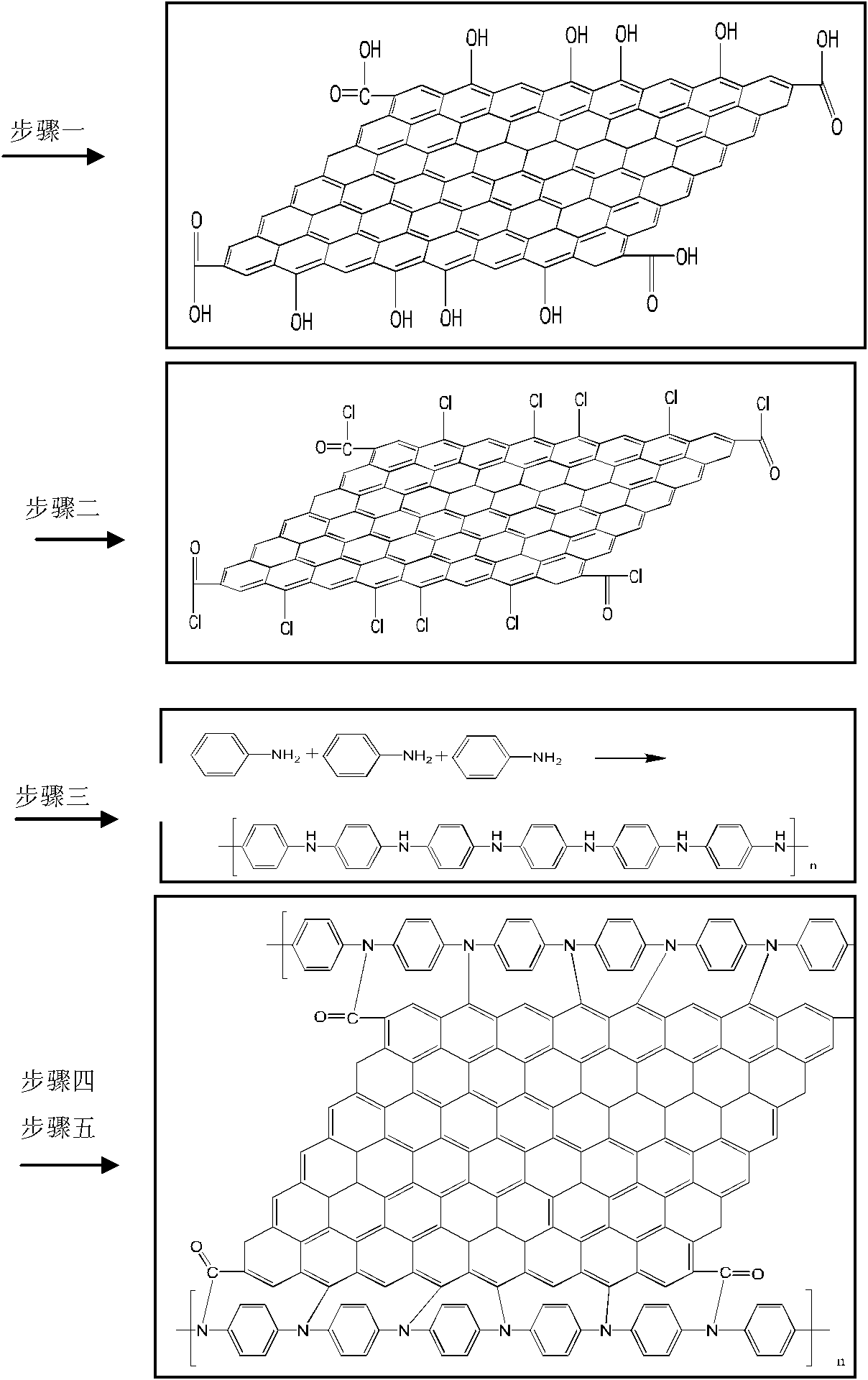

[0036] Step 1: provide a graphene oxide powder; that is: disperse 5 grams of flake natural graphite into 100 milliliters of concentrated sulfuric acid to form a mixture, and stir the mixture at a high speed in the process; add 10 grams to the above mixture within 1 hour Potassium permanganate powder, keep the mixture mixed with potassium permanganate in ice bath to keep its temperature not exceeding 3°C; after the addition of potassium permanganate is completed, remove the ice bath and slowly add 400 ml of deionized water, then The solution is heated to raise the temperature of the solution to 100°C, and kept at the temperature of 100°C for 1 hour, so that the graphite powder, potassium permanganate powder and sulfuric acid fully react to form graphite oxide; after the reaction, dilute and filter And wash the graphite oxide, then the concentration of 5% Na 2 CO 3 The solution was added to the graphite oxide and stirred to become a homogeneous solution, by adding a concentrati...

Embodiment 2

[0042] Step 1: provide a graphene oxide powder; namely: disperse 5 grams of scaly natural graphite into 230 milliliters of concentrated sulfuric acid to form a mixture, and stir the mixture at a high speed during this process; add 30 grams to the above mixture within 1 hour Potassium permanganate powder, keep the mixture mixed with potassium permanganate in ice bath to keep its temperature not exceeding 3°C; after the addition of potassium permanganate is completed, remove the ice bath and slowly add 400 ml of deionized water, then The solution is heated to raise the temperature of the solution to 100°C, and kept at the temperature of 100°C for 1 hour, so that the graphite powder, potassium permanganate powder and sulfuric acid fully react to form graphite oxide; after the reaction, dilute and filter and wash the graphite oxide, then use a concentration of 5% Na 2 CO 3 The solution dissolves the graphite oxide into a homogeneous solution, and through the added Na 2 CO 3 The...

Embodiment 3

[0048] Step 1: provide a graphene oxide powder; namely: disperse 5 grams of scaly natural graphite into 230 milliliters of concentrated sulfuric acid to form a mixture, and stir the mixture at a high speed during this process; add 30 grams to the above mixture within 1 hour Potassium permanganate powder, keep the mixture mixed with potassium permanganate in ice bath to keep its temperature not exceeding 3°C; after the addition of potassium permanganate is completed, remove the ice bath and slowly add 400 ml of deionized water, then The solution is heated to raise the temperature of the solution to 100°C, and kept at the temperature of 100°C for 1 hour, so that the graphite powder, potassium permanganate powder and sulfuric acid fully react to form graphite oxide; after the reaction, dilute and filter and wash the graphite oxide, then dissolve the graphite oxide in water, and then add a concentration of 5% Na 2 CO 3 The pH value of the solution is 6, and the solution is ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com